Installation

Check Fluid Viscosity

To check fluid viscosity you will need:

•a viscosity cup

•a stopwatch.

1. | Completely submerge the viscosity cup in the fluid. |

| Lift the cup out quickly, starting the stopwatch as |

| soon as the cup is completely removed. |

2. | Watch the stream of fluid coming from the bottom of |

| the cup. As soon as there is a break in the stream, |

| shut off the stopwatch. |

4. Fully open atomizing air restrictor valve.

ti1272a

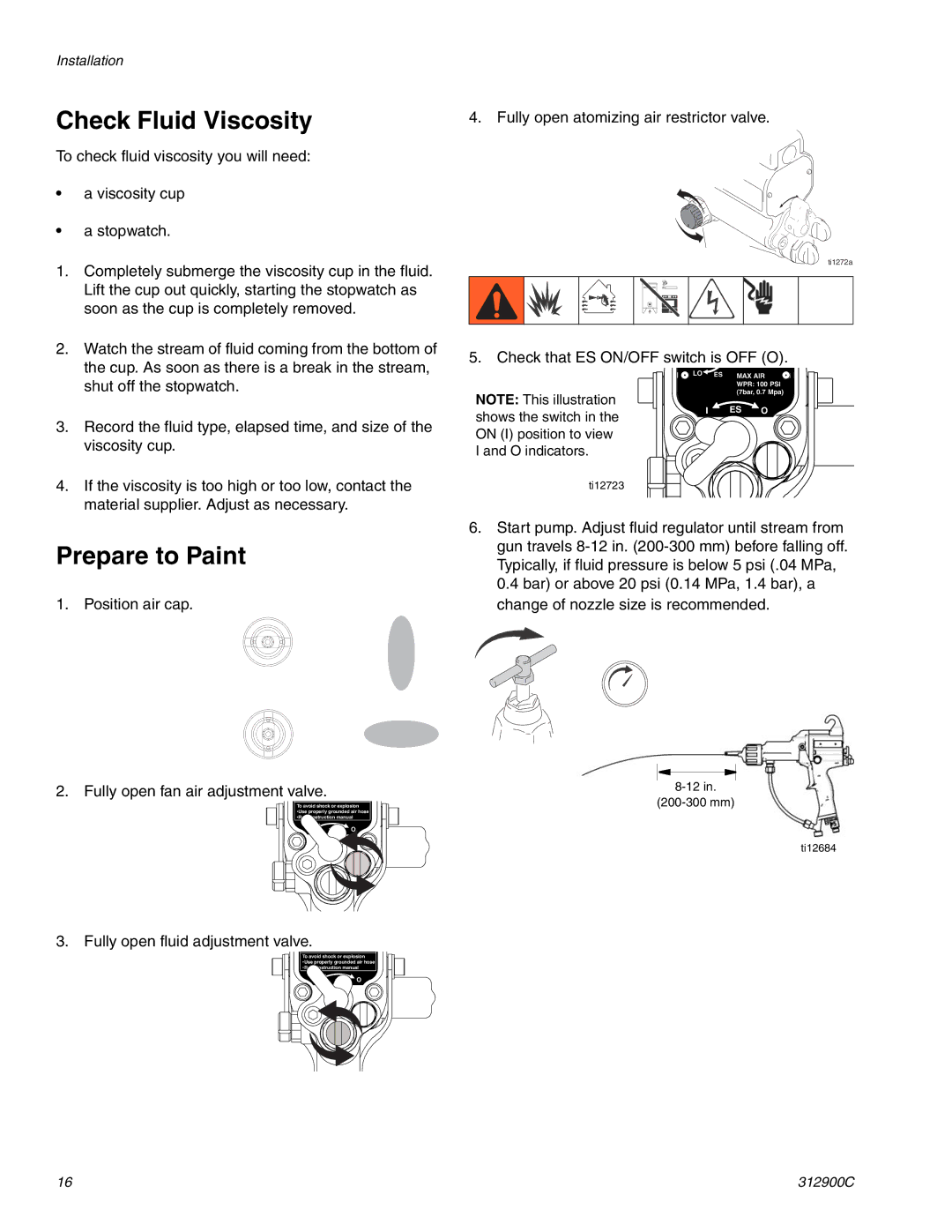

5. Check that ES ON/OFF switch is OFF (O).

![]() LO ES MAX AIR

LO ES MAX AIR

WPR: 100 PSI

NOTE: This illustration

(7bar, 0.7 Mpa)

3. Record the fluid type, elapsed time, and size of the |

viscosity cup. |

shows the switch in the ON (I) position to view I and O indicators.

I ES O

4. If the viscosity is too high or too low, contact the |

material supplier. Adjust as necessary. |

Prepare to Paint

1. Position air cap.

2. Fully open fan air adjustment valve.

To avoid shock or explosion •Use properly grounded air hose •Read instruction manual

I ES O

3. Fully open fluid adjustment valve.

To avoid shock or explosion •Use properly grounded air hose •Read instruction manual

I ES O

ti12723

6.Start pump. Adjust fluid regulator until stream from gun travels

change of nozzle size is recommended.

ti12684

16 | 312900C |