Spray Techniques

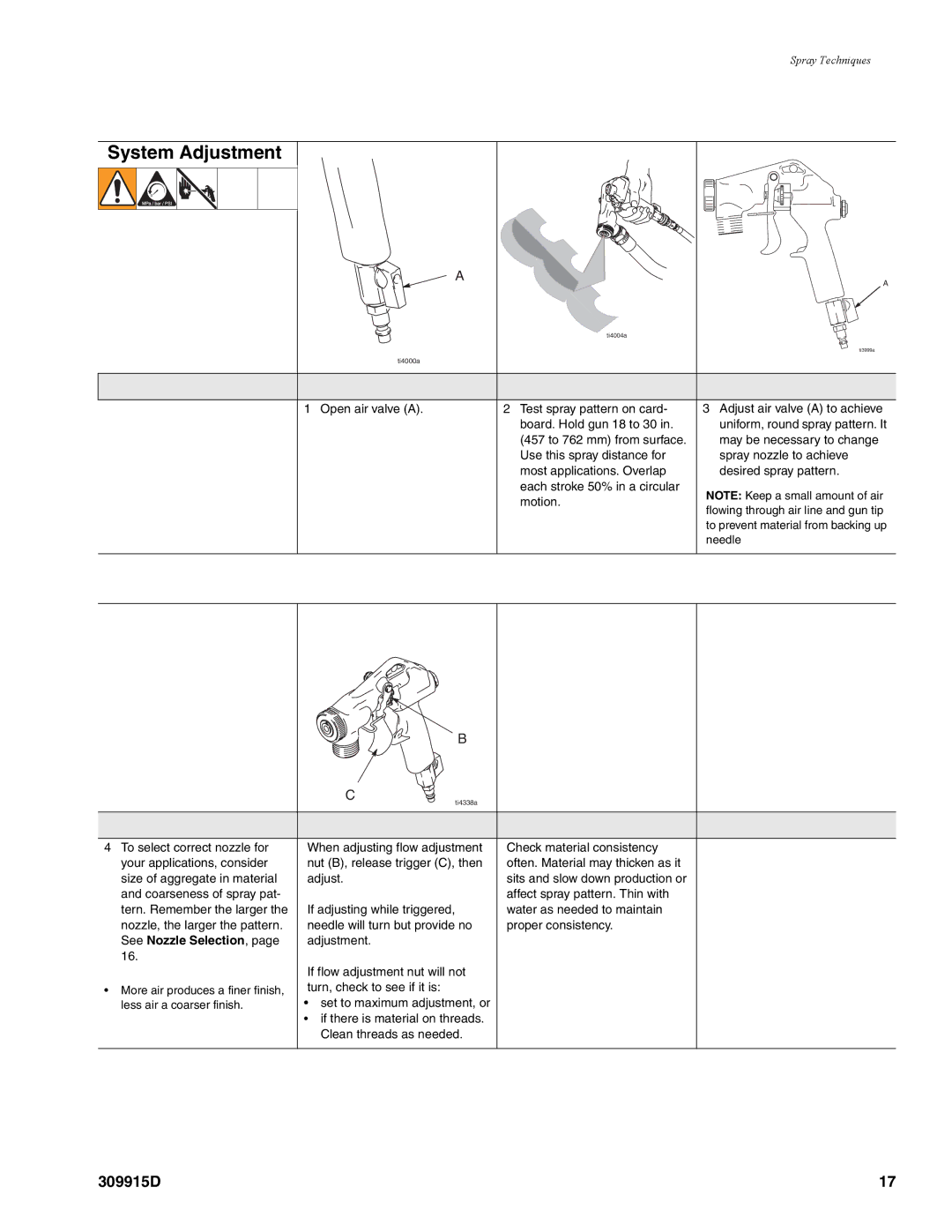

System Adjustment

| A | A |

|

| |

| ti4004a |

|

|

| ti3999a |

ti4000a |

|

|

1 Open air valve (A). | 2 Test spray pattern on card- | 3 Adjust air valve (A) to achieve |

| board. Hold gun 18 to 30 in. | uniform, round spray pattern. It |

| (457 to 762 mm) from surface. | may be necessary to change |

| Use this spray distance for | spray nozzle to achieve |

| most applications. Overlap | desired spray pattern. |

| each stroke 50% in a circular | NOTE: Keep a small amount of air |

| motion. | |

| flowing through air line and gun tip | |

|

| |

|

| to prevent material from backing up |

|

| needle |

|

| B |

|

|

| C |

|

|

| ti4338a |

|

4 | To select correct nozzle for | When adjusting flow adjustment | Check material consistency |

| your applications, consider | nut (B), release trigger (C), then | often. Material may thicken as it |

| size of aggregate in material | adjust. | sits and slow down production or |

| and coarseness of spray pat- |

| affect spray pattern. Thin with |

| tern. Remember the larger the | If adjusting while triggered, | water as needed to maintain |

| nozzle, the larger the pattern. | needle will turn but provide no | proper consistency. |

| See Nozzle Selection, page | adjustment. |

|

| 16. |

|

|

|

| If flow adjustment nut will not |

|

• | More air produces a finer finish, | turn, check to see if it is: |

|

| less air a coarser finish. | • set to maximum adjustment, or |

|

|

| • if there is material on threads. |

|

|

| Clean threads as needed. |

|

309915D | 17 |