Flushing

•Flush before changing colors, before storing, and before repairing equipment.

•Flush at the lowest pressure possible. Check con- nectors for leaks and tighten as necessary.

•Flush with a fluid that is compatible with the fluid being dispensed and the equipment wetted parts.

1.Follow Pressure Relief Procedure, page 14.

2.Supply the appropriate flushing material to the sys- tem.

3.Set pump to lowest possible fluid pressure, and start the pump.

4.Flush long enough to thoroughly clean the system.

5.Follow Pressure Relief Procedure, page 14.

Changing the TSL

Check the condition of the TSL and the level in the res- ervoir every week, minimum. TSL should be changed at least every month.

Part No. 206995 Throat Seal Liquid (TSL) carries resi- due from the pump rod into the reservoir. Discoloration of the TSL fluid is to be expected during normal opera- tion. After some time the TSL will thicken and darken, and must be replaced. Thick, dirty TSL will not pump through the lines and will harden in the pump

Maintenance

How long TSL lasts depends on which chemicals are used, how much is used, what pressure, and condition of the pump seal and rod.

A drop in the level of TSL in the reservoir indicates that the throat packings are starting to wear. Add TSL to the reservoir and keep the level above the Minimum fill line. Monitor the usage and condition of the TSL. If pumped material bypasses the throat packings and enters the TSL reservoir, replace the packings.

To change the TSL:

1. Shut off the pump.

To avoid the buildup of static charge, do not rub the plastic bottle with a dry cloth while it is attached to the pump. Remove the bottle to clean, if needed.

2.Remove and empty the reservoir bottle. Clean any residue.

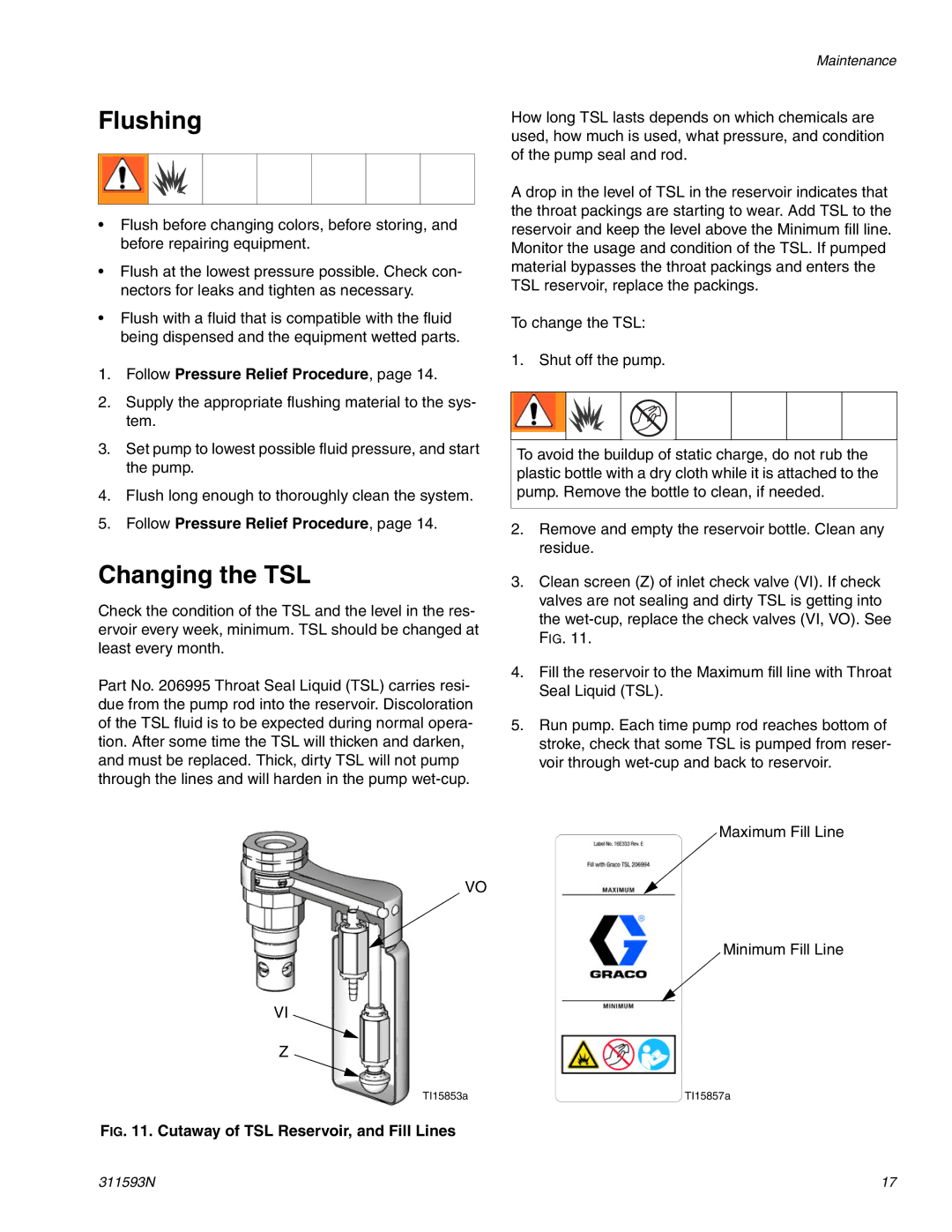

3.Clean screen (Z) of inlet check valve (VI). If check valves are not sealing and dirty TSL is getting into the

4.Fill the reservoir to the Maximum fill line with Throat Seal Liquid (TSL).

5.Run pump. Each time pump rod reaches bottom of stroke, check that some TSL is pumped from reser- voir through

Maximum Fill Line

VO

Minimum Fill Line

VI

Z

TI15853a | TI15857a |

FIG. 11. Cutaway of TSL Reservoir, and Fill Lines

311593N | 17 |