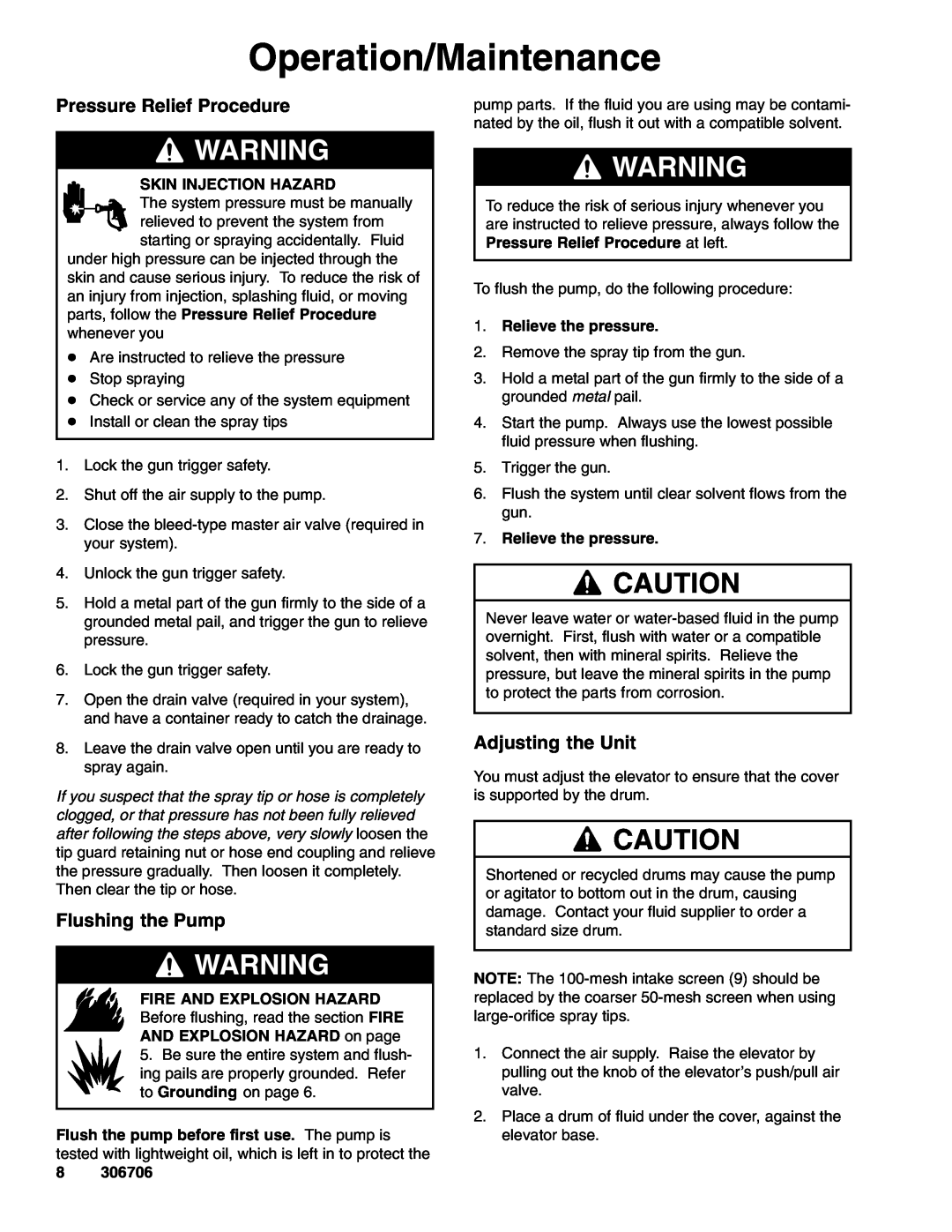

Operation/Maintenance

Pressure Relief Procedure

![]() WARNING

WARNING

SKIN INJECTION HAZARD

The system pressure must be manually relieved to prevent the system from starting or spraying accidentally. Fluid

under high pressure can be injected through the skin and cause serious injury. To reduce the risk of an injury from injection, splashing fluid, or moving parts, follow the Pressure Relief Procedure whenever you

DAre instructed to relieve the pressure

DStop spraying

DCheck or service any of the system equipment

DInstall or clean the spray tips

1.Lock the gun trigger safety.

2.Shut off the air supply to the pump.

3.Close the

4.Unlock the gun trigger safety.

5.Hold a metal part of the gun firmly to the side of a grounded metal pail, and trigger the gun to relieve pressure.

6.Lock the gun trigger safety.

7.Open the drain valve (required in your system), and have a container ready to catch the drainage.

8.Leave the drain valve open until you are ready to spray again.

If you suspect that the spray tip or hose is completely clogged, or that pressure has not been fully relieved after following the steps above, very slowly loosen the tip guard retaining nut or hose end coupling and relieve the pressure gradually. Then loosen it completely. Then clear the tip or hose.

Flushing the Pump

![]() WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Before flushing, read the section FIRE

AND EXPLOSION HAZARD on page

5.Be sure the entire system and flush- ing pails are properly grounded. Refer to Grounding on page 6.

Flush the pump before first use. The pump is tested with lightweight oil, which is left in to protect the

8 306706

pump parts. If the fluid you are using may be contami- nated by the oil, flush it out with a compatible solvent.

![]() WARNING

WARNING

To reduce the risk of serious injury whenever you are instructed to relieve pressure, always follow the Pressure Relief Procedure at left.

To flush the pump, do the following procedure:

1.Relieve the pressure.

2.Remove the spray tip from the gun.

3.Hold a metal part of the gun firmly to the side of a grounded metal pail.

4.Start the pump. Always use the lowest possible fluid pressure when flushing.

5.Trigger the gun.

6.Flush the system until clear solvent flows from the gun.

7.Relieve the pressure.

![]() CAUTION

CAUTION

Never leave water or

Adjusting the Unit

You must adjust the elevator to ensure that the cover is supported by the drum.

![]() CAUTION

CAUTION

Shortened or recycled drums may cause the pump or agitator to bottom out in the drum, causing damage. Contact your fluid supplier to order a standard size drum.

NOTE: The

1.Connect the air supply. Raise the elevator by pulling out the knob of the elevator’s push/pull air valve.

2.Place a drum of fluid under the cover, against the elevator base.