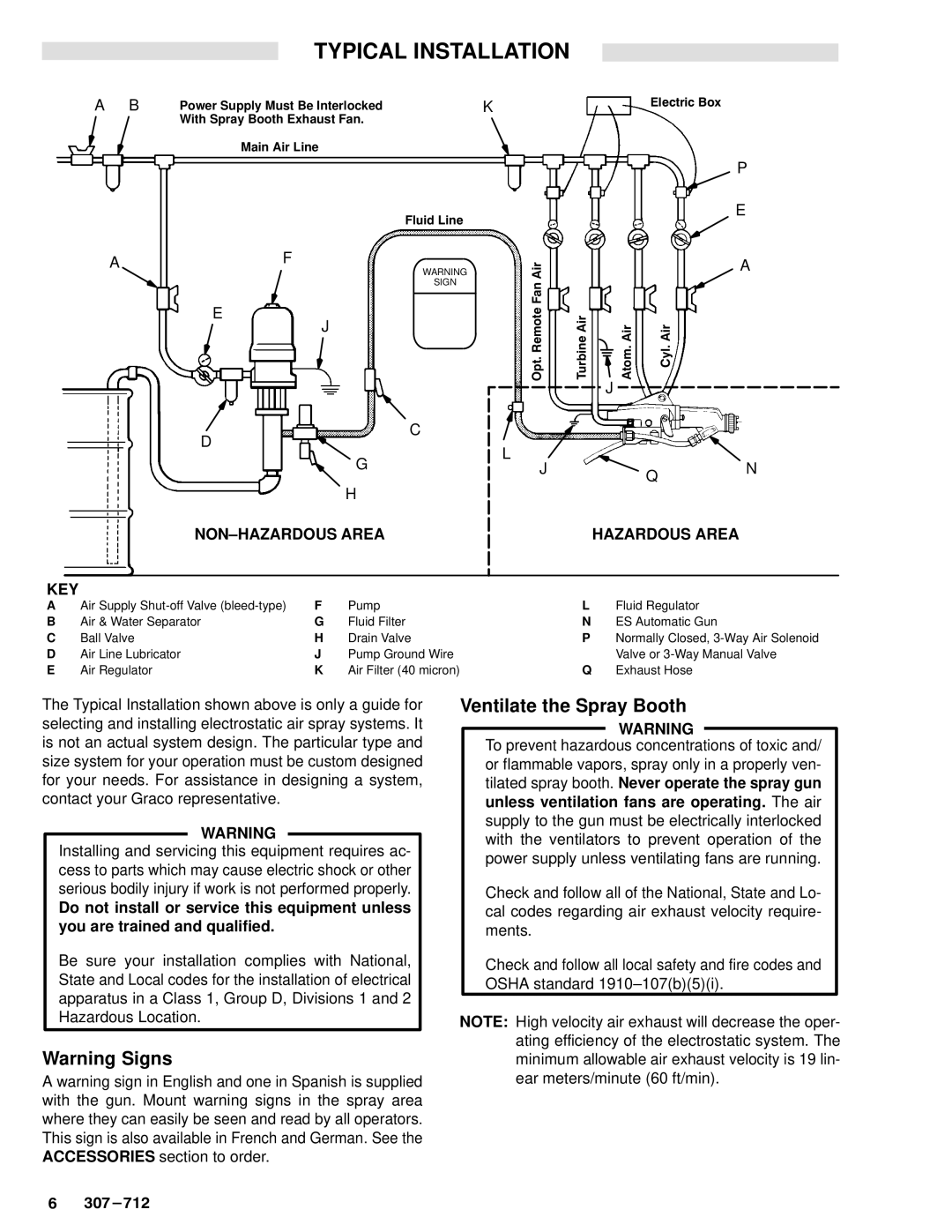

TYPICAL INSTALLATION

A | B | Power Supply Must Be Interlocked | K |

|

| With Spray Booth Exhaust Fan. |

|

|

| Main Air Line |

|

Fluid Line

Electric Box

P

E

AF

E

J

WARNING

SIGN

Opt. Remote Fan Air

A

Turbine Air | Atom. Air | Cyl. Air |

J

| D |

| C |

|

|

|

| L | |

|

|

| G | |

|

|

| J | |

|

|

|

| |

|

|

| H |

|

| NON±HAZARDOUS AREA |

| ||

KEY |

|

|

|

|

A | Air Supply | F | Pump |

|

B | Air & Water Separator | G | Fluid Filter |

|

C | Ball Valve | H | Drain Valve |

|

D | Air Line Lubricator | J | Pump Ground Wire |

|

E | Air Regulator | K | Air Filter (40 micron) |

|

QN

HAZARDOUS AREA

LFluid Regulator

NES Automatic Gun

PNormally Closed,

QExhaust Hose

The Typical Installation shown above is only a guide for selecting and installing electrostatic air spray systems. It is not an actual system design. The particular type and size system for your operation must be custom designed for your needs. For assistance in designing a system, contact your Graco representative.

WARNING

Installing and servicing this equipment requires ac- cess to parts which may cause electric shock or other serious bodily injury if work is not performed properly.

Do not install or service this equipment unless you are trained and qualified.

Be sure your installation complies with National, State and Local codes for the installation of electrical apparatus in a Class 1, Group D, Divisions 1 and 2 Hazardous Location.

Warning Signs

A warning sign in English and one in Spanish is supplied with the gun. Mount warning signs in the spray area where they can easily be seen and read by all operators. This sign is also available in French and German. See the ACCESSORIES section to order.

Ventilate the Spray Booth

WARNING

To prevent hazardous concentrations of toxic and/ or flammable vapors, spray only in a properly ven- tilated spray booth. Never operate the spray gun unless ventilation fans are operating. The air supply to the gun must be electrically interlocked with the ventilators to prevent operation of the power supply unless ventilating fans are running.

Check and follow all of the National, State and Lo- cal codes regarding air exhaust velocity require- ments.

Check and follow all local safety and fire codes and OSHA standard 1910±107(b)(5)(i).

NOTE: High velocity air exhaust will decrease the oper- ating efficiency of the electrostatic system. The minimum allowable air exhaust velocity is 19 lin- ear meters/minute (60 ft/min).

6