RT6621031r2, GMS8 33-3/8 GAS FURNACE UNITS specifications

Goodman Manufacturing is renowned for delivering reliable and efficient HVAC systems, and the RT6621031R2 GMS8 Gas Furnace is no exception. This gas furnace is specifically engineered for residential heating needs, ensuring comfort in various climates. Its design is both effective and energy-efficient, making it a popular choice among homeowners.One of the main features of the GMS8 furnace is its two-stage heating capability. This technology allows the unit to operate at two different levels of heating output, which helps maintain a more consistent temperature within the home. During milder temperatures, the furnace can operate at a lower stage, saving energy while still delivering adequate warmth. On colder days, it seamlessly transitions to the higher stage, ensuring maximum comfort.

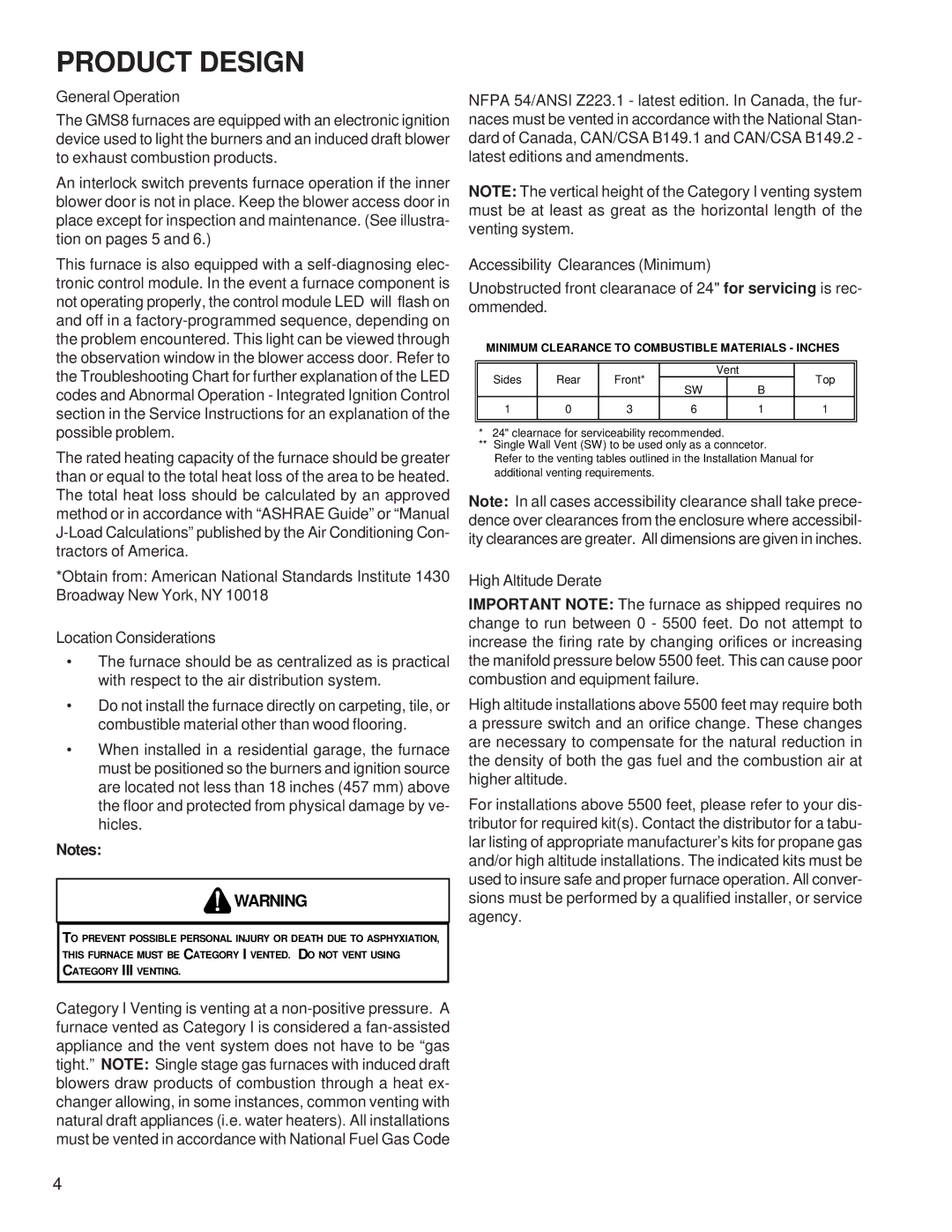

The GMS8 boasts a multi-speed blower motor, which enhances its overall efficiency and performance. This allows for variable airflow adjustments, improving air distribution throughout the home. The result is not only increased comfort but also reduced noise levels, making the operation of this furnace pleasantly quiet.

An important characteristic of the GMS8 is its durable construction, featuring a heavy-gauge steel cabinet designed to withstand harsh operating conditions. The integrated insulated blower compartment further ensures that the unit operates efficiently while minimizing heat loss. Its compact design allows for easier installation in various home configurations.

In terms of energy efficiency, the GMS8 is equipped with a 80% Annual Fuel Utilization Efficiency (AFUE) rating. This means that 80% of the gas consumed translates into usable heat, making it a cost-effective option for heating your home. Additionally, it is compatible with a range of programmable thermostats, allowing homeowners to optimize their heating schedules and further enhance energy savings.

The GMS8 furnace is also designed with safety in mind. It includes features such as an integrated self-diagnostic control board and a flame rollout switch for enhanced operational safety. The extended warranty options available also provide peace of mind, ensuring that homeowners feel secure in their investment.

In summary, the Goodman RT6621031R2 GMS8 Gas Furnace is an efficient, reliable, and durable heating solution for homes. With its two-stage heating capabilities, multi-speed blower motor, and a robust design, it stands out as a trusted choice for families seeking comfort and energy savings during the chilly months.