Installation

Air Exhaust Ventilation

![]() WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Be sure to read and follow the warnings and precautions regarding TOXIC FLUID HAZARD, and FIRE OR EXPLO- SION HAZARD on page 4, before op- erating this pump.

Be sure the system is properly ventilated for your type of installation. You must vent the exhaust to a safe place, away from people, animals, food handl- ing areas, and all sources of ignition when pumping flammable or hazardous fluids.

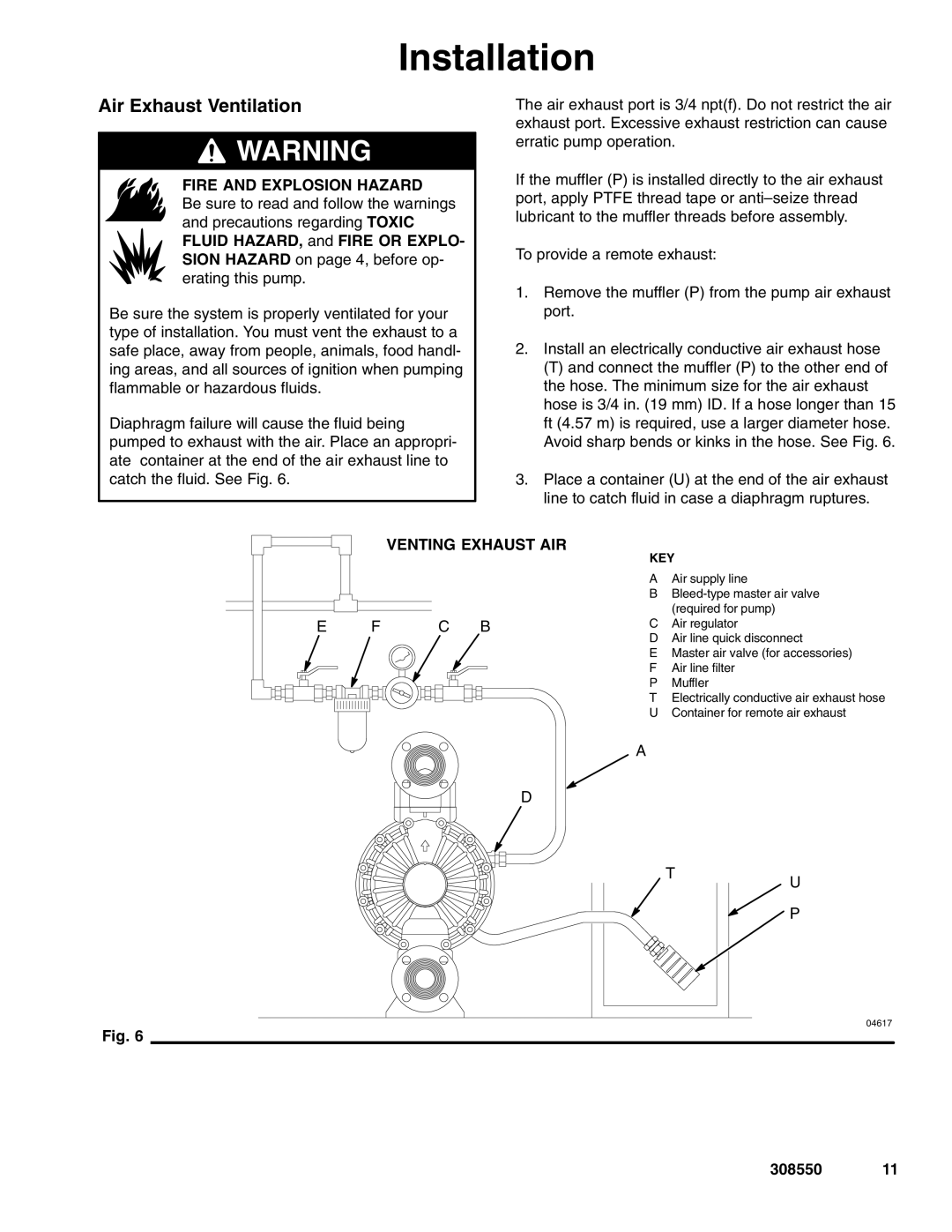

Diaphragm failure will cause the fluid being pumped to exhaust with the air. Place an appropri- ate container at the end of the air exhaust line to catch the fluid. See Fig. 6.

The air exhaust port is 3/4 npt(f). Do not restrict the air exhaust port. Excessive exhaust restriction can cause erratic pump operation.

If the muffler (P) is installed directly to the air exhaust port, apply PTFE thread tape or

To provide a remote exhaust:

1.Remove the muffler (P) from the pump air exhaust port.

2.Install an electrically conductive air exhaust hose

(T) and connect the muffler (P) to the other end of the hose. The minimum size for the air exhaust hose is 3/4 in. (19 mm) ID. If a hose longer than 15 ft (4.57 m) is required, use a larger diameter hose. Avoid sharp bends or kinks in the hose. See Fig. 6.

3.Place a container (U) at the end of the air exhaust line to catch fluid in case a diaphragm ruptures.

VENTING EXHAUST AIR

E F C B

KEY

AAir supply line

B

CAir regulator

DAir line quick disconnect

EMaster air valve (for accessories)

FAir line filter

P Muffler

TElectrically conductive air exhaust hose

UContainer for remote air exhaust

A

D

T

Fig. 6

U

P

04617

308550 11