Service

Replacing the Fluid Diaphragms

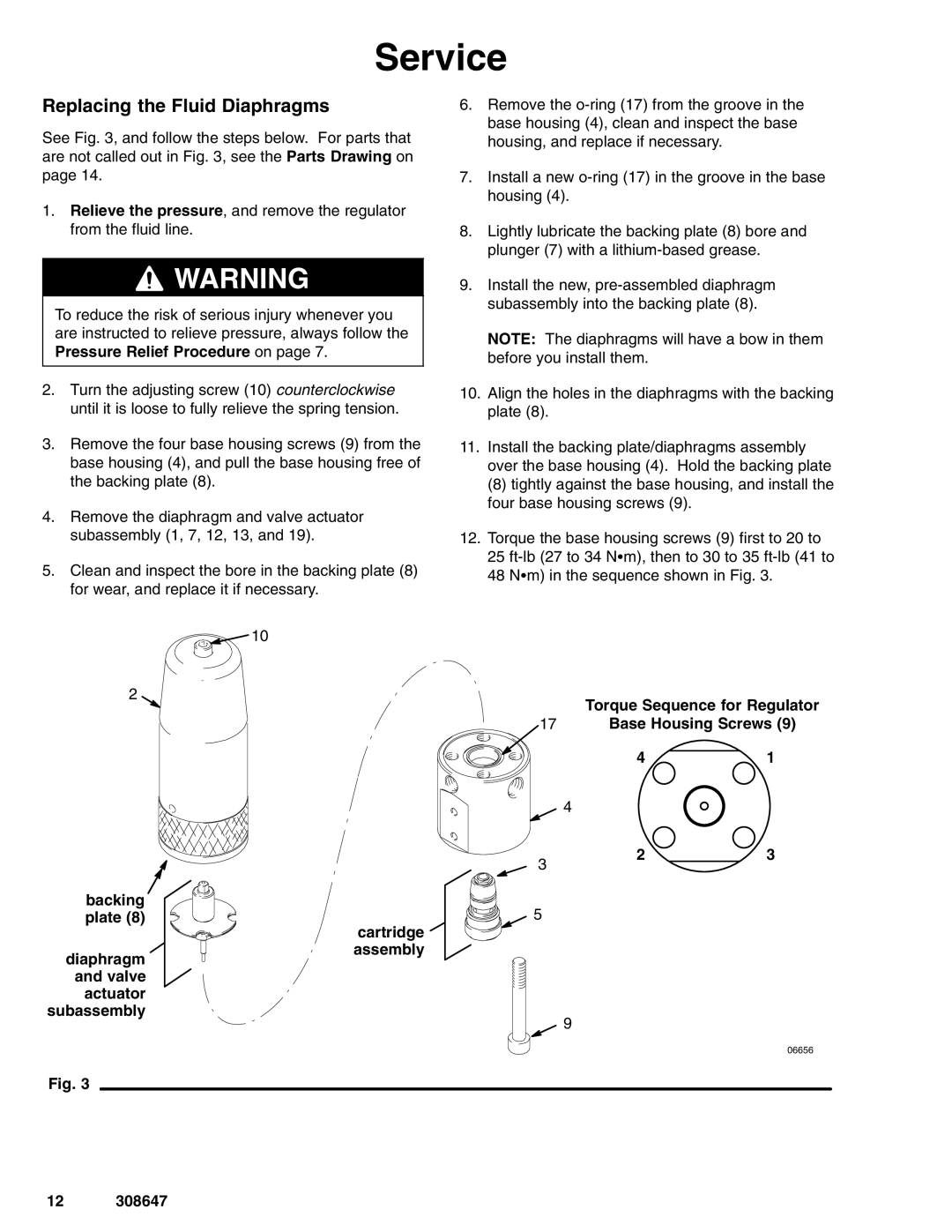

See Fig. 3, and follow the steps below. For parts that are not called out in Fig. 3, see the Parts Drawing on page 14.

1.Relieve the pressure, and remove the regulator from the fluid line.

![]() WARNING

WARNING

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the Pressure Relief Procedure on page 7.

2.Turn the adjusting screw (10) counterclockwise until it is loose to fully relieve the spring tension.

3.Remove the four base housing screws (9) from the base housing (4), and pull the base housing free of the backing plate (8).

4.Remove the diaphragm and valve actuator subassembly (1, 7, 12, 13, and 19).

5.Clean and inspect the bore in the backing plate (8) for wear, and replace it if necessary.

![]() 10

10

6.Remove the

7.Install a new

8.Lightly lubricate the backing plate (8) bore and plunger (7) with a

9.Install the new,

NOTE: The diaphragms will have a bow in them before you install them.

10.Align the holes in the diaphragms with the backing plate (8).

11.Install the backing plate/diaphragms assembly over the base housing (4). Hold the backing plate

(8)tightly against the base housing, and install the four base housing screws (9).

12.Torque the base housing screws (9) first to 20 to 25

2

Torque Sequence for Regulator

17Base Housing Screws (9)

41

4

backing plate (8)

diaphragm and valve actuator subassembly

cartridge assembly

3

5

23

Fig. 3

9

06656

12 308647