Repair

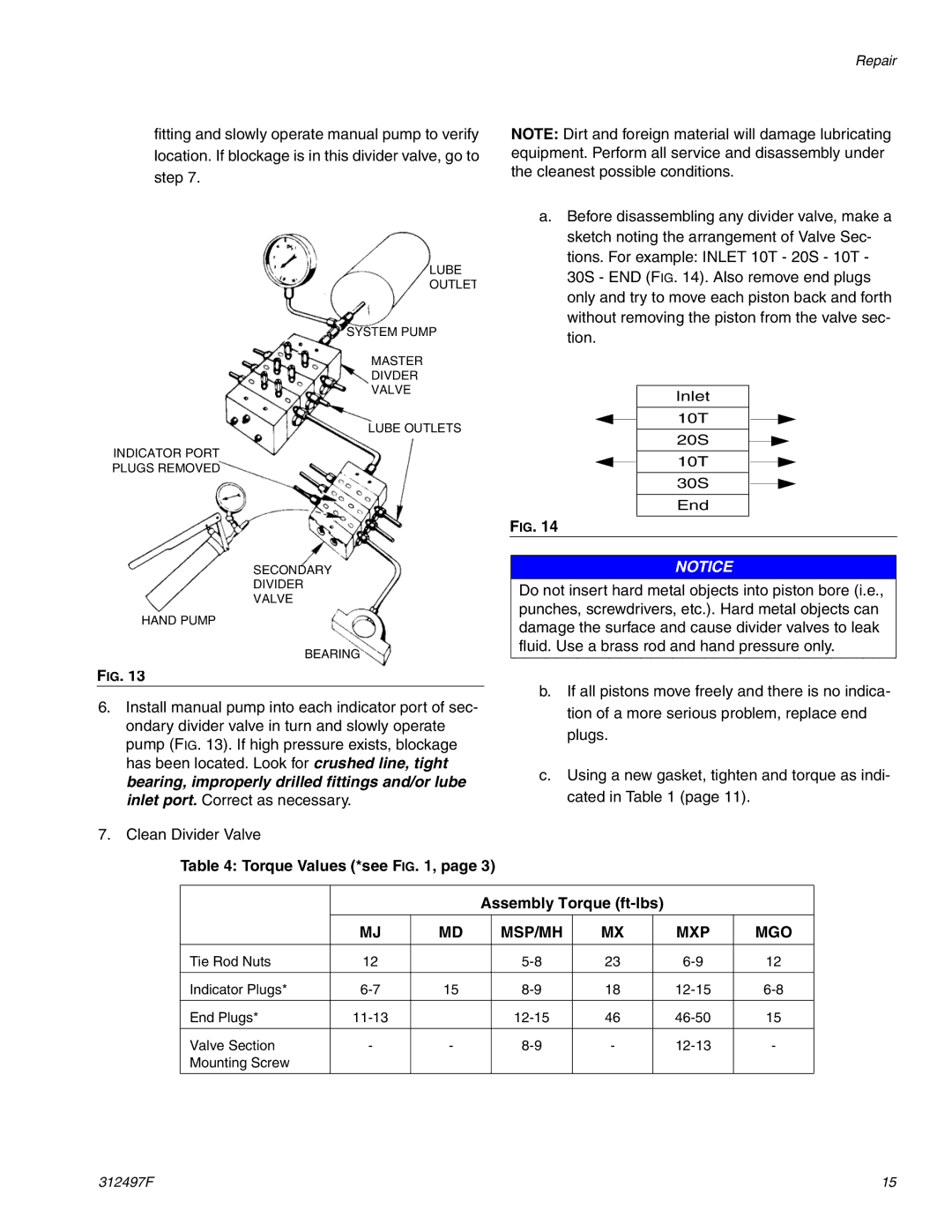

fitting and slowly operate manual pump to verify location. If blockage is in this divider valve, go to step 7.

LUBE

OUTLET

SYSTEM PUMP

MASTER

DIVDER

VALVE

LUBE OUTLETS

INDICATOR PORT

PLUGS REMOVED

SECONDARY

DIVIDER

VALVE

HAND PUMP

BEARING

FIG. 13

6.Install manual pump into each indicator port of sec- ondary divider valve in turn and slowly operate pump (FIG. 13). If high pressure exists, blockage has been located. Look for crushed line, tight bearing, improperly drilled fittings and/or lube inlet port. Correct as necessary.

7.Clean Divider Valve

NOTE: Dirt and foreign material will damage lubricating equipment. Perform all service and disassembly under the cleanest possible conditions.

a.Before disassembling any divider valve, make a sketch noting the arrangement of Valve Sec- tions. For example: INLET 10T - 20S - 10T - 30S - END (FIG. 14). Also remove end plugs only and try to move each piston back and forth without removing the piston from the valve sec- tion.

Inlet

10T

20S

10T

30S

End

FIG. 14

NOTICE

Do not insert hard metal objects into piston bore (i.e., punches, screwdrivers, etc.). Hard metal objects can damage the surface and cause divider valves to leak fluid. Use a brass rod and hand pressure only.

b.If all pistons move freely and there is no indica- tion of a more serious problem, replace end plugs.

c.Using a new gasket, tighten and torque as indi- cated in Table 1 (page 11).

Table 4: Torque Values (*see FIG. 1, page 3)

|

|

| Assembly Torque |

|

| |||

|

|

|

|

|

|

|

|

|

| MJ | MD |

| MSP/MH | MX |

| MXP | MGO |

|

|

|

|

|

|

|

|

|

Tie Rod Nuts | 12 |

|

| 23 |

| 12 | ||

|

|

|

|

|

|

|

|

|

Indicator Plugs* | 15 |

| 18 |

| ||||

|

|

|

|

|

|

|

|

|

End Plugs* |

|

| 46 |

| 15 | |||

|

|

|

|

|

|

|

|

|

Valve Section | - | - |

| - |

| - | ||

Mounting Screw |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

312497F | 15 |