Instructions

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever you see this symbol.

Disassembly

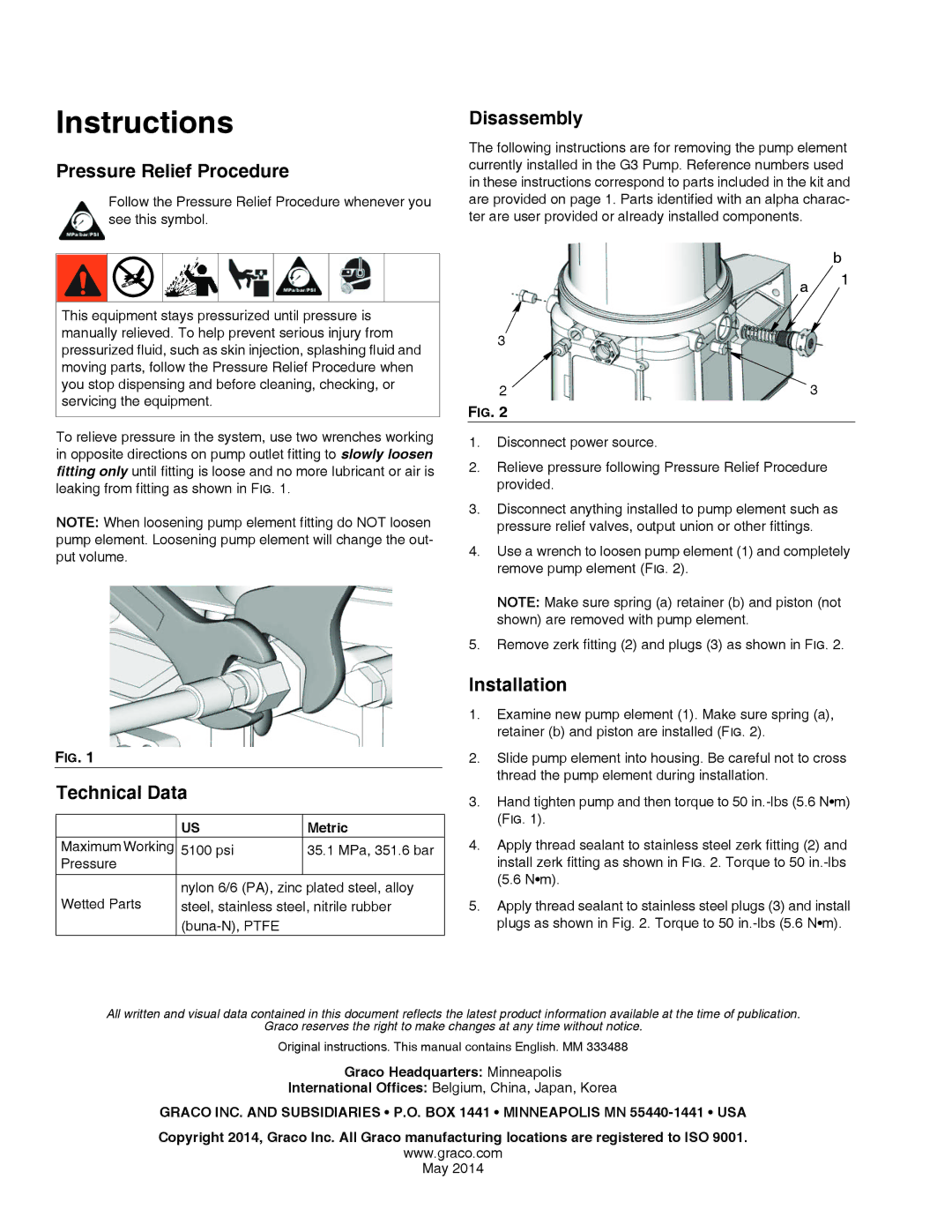

The following instructions are for removing the pump element currently installed in the G3 Pump. Reference numbers used in these instructions correspond to parts included in the kit and are provided on page 1. Parts identified with an alpha charac- ter are user provided or already installed components.

This equipment stays pressurized until pressure is manually relieved. To help prevent serious injury from pressurized fluid, such as skin injection, splashing fluid and moving parts, follow the Pressure Relief Procedure when you stop dispensing and before cleaning, checking, or servicing the equipment.

To relieve pressure in the system, use two wrenches working in opposite directions on pump outlet fitting to slowly loosen fitting only until fitting is loose and no more lubricant or air is leaking from fitting as shown in FIG. 1.

NOTE: When loosening pump element fitting do NOT loosen pump element. Loosening pump element will change the out- put volume.

FIG. 1

Technical Data

| US | Metric |

Maximum Working | 5100 psi | 35.1 MPa, 351.6 bar |

Pressure |

|

|

Wetted Parts | nylon 6/6 (PA), zinc plated steel, alloy | |

steel, stainless steel, nitrile rubber | ||

|

| |

b a 1

3

2 | 3 |

FIG. 2

1.Disconnect power source.

2.Relieve pressure following Pressure Relief Procedure provided.

3.Disconnect anything installed to pump element such as pressure relief valves, output union or other fittings.

4.Use a wrench to loosen pump element (1) and completely remove pump element (FIG. 2).

NOTE: Make sure spring (a) retainer (b) and piston (not shown) are removed with pump element.

5.Remove zerk fitting (2) and plugs (3) as shown in FIG. 2.

Installation

1.Examine new pump element (1). Make sure spring (a), retainer (b) and piston are installed (FIG. 2).

2.Slide pump element into housing. Be careful not to cross thread the pump element during installation.

3.Hand tighten pump and then torque to 50

4.Apply thread sealant to stainless steel zerk fitting (2) and install zerk fitting as shown in FIG. 2. Torque to 50

5.Apply thread sealant to stainless steel plugs (3) and install plugs as shown in Fig. 2. Torque to 50

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 333488

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN

www.graco.com

May 2014