Installation

Grounding the System

![]() WARNING

WARNING

FIRE AND EXPLOSION HAZARD Before operating the fluid pressure regulator, ground the system as explained below.

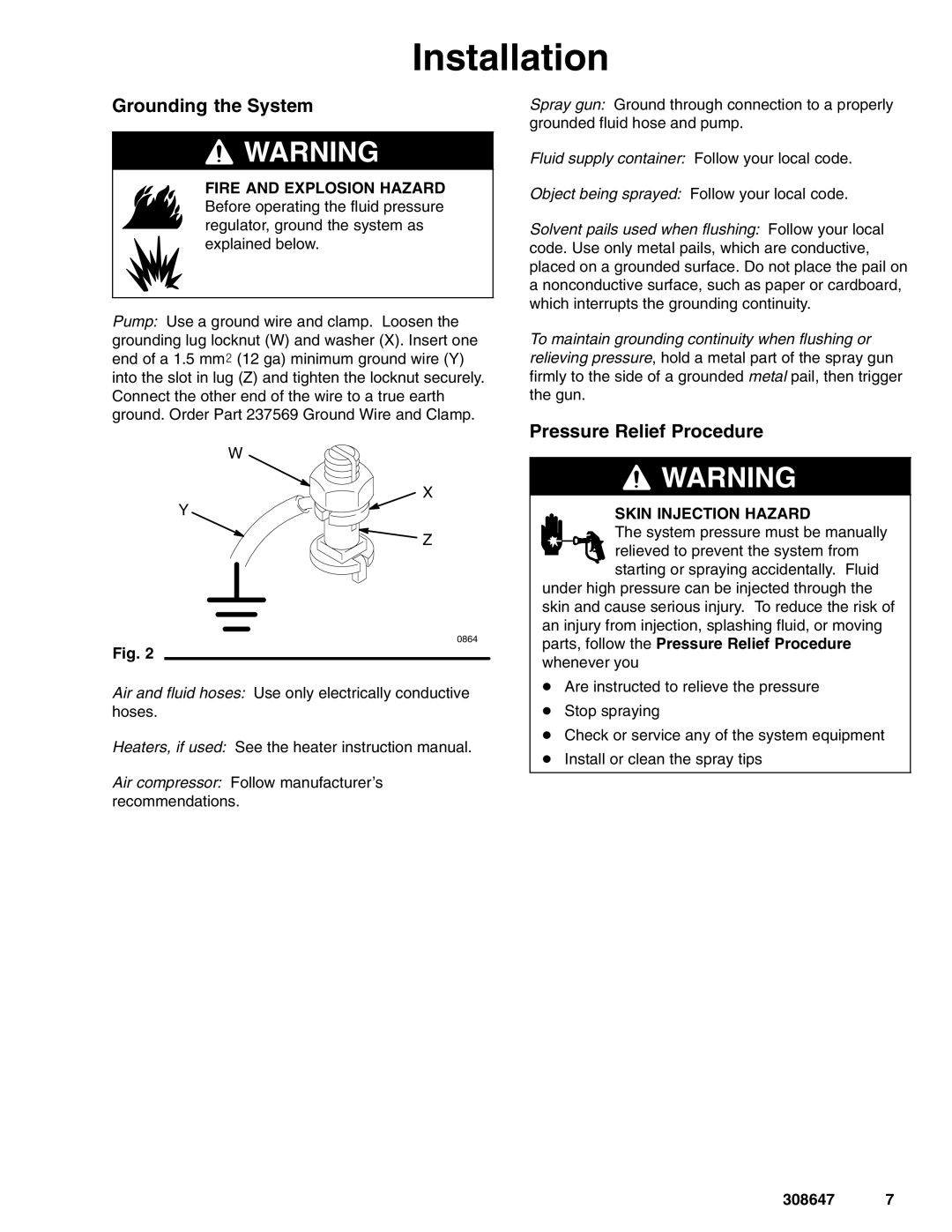

Pump: Use a ground wire and clamp. Loosen the grounding lug locknut (W) and washer (X). Insert one end of a 1.5 mm@ (12 ga) minimum ground wire (Y) into the slot in lug (Z) and tighten the locknut securely. Connect the other end of the wire to a true earth ground. Order Part 237569 Ground Wire and Clamp.

W

X

Y

Z

0864

Fig. 2

Air and fluid hoses: Use only electrically conductive hoses.

Heaters, if used: See the heater instruction manual.

Air compressor: Follow manufacturer’s recommendations.

Spray gun: Ground through connection to a properly grounded fluid hose and pump.

Fluid supply container: Follow your local code.

Object being sprayed: Follow your local code.

Solvent pails used when flushing: Follow your local code. Use only metal pails, which are conductive, placed on a grounded surface. Do not place the pail on a nonconductive surface, such as paper or cardboard, which interrupts the grounding continuity.

To maintain grounding continuity when flushing or relieving pressure, hold a metal part of the spray gun firmly to the side of a grounded metal pail, then trigger the gun.

Pressure Relief Procedure

![]() WARNING

WARNING

SKIN INJECTION HAZARD

The system pressure must be manually relieved to prevent the system from starting or spraying accidentally. Fluid

under high pressure can be injected through the skin and cause serious injury. To reduce the risk of an injury from injection, splashing fluid, or moving parts, follow the Pressure Relief Procedure whenever you

DAre instructed to relieve the pressure

DStop spraying

DCheck or service any of the system equipment

DInstall or clean the spray tips