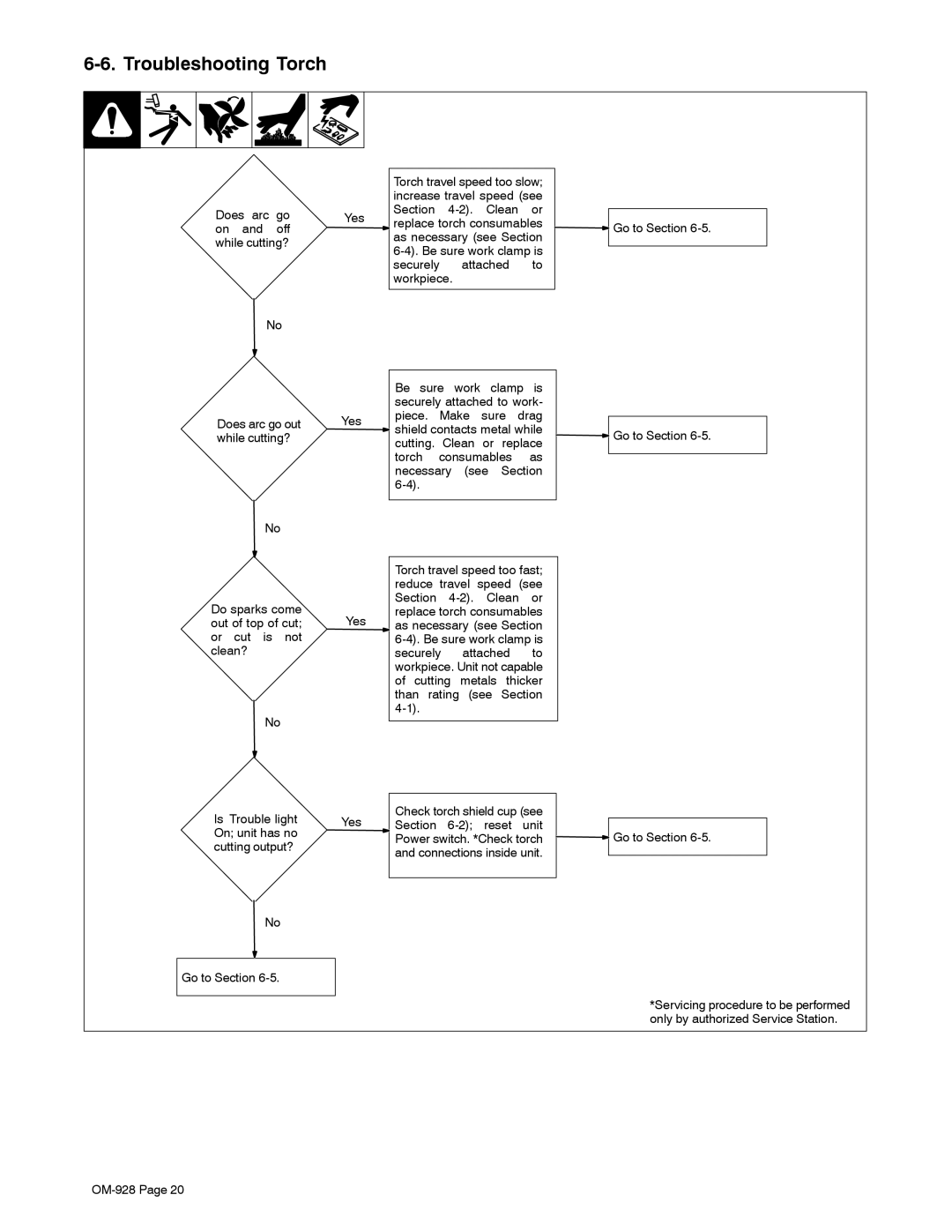

6-6. Troubleshooting Torch

Does arc go on and off while cutting?

No

| Torch travel speed too slow; |

| |||

| increase travel speed (see |

| |||

Yes | Section |

| |||

| |||||

replace torch consumables | Go to Section | ||||

| |||||

| as necessary (see Section | ||||

|

| ||||

|

| ||||

|

| ||||

| securely | attached | to |

| |

| workpiece. |

|

|

| |

Does arc go out while cutting?

No

Do sparks come out of top of cut; or cut is not clean?

No

Is Trouble light On; unit has no cutting output?

No

Go to Section

Yes

Yes

Yes

Be sure work clamp is securely attached to work- piece. Make sure drag ![]() shield contacts metal while cutting. Clean or replace torch consumables as necessary (see Section

shield contacts metal while cutting. Clean or replace torch consumables as necessary (see Section

Torch travel speed too fast; reduce travel speed (see Section

Check torch shield cup (see Section

![]() Go to Section

Go to Section

![]() Go to Section

Go to Section

*Servicing procedure to be performed only by authorized Service Station.