Troubleshooting

Troubleshooting

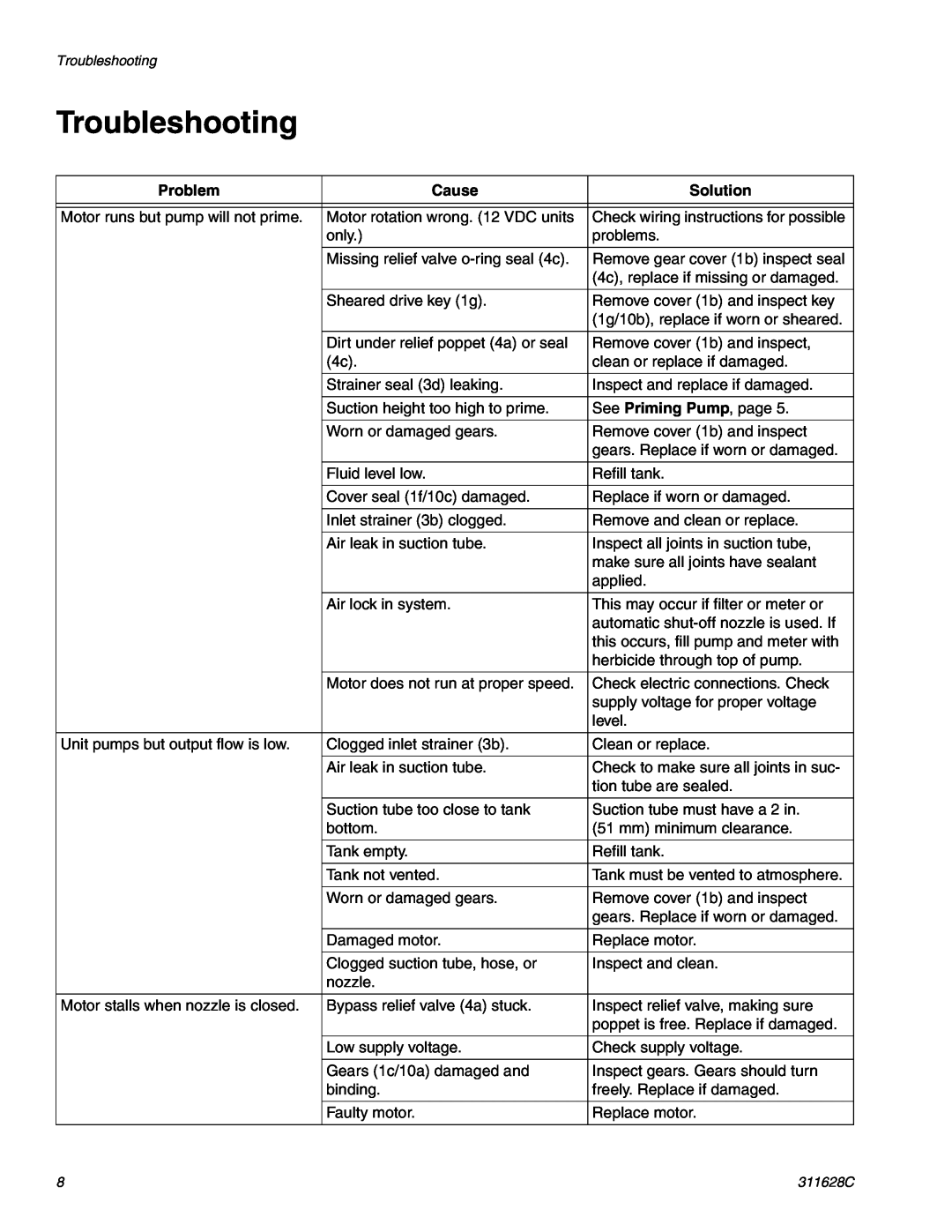

Problem | Cause | Solution |

|

|

|

|

|

|

Motor runs but pump will not prime. | Motor rotation wrong. (12 VDC units | Check wiring instructions for possible |

| only.) | problems. |

|

|

|

| Missing relief valve | Remove gear cover (1b) inspect seal |

|

| (4c), replace if missing or damaged. |

|

|

|

| Sheared drive key (1g). | Remove cover (1b) and inspect key |

|

| (1g/10b), replace if worn or sheared. |

|

|

|

| Dirt under relief poppet (4a) or seal | Remove cover (1b) and inspect, |

| (4c). | clean or replace if damaged. |

|

|

|

| Strainer seal (3d) leaking. | Inspect and replace if damaged. |

|

|

|

| Suction height too high to prime. | See Priming Pump, page 5. |

|

|

|

| Worn or damaged gears. | Remove cover (1b) and inspect |

|

| gears. Replace if worn or damaged. |

|

|

|

| Fluid level low. | Refill tank. |

|

|

|

| Cover seal (1f/10c) damaged. | Replace if worn or damaged. |

|

|

|

| Inlet strainer (3b) clogged. | Remove and clean or replace. |

|

|

|

| Air leak in suction tube. | Inspect all joints in suction tube, |

|

| make sure all joints have sealant |

|

| applied. |

|

|

|

| Air lock in system. | This may occur if filter or meter or |

|

| automatic |

|

| this occurs, fill pump and meter with |

|

| herbicide through top of pump. |

|

|

|

| Motor does not run at proper speed. | Check electric connections. Check |

|

| supply voltage for proper voltage |

|

| level. |

|

|

|

Unit pumps but output flow is low. | Clogged inlet strainer (3b). | Clean or replace. |

|

|

|

| Air leak in suction tube. | Check to make sure all joints in suc- |

|

| tion tube are sealed. |

|

|

|

| Suction tube too close to tank | Suction tube must have a 2 in. |

| bottom. | (51 mm) minimum clearance. |

|

|

|

| Tank empty. | Refill tank. |

|

|

|

| Tank not vented. | Tank must be vented to atmosphere. |

|

|

|

| Worn or damaged gears. | Remove cover (1b) and inspect |

|

| gears. Replace if worn or damaged. |

|

|

|

| Damaged motor. | Replace motor. |

|

|

|

| Clogged suction tube, hose, or | Inspect and clean. |

| nozzle. |

|

|

|

|

Motor stalls when nozzle is closed. | Bypass relief valve (4a) stuck. | Inspect relief valve, making sure |

|

| poppet is free. Replace if damaged. |

|

|

|

| Low supply voltage. | Check supply voltage. |

|

|

|

| Gears (1c/10a) damaged and | Inspect gears. Gears should turn |

| binding. | freely. Replace if damaged. |

|

|

|

| Faulty motor. | Replace motor. |

|

|

|

8 | 311628C |