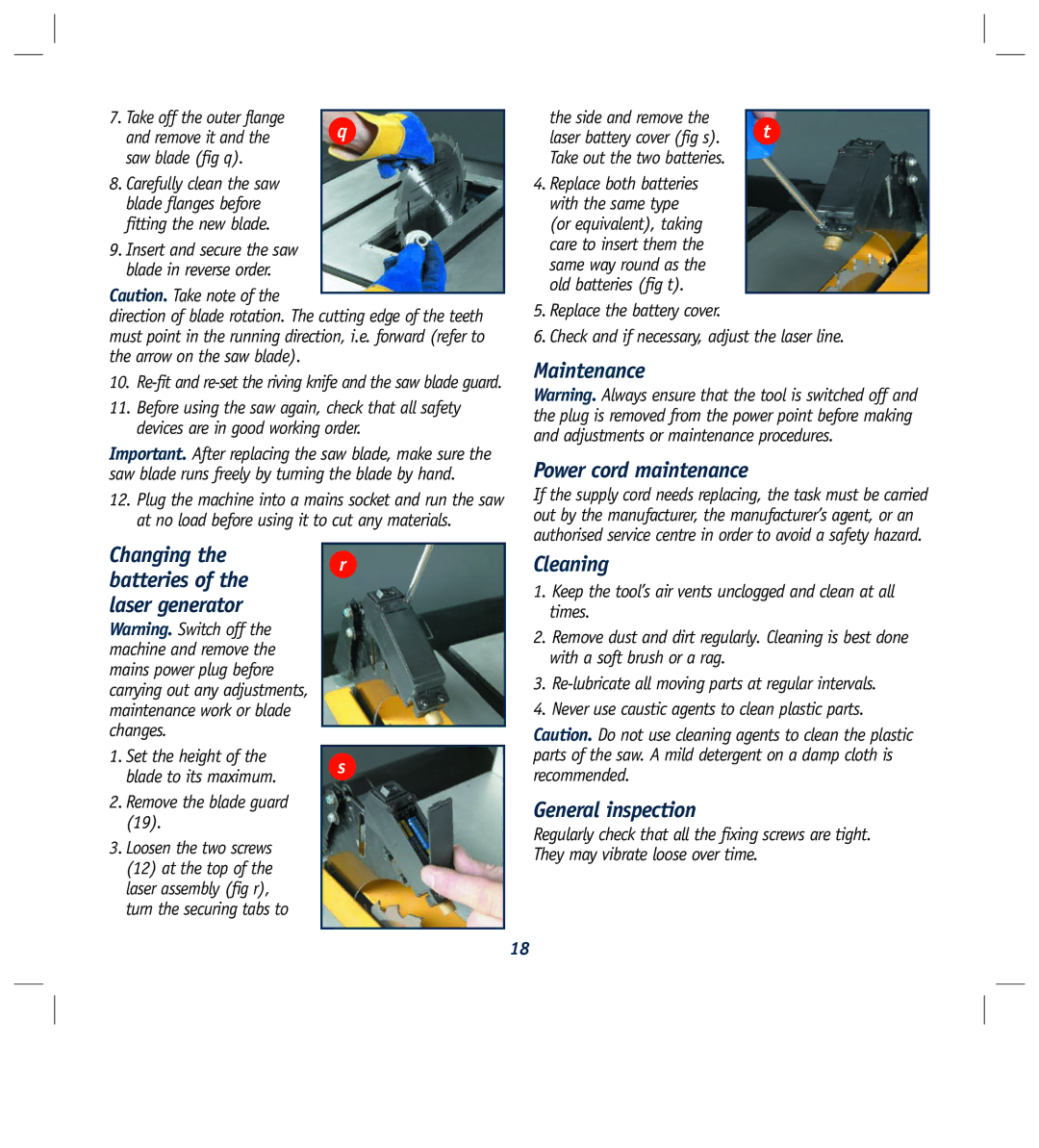

7. Take off the outer flange |

| |

q | ||

and remove it and the | ||

saw blade (fig q). |

|

8.Carefully clean the saw blade flanges before fitting the new blade.

9.Insert and secure the saw blade in reverse order.

Caution. Take note of the

direction of blade rotation. The cutting edge of the teeth must point in the running direction, i.e. forward (refer to the arrow on the saw blade).

10.

11.Before using the saw again, check that all safety devices are in good working order.

Important. After replacing the saw blade, make sure the saw blade runs freely by turning the blade by hand.

12.Plug the machine into a mains socket and run the saw at no load before using it to cut any materials.

Changing the | r | |

batteries of the | ||

| ||

laser generator |

|

Warning. Switch off the machine and remove the mains power plug before carrying out any adjustments, maintenance work or blade changes.

1. Set the height of the | s | |

blade to its maximum. | ||

|

2.Remove the blade guard

3.Loosen the two screws

(12)at the top of the laser assembly (fig r), turn the securing tabs to

the side and remove the

laser battery cover (fig s). t Take out the two batteries.

4.Replace both batteries with the same type (or equivalent), taking care to insert them the same way round as the old batteries (fig t).

5.Replace the battery cover.

6.Check and if necessary, adjust the laser line.

Maintenance

Warning. Always ensure that the tool is switched off and the plug is removed from the power point before making and adjustments or maintenance procedures.

Power cord maintenance

If the supply cord needs replacing, the task must be carried out by the manufacturer, the manufacturer’s agent, or an authorised service centre in order to avoid a safety hazard.

Cleaning

1.Keep the tool’s air vents unclogged and clean at all times.

2.Remove dust and dirt regularly. Cleaning is best done with a soft brush or a rag.

3.

4.Never use caustic agents to clean plastic parts.

Caution. Do not use cleaning agents to clean the plastic parts of the saw. A mild detergent on a damp cloth is recommended.

General inspection

Regularly check that all the fixing screws are tight. They may vibrate loose over time.

18