Ripping

Ripping Set-up Procedure

Follow these steps before ripping.

These steps must be repeated each time a different thickness workpiece is ripped. A kerf must be made for each different width cut. Also see the special notes for bevel

1.Prepare table:

-insert solid (no kerfs) fence (Note: Use auxiliary fence when blade is set 1/2 to 2" from fence (See Cutting Aides)

-tighten table clamps.

2.Prepare blade:

-lock radial arm at 0° miter - lock blade in

-lower blade to just clear table

-lock blade carriage desired distance from fence. Note: Make sure wider part of workpiece will be between blade and fence.

*use out-rip position for rips 16" or wider

3.Make kerf:

a)turn saw on

b)lower blade about 1/16" into table

c)turn saw off and remove yellow key.

4.Place workpiece parallel to and up

against blade.** Note: Workpiece will be between blade and table front.

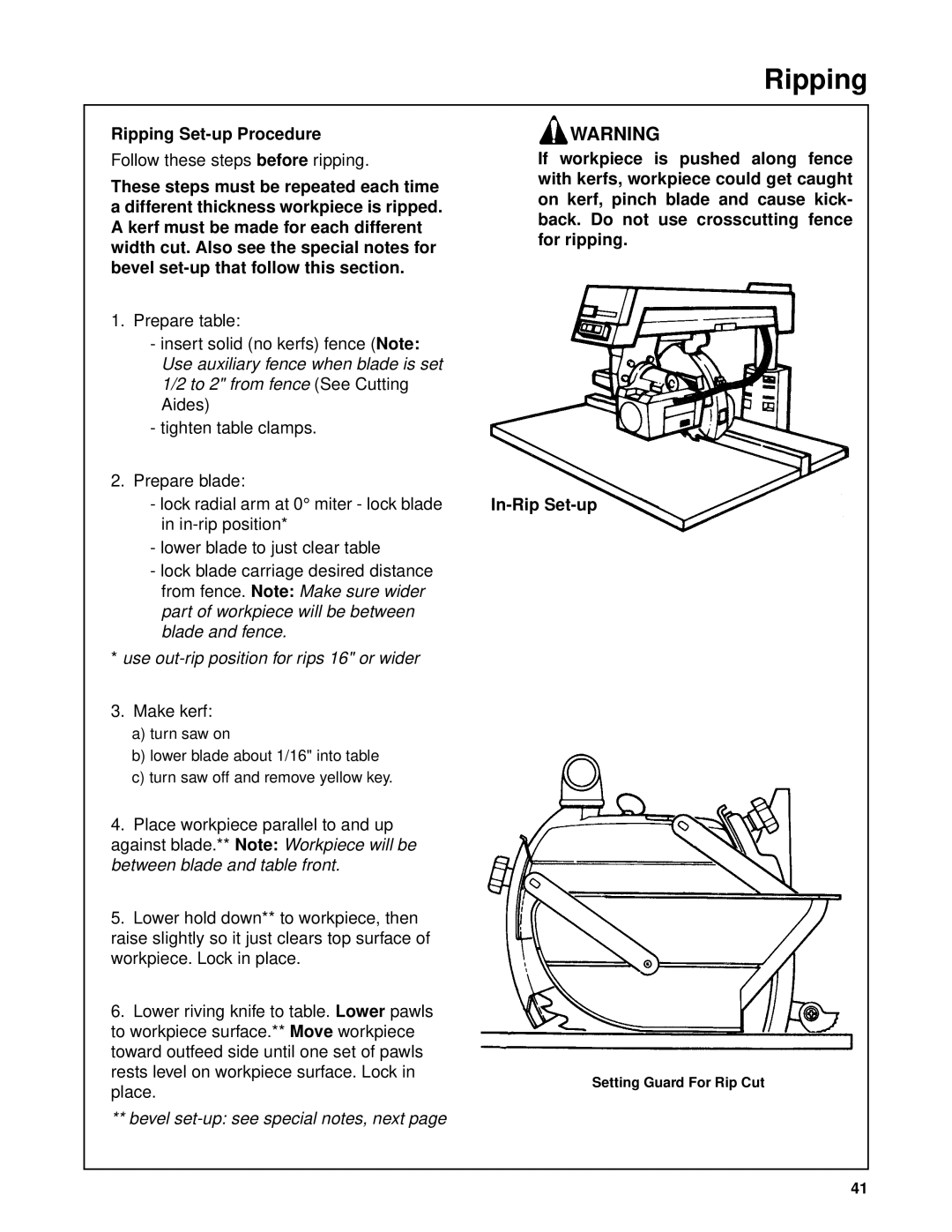

5.Lower hold down** to workpiece, then raise slightly so it just clears top surface of workpiece. Lock in place.

6.Lower riving knife to table. Lower pawls to workpiece surface.** Move workpiece toward outfeed side until one set of pawls rests level on workpiece surface. Lock in place.

** bevel

![]() WARNING

WARNING

If workpiece is pushed along fence with kerfs, workpiece could get caught on kerf, pinch blade and cause kick- back. Do not use crosscutting fence for ripping.

Setting Guard For Rip Cut

41