Important Points

Your new Globe mixer will provide years of uninterrupted service, but only if you do the following.

Installation

•Do not use an extension cord to connect electrical power.

•Make sure all 3 Phase units (see data plate) run in the direction of the arrow on front of the machine.

Operation

•Turn off the mixer prior to changing speeds.

•Follow the capacity chart on page 13, especially for mixing dough.

•Use only first (1) speed for mixing dough. 2nd speed should never be used on 50% AR or lower with the exception of the SP60P. The SP60P requires a 50% reduction in batch size to mix in speed 2 with 50% AR doughs.

•If the unit shuts off during mixing (overload protection trips), reduce the batch size.

Maintenance

•Add only 2 pumps of grease to the planetary grease fitting once a year.

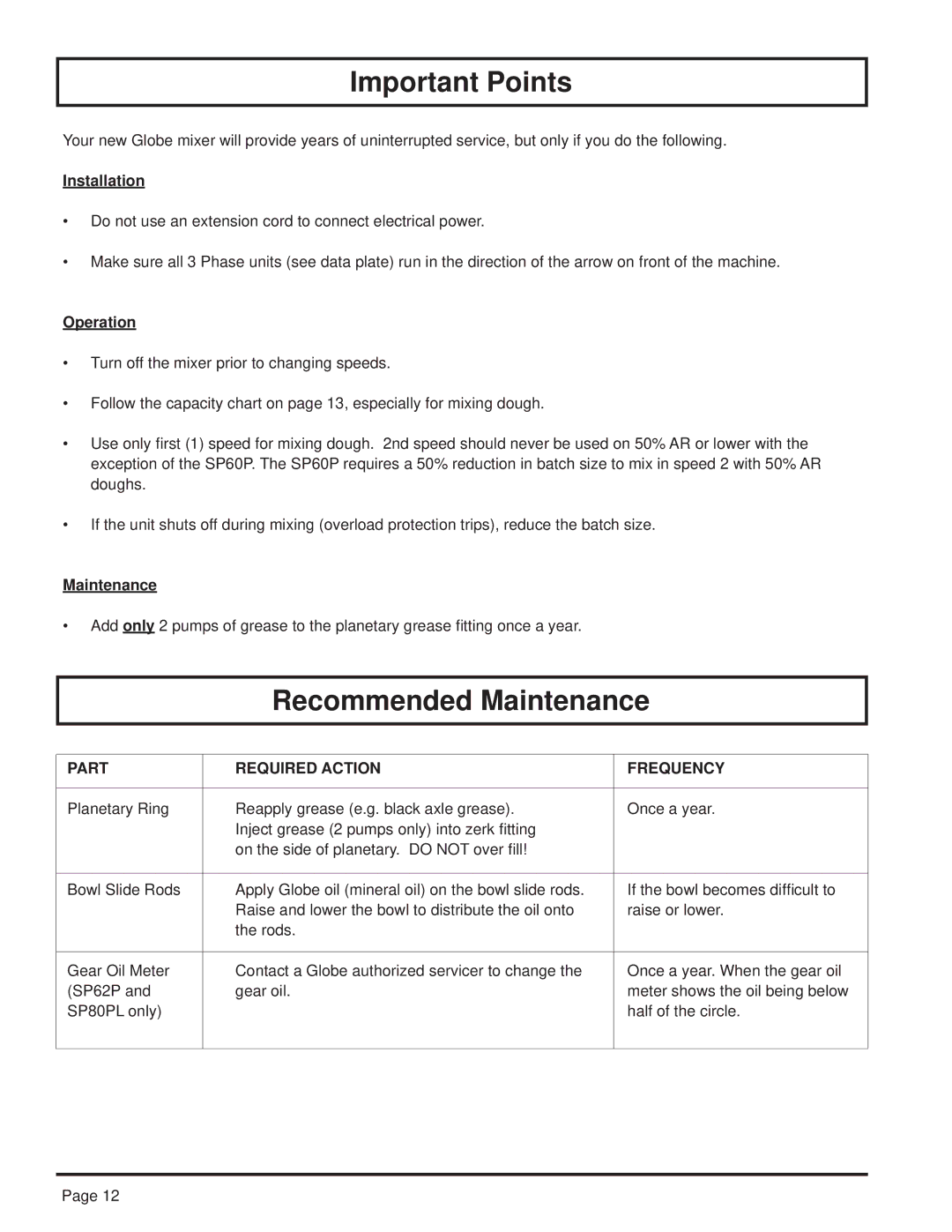

Recommended Maintenance

PART | REQUIRED ACTION | FREQUENCY |

|

|

|

Planetary Ring | Reapply grease (e.g. black axle grease). | Once a year. |

| Inject grease (2 pumps only) into zerk fitting |

|

| on the side of planetary. DO NOT over fill! |

|

|

|

|

Bowl Slide Rods | Apply Globe oil (mineral oil) on the bowl slide rods. | If the bowl becomes difficult to |

| Raise and lower the bowl to distribute the oil onto | raise or lower. |

| the rods. |

|

|

|

|

Gear Oil Meter | Contact a Globe authorized servicer to change the | Once a year. When the gear oil |

(SP62P and | gear oil. | meter shows the oil being below |

SP80PL only) |

| half of the circle. |

|

|

|

Page 12