Setup

The divider valve is shipped ready to install in your sys- tem. It has been

NOTICE

Do not install a divider valve into a system rated for more than the valve’s maximum operating pressure. This type of installation could result in

To install the divider valve in your system:

1.Determine an appropriate, remote mounting loca- tion.

2.Install a rupture to atmosphere fitting with a

3.Install an analog pressure gauge at the inlet to the divider valve.

4.Install a slow or no cycle shutdown in one of the pis- ton enclosure plugs. Program it to shut down after no more than 180 seconds without a complete cycle.

5.Torque. See Table 4 on page 15.

As long as lubricant is supplied under pressure to the inlet section of the divider assembly, valves sections will continue to operate in a progressive manner. Divider assemblies always follow a constant discharge pattern. Whenever lubricant flow ceases, the valving pistons will stop. When flow resumes, it will start again at the same point in the discharge cycle.

Setup

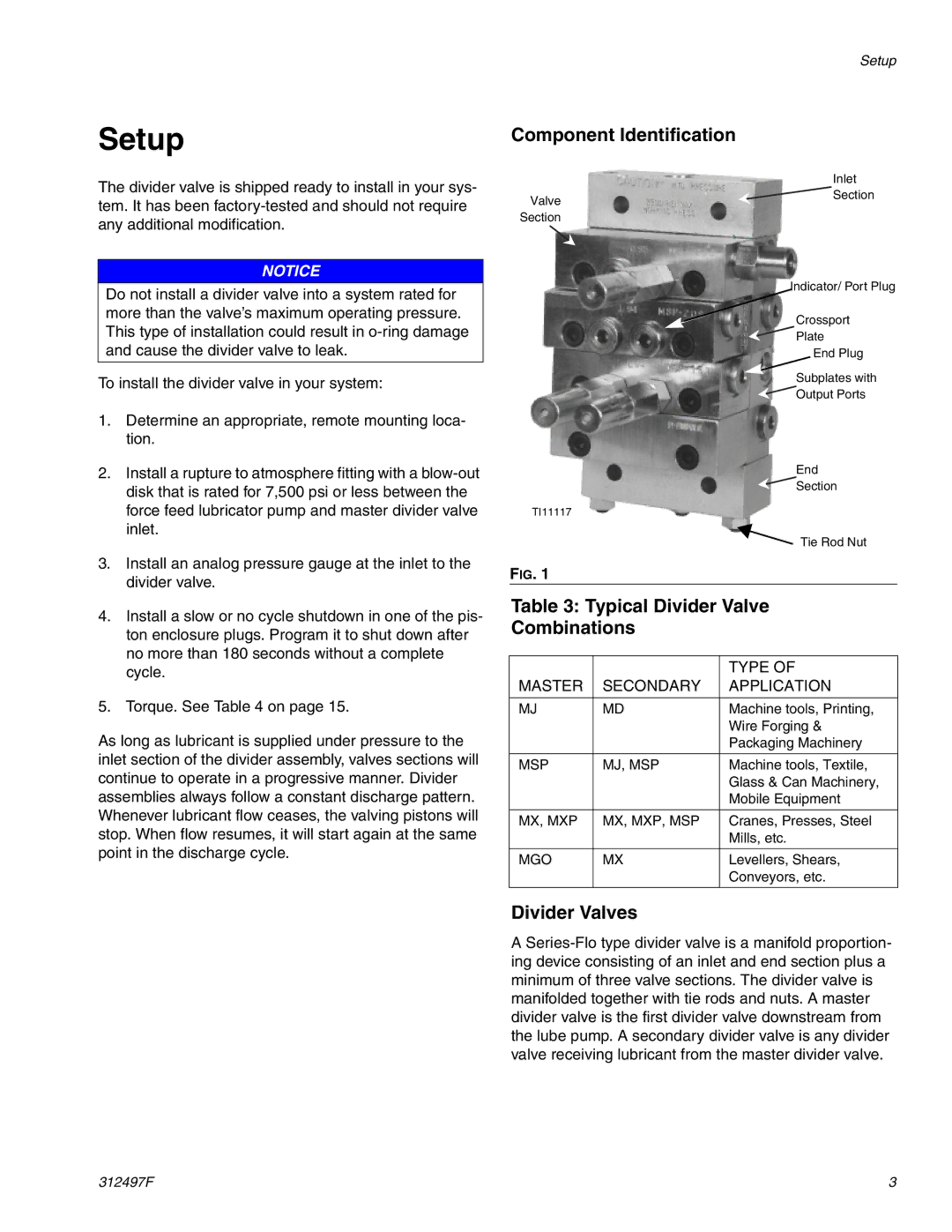

Component Identification

| Inlet |

Valve | Section |

| |

Section |

|

| Indicator/ Port Plug |

| Crossport |

| Plate |

| End Plug |

| Subplates with |

| Output Ports |

End

Section

TI11117

Tie Rod Nut

FIG. 1

Table 3: Typical Divider Valve

Combinations

|

| TYPE OF |

MASTER | SECONDARY | APPLICATION |

|

|

|

MJ | MD | Machine tools, Printing, |

|

| Wire Forging & |

|

| Packaging Machinery |

|

|

|

MSP | MJ, MSP | Machine tools, Textile, |

|

| Glass & Can Machinery, |

|

| Mobile Equipment |

|

|

|

MX, MXP | MX, MXP, MSP | Cranes, Presses, Steel |

|

| Mills, etc. |

|

|

|

MGO | MX | Levellers, Shears, |

|

| Conveyors, etc. |

|

|

|

Divider Valves

A

312497F | 3 |