How the Air-Assisted Spray Gun Operates

The

The

The spray gun has a

Spray Pattern Adjustment

To reduce the risk of component rupture and serious injury, including injection, do not exceed the gun’s maxi- mum fluid working pressure or the maximum working pressure of the lowest rated component in the system.

1.Do not turn on the gun air supply yet. Set the fluid pressure at a low starting pressure. If a fluid pres- sure regulator is installed, use it to make adjust- ments.

If your system does not have a fluid regulator, the fluid pressure is controlled by the air regulator sup- plying the pump, per the formula below:

Pump | x Pump Air Regulator | = Fluid |

Ratio | Setting | Pressure |

2.Trigger the gun to check the atomization; do not be concerned about the pattern shape yet.

3.Slowly increase the fluid pressure, just to the point where a further increase in fluid pressure does not significantly improve fluid atomization.

Operation

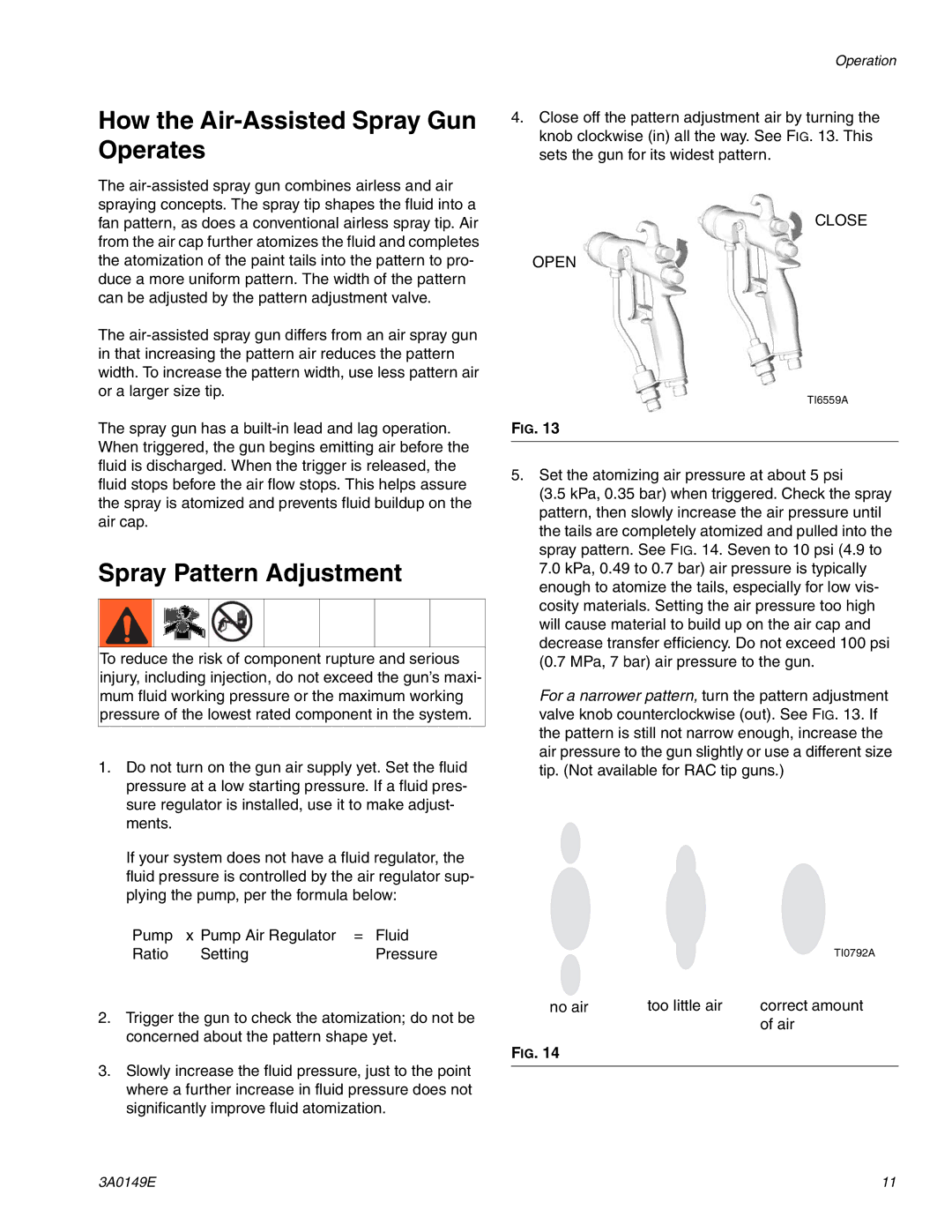

4.Close off the pattern adjustment air by turning the knob clockwise (in) all the way. See FIG. 13. This sets the gun for its widest pattern.

CLOSE

OPEN

TI6559A

FIG. 13

5.Set the atomizing air pressure at about 5 psi

(3.5 kPa, 0.35 bar) when triggered. Check the spray pattern, then slowly increase the air pressure until the tails are completely atomized and pulled into the spray pattern. See FIG. 14. Seven to 10 psi (4.9 to 7.0 kPa, 0.49 to 0.7 bar) air pressure is typically enough to atomize the tails, especially for low vis- cosity materials. Setting the air pressure too high will cause material to build up on the air cap and decrease transfer efficiency. Do not exceed 100 psi (0.7 MPa, 7 bar) air pressure to the gun.

For a narrower pattern, turn the pattern adjustment valve knob counterclockwise (out). See FIG. 13. If the pattern is still not narrow enough, increase the air pressure to the gun slightly or use a different size tip. (Not available for RAC tip guns.)

|

| TI0792A |

no air | too little air | correct amount |

|

| of air |

FIG. 14

3A0149E | 11 |