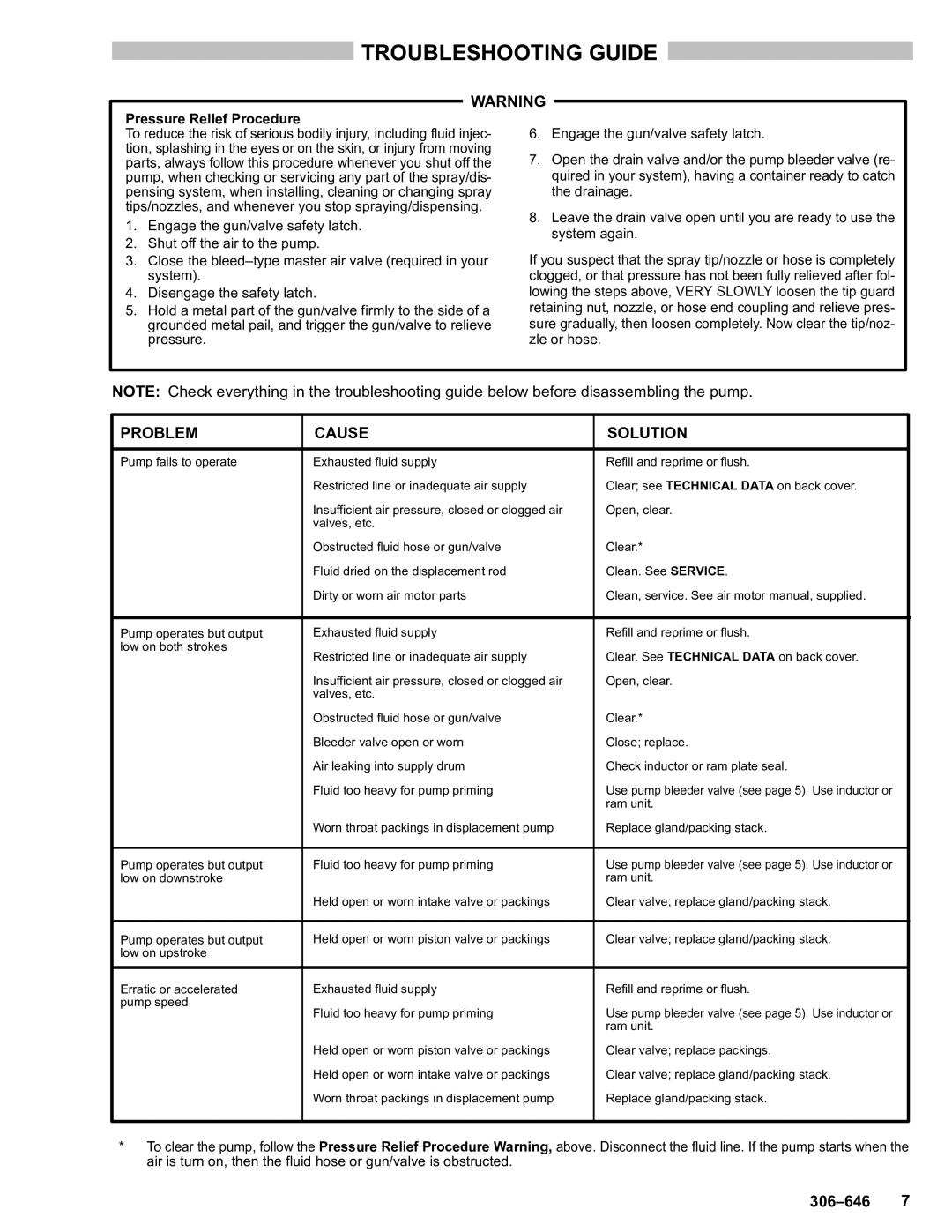

TROUBLESHOOTING GUIDE

WARNING

Pressure Relief Procedure | 6. Engage the gun/valve safety latch. | ||

To reduce the risk of serious bodily injury, including fluid injec- | |||

tion, splashing in the eyes or on the skin, or injury from moving | 7. Open the drain valve and/or the pump bleeder valve (re- | ||

parts, always follow this procedure whenever you shut off the | |||

pump, when checking or servicing any part of the spray/dis- | quired in your system), having a container ready to catch | ||

pensing system, when installing, cleaning or changing spray | the drainage. | ||

tips/nozzles, and whenever you stop spraying/dispensing. | 8. Leave the drain valve open until you are ready to use the | ||

1. | Engage the gun/valve safety latch. | ||

system again. | |||

2. | Shut off the air to the pump. | ||

If you suspect that the spray tip/nozzle or hose is completely | |||

3. | Close the | ||

| system). | clogged, or that pressure has not been fully relieved after fol- | |

4. | Disengage the safety latch. | lowing the steps above, VERY SLOWLY loosen the tip guard | |

5. | Hold a metal part of the gun/valve firmly to the side of a | retaining nut, nozzle, or hose end coupling and relieve pres- | |

| grounded metal pail, and trigger the gun/valve to relieve | sure gradually, then loosen completely. Now clear the tip/noz- | |

| pressure. | zle or hose. | |

NOTE: Check everything in the troubleshooting guide below before disassembling the pump.

PROBLEM | CAUSE | SOLUTION |

|

|

|

Pump fails to operate | Exhausted fluid supply | Refill and reprime or flush. |

| Restricted line or inadequate air supply | Clear; see TECHNICAL DATA on back cover. |

| Insufficient air pressure, closed or clogged air | Open, clear. |

| valves, etc. |

|

| Obstructed fluid hose or gun/valve | Clear.* |

| Fluid dried on the displacement rod | Clean. See SERVICE. |

| Dirty or worn air motor parts | Clean, service. See air motor manual, supplied. |

|

|

|

Pump operates but output | Exhausted fluid supply | Refill and reprime or flush. |

low on both strokes | Restricted line or inadequate air supply | Clear. See TECHNICAL DATA on back cover. |

| ||

| Insufficient air pressure, closed or clogged air | Open, clear. |

| valves, etc. |

|

| Obstructed fluid hose or gun/valve | Clear.* |

| Bleeder valve open or worn | Close; replace. |

| Air leaking into supply drum | Check inductor or ram plate seal. |

| Fluid too heavy for pump priming | Use pump bleeder valve (see page 5). Use inductor or |

|

| ram unit. |

| Worn throat packings in displacement pump | Replace gland/packing stack. |

|

|

|

Pump operates but output | Fluid too heavy for pump priming | Use pump bleeder valve (see page 5). Use inductor or |

low on downstroke |

| ram unit. |

| Held open or worn intake valve or packings | Clear valve; replace gland/packing stack. |

|

|

|

Pump operates but output | Held open or worn piston valve or packings | Clear valve; replace gland/packing stack. |

low on upstroke |

|

|

|

|

|

Erratic or accelerated | Exhausted fluid supply | Refill and reprime or flush. |

pump speed | Fluid too heavy for pump priming | Use pump bleeder valve (see page 5). Use inductor or |

| ||

|

| ram unit. |

| Held open or worn piston valve or packings | Clear valve; replace packings. |

| Held open or worn intake valve or packings | Clear valve; replace gland/packing stack. |

| Worn throat packings in displacement pump | Replace gland/packing stack. |

|

|

|

*To clear the pump, follow the Pressure Relief Procedure Warning, above. Disconnect the fluid line. If the pump starts when the air is turn on, then the fluid hose or gun/valve is obstructed.