Service

Reassembly

1.Clean all parts thoroughly and inspect for wear or damage. Replace parts as necessary.

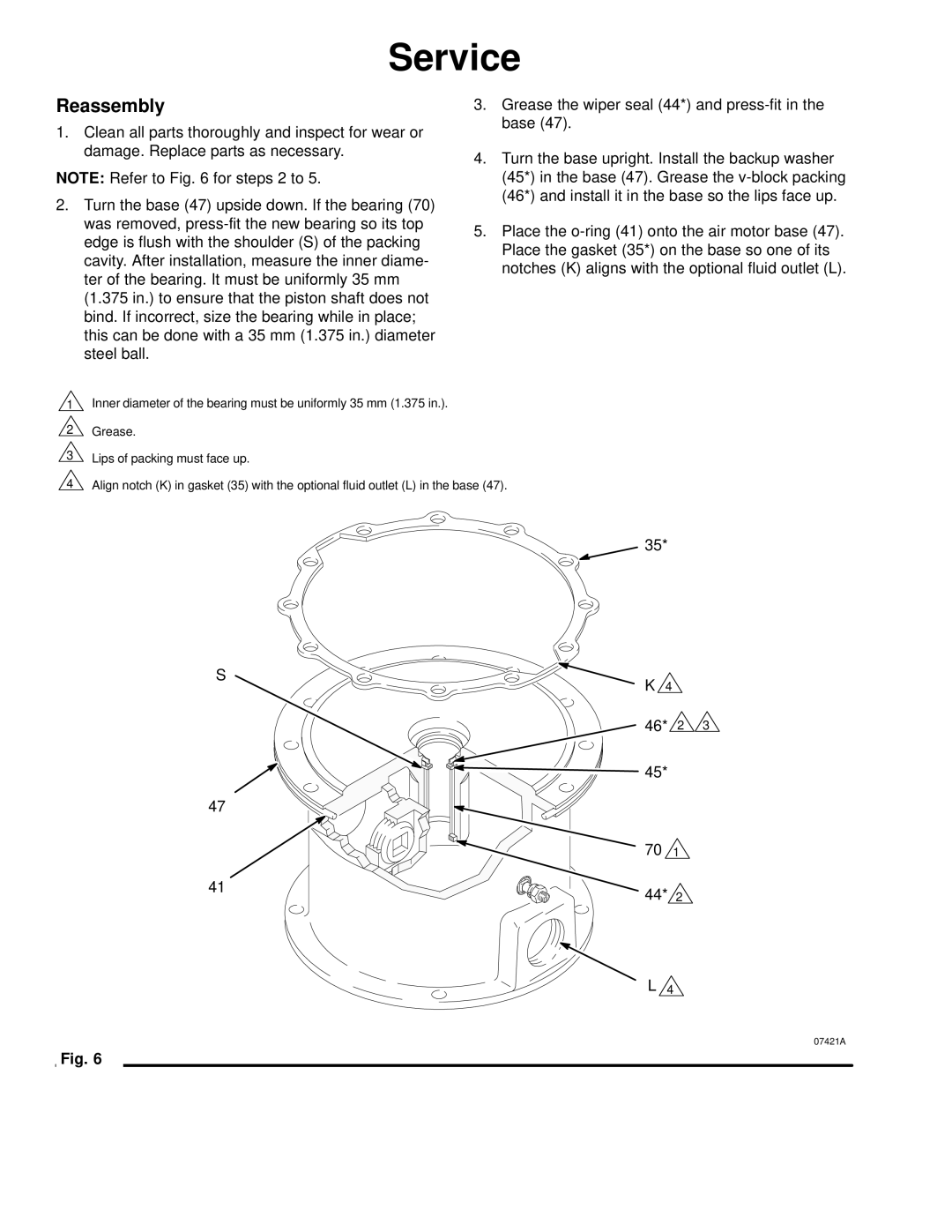

NOTE: Refer to Fig. 6 for steps 2 to 5.

2.Turn the base (47) upside down. If the bearing (70) was removed,

3.Grease the wiper seal (44*) and

4.Turn the base upright. Install the backup washer (45*) in the base (47). Grease the

(46*) and install it in the base so the lips face up.

5.Place the

1Inner diameter of the bearing must be uniformly 35 mm (1.375 in.).

2Grease.

3Lips of packing must face up.

4Align notch (K) in gasket (35) with the optional fluid outlet (L) in the base (47).

S

35*

K 4

| 46* | 2 | 3 |

| 45* |

|

|

47 |

|

|

|

| 70 | 1 |

|

41 | 44* | 2 |

|

|

|

L 4

07421A

Fig. 6

14 307741