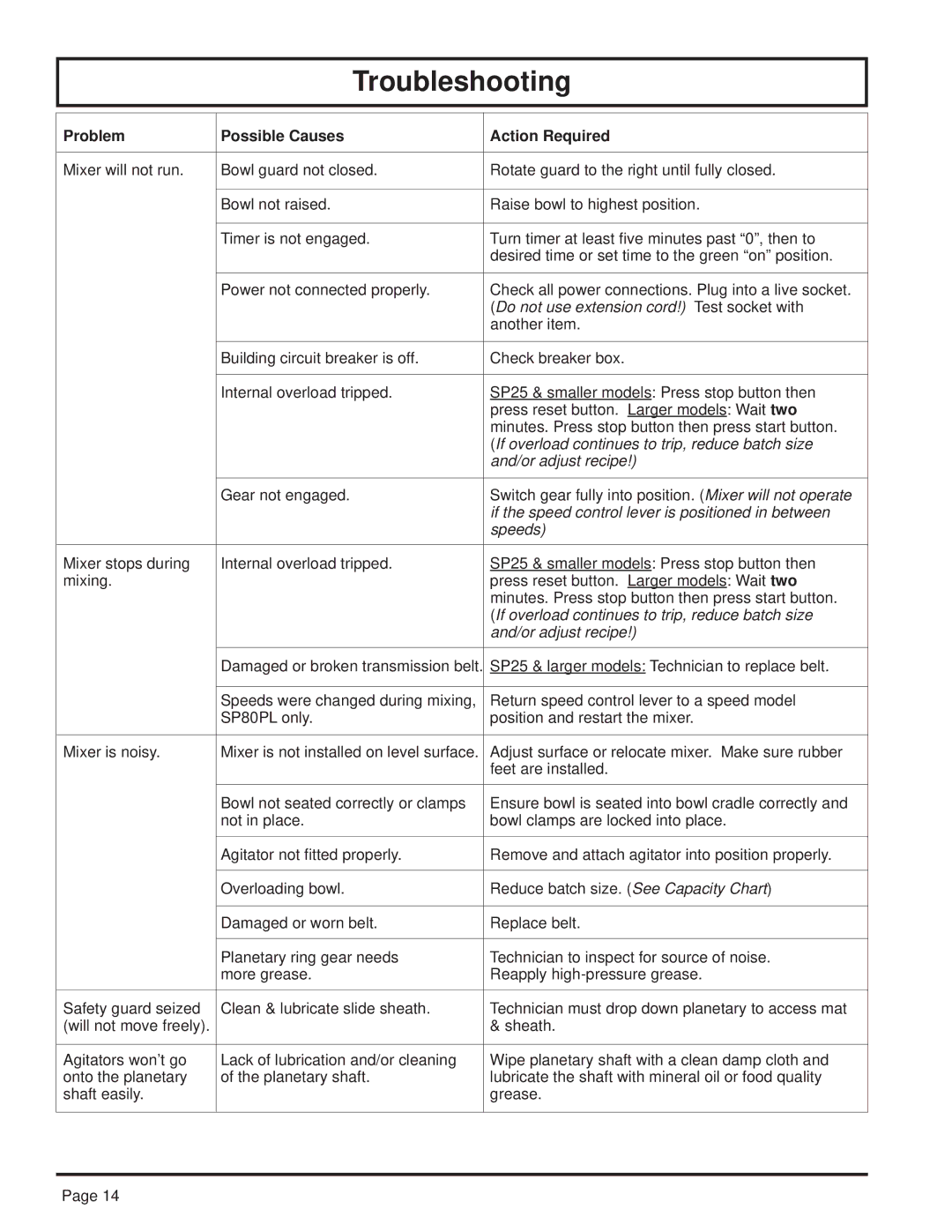

Troubleshooting

Problem | Possible Causes | Action Required |

|

|

|

Mixer will not run. | Bowl guard not closed. | Rotate guard to the right until fully closed. |

|

|

|

| Bowl not raised. | Raise bowl to highest position. |

|

|

|

| Timer is not engaged. | Turn timer at least five minutes past “0”, then to |

|

| desired time or set time to the green “on” position. |

|

|

|

| Power not connected properly. | Check all power connections. Plug into a live socket. |

|

| (Do not use extension cord!) Test socket with |

|

| another item. |

|

|

|

| Building circuit breaker is off. | Check breaker box. |

|

|

|

| Internal overload tripped. | SP25 & smaller models: Press stop button then |

|

| press reset button. Larger models: Wait two |

|

| minutes. Press stop button then press start button. |

|

| (If overload continues to trip, reduce batch size |

|

| and/or adjust recipe!) |

|

|

|

| Gear not engaged. | Switch gear fully into position. (Mixer will not operate |

|

| if the speed control lever is positioned in between |

|

| speeds) |

|

|

|

Mixer stops during | Internal overload tripped. | SP25 & smaller models: Press stop button then |

mixing. |

| press reset button. Larger models: Wait two |

|

| minutes. Press stop button then press start button. |

|

| (If overload continues to trip, reduce batch size |

|

| and/or adjust recipe!) |

|

|

|

| Damaged or broken transmission belt. | SP25 & larger models: Technician to replace belt. |

|

|

|

| Speeds were changed during mixing, | Return speed control lever to a speed model |

| SP80PL only. | position and restart the mixer. |

|

|

|

Mixer is noisy. | Mixer is not installed on level surface. | Adjust surface or relocate mixer. Make sure rubber |

|

| feet are installed. |

|

|

|

| Bowl not seated correctly or clamps | Ensure bowl is seated into bowl cradle correctly and |

| not in place. | bowl clamps are locked into place. |

|

|

|

| Agitator not fitted properly. | Remove and attach agitator into position properly. |

|

|

|

| Overloading bowl. | Reduce batch size. (See Capacity Chart) |

|

|

|

| Damaged or worn belt. | Replace belt. |

|

|

|

| Planetary ring gear needs | Technician to inspect for source of noise. |

| more grease. | Reapply |

|

|

|

Safety guard seized | Clean & lubricate slide sheath. | Technician must drop down planetary to access mat |

(will not move freely). |

| & sheath. |

|

|

|

Agitators won’t go | Lack of lubrication and/or cleaning | Wipe planetary shaft with a clean damp cloth and |

onto the planetary | of the planetary shaft. | lubricate the shaft with mineral oil or food quality |

shaft easily. |

| grease. |

|

|

|

Page 14