|

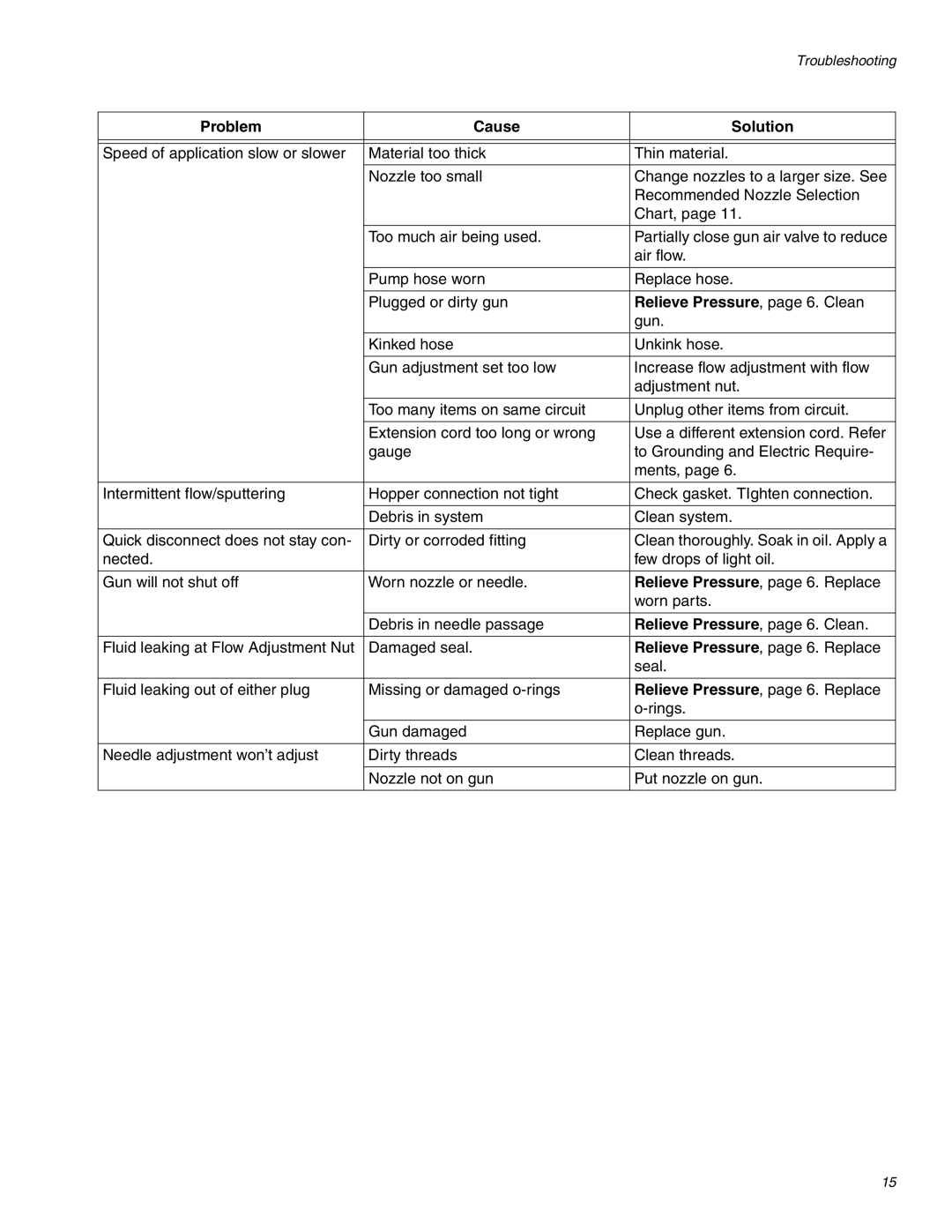

| Troubleshooting |

|

|

|

Problem | Cause | Solution |

|

|

|

|

|

|

Speed of application slow or slower | Material too thick | Thin material. |

|

|

|

| Nozzle too small | Change nozzles to a larger size. See |

|

| Recommended Nozzle Selection |

|

| Chart, page 11. |

|

|

|

| Too much air being used. | Partially close gun air valve to reduce |

|

| air flow. |

|

|

|

| Pump hose worn | Replace hose. |

|

|

|

| Plugged or dirty gun | Relieve Pressure, page 6. Clean |

|

| gun. |

|

|

|

| Kinked hose | Unkink hose. |

|

|

|

| Gun adjustment set too low | Increase flow adjustment with flow |

|

| adjustment nut. |

|

|

|

| Too many items on same circuit | Unplug other items from circuit. |

|

|

|

| Extension cord too long or wrong | Use a different extension cord. Refer |

| gauge | to Grounding and Electric Require- |

|

| ments, page 6. |

|

|

|

Intermittent flow/sputtering | Hopper connection not tight | Check gasket. TIghten connection. |

|

|

|

| Debris in system | Clean system. |

|

|

|

Quick disconnect does not stay con- | Dirty or corroded fitting | Clean thoroughly. Soak in oil. Apply a |

nected. |

| few drops of light oil. |

|

|

|

Gun will not shut off | Worn nozzle or needle. | Relieve Pressure, page 6. Replace |

|

| worn parts. |

|

|

|

| Debris in needle passage | Relieve Pressure, page 6. Clean. |

|

|

|

Fluid leaking at Flow Adjustment Nut | Damaged seal. | Relieve Pressure, page 6. Replace |

|

| seal. |

|

|

|

Fluid leaking out of either plug | Missing or damaged | Relieve Pressure, page 6. Replace |

|

| |

|

|

|

| Gun damaged | Replace gun. |

|

|

|

Needle adjustment won’t adjust | Dirty threads | Clean threads. |

|

|

|

| Nozzle not on gun | Put nozzle on gun. |

|

|

|

15