Maintenance

Maintenance

Clean Dispensing Valve and System Daily

NOTICE

Be sure that the solvent you use is compatible with the fluid being dispensed to avoid clogging the fluid pas- sages in the valve.

An important part of the care and maintenance of your automatic dispensing valve is proper flushing. Flush the valve daily with a compatible solvent until all traces of fluid are removed from the valve passages. Perform Pressure Relief Procedure, page 5 before flushing.

Clean the outside surfaces of the valve by wiping with a soft cloth dampened with a compatible solvent.

NOTICE

Never immerse the entire dispensing valve in solvent. Immersing in solvent removes lubricants and can damage packings.

To remove a hardened particle from the orifice, blow air through the orifice from the front.

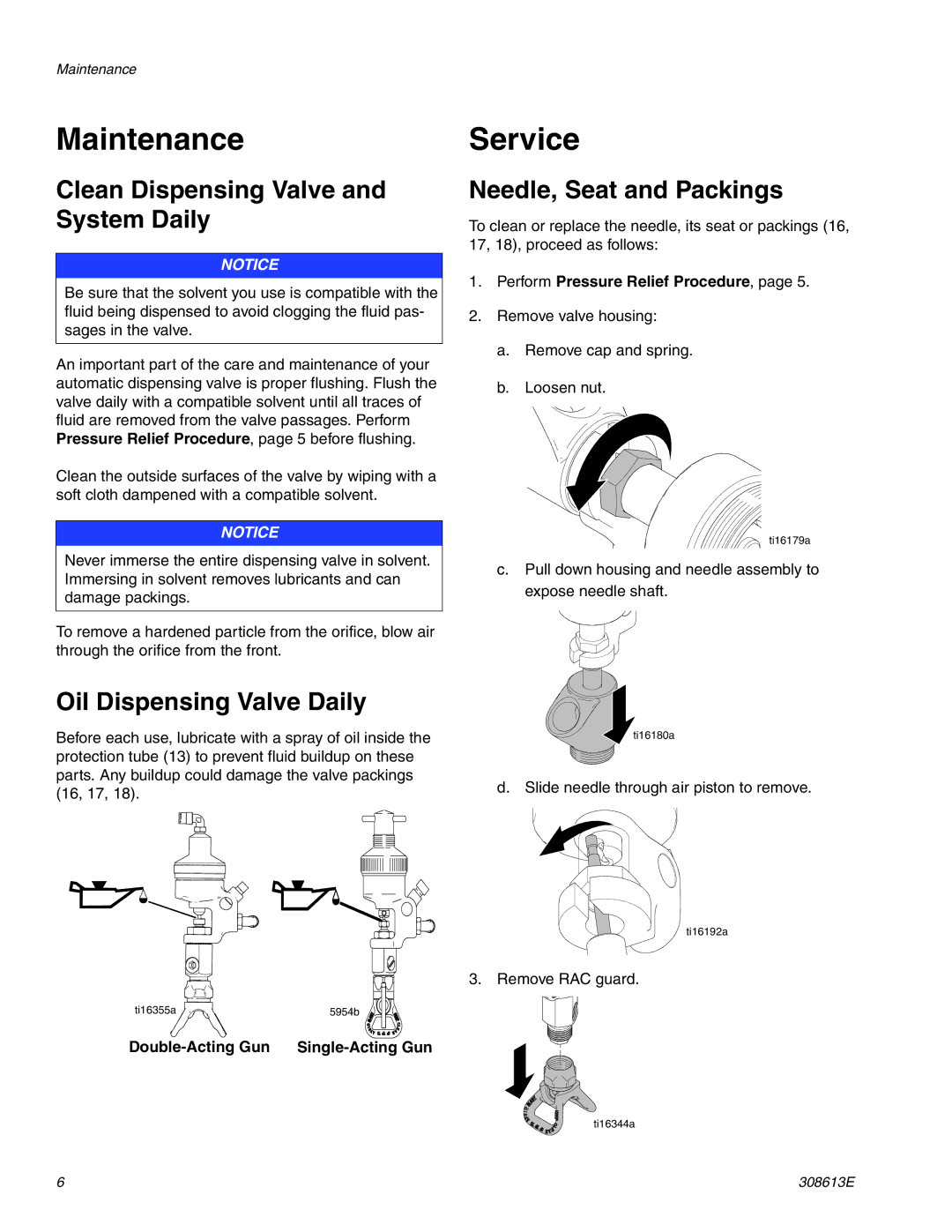

Oil Dispensing Valve Daily

Before each use, lubricate with a spray of oil inside the protection tube (13) to prevent fluid buildup on these parts. Any buildup could damage the valve packings (16, 17, 18).

ti16355a | 5954b |

Service

Needle, Seat and Packings

To clean or replace the needle, its seat or packings (16, 17, 18), proceed as follows:

1.Perform Pressure Relief Procedure, page 5.

2.Remove valve housing:

a.Remove cap and spring.

b.Loosen nut.

ti16179a

c.Pull down housing and needle assembly to expose needle shaft.

ti16180a

d. Slide needle through air piston to remove.

ti16192a

3. Remove RAC guard.

ti16344a

6 | 308613E |