Operation

IV. Set the fluid and air pressure.

1.With the system primed and the gun air regulator closed (36), trigger the gun and adjust the pressure pot air regulator (33). Refer to Fig. 5. If available, use the pressure setting provided by your fluid supplier. Otherwise, use the following instructions to deter- mine the fluid pressure.

To determine the fluid pressure setting, hold the gun parallel to the floor. (Be sure to catch the fluid in a container.) With the gun air pressure turned off, trigger the gun. Adjust the pressure pot regula- tor (33) until the straight fluid stream is within the range indicated for the viscosity of your fluid before it drops off. That is your optimal pressure pot air pressure. See Fig. 6 and 7.

NOTE: If you have the HVLP spray gun, do not exceed 15 psi (103 kPa, 1 bar) to maintain HVLP compliance.

Fluid Viscosity | Fluid Droop 1 |

Measured with #2 Zahn cup |

|

Light | |

Medium | |

Heavy |

1Fluid droop: straight stream before fluid

drops off | 1 |

Air Spray Gun

ti12121A

Fig. 6

Fluid Viscosity | Fluid Droop 1 | |

Measured with #2 Zahn cup |

| |

Light | ||

Medium | ||

Heavy | ||

1 | Fluid droop; straight |

|

|

| |

| stream before fluid | 1 |

| drops off | |

|

| |

|

| HVLP Spray Gun |

3.Open the gun air shutoff valve (17a). Partially trigger the gun so only air is emitted. Set the gun air regulator (36) pressure as follows:

HVLP Gun – 60 psi (414 kPa, 4.1 bar)

Air Spray Gun – 65 to 90 psi (448 kPa, 4.5 bar).

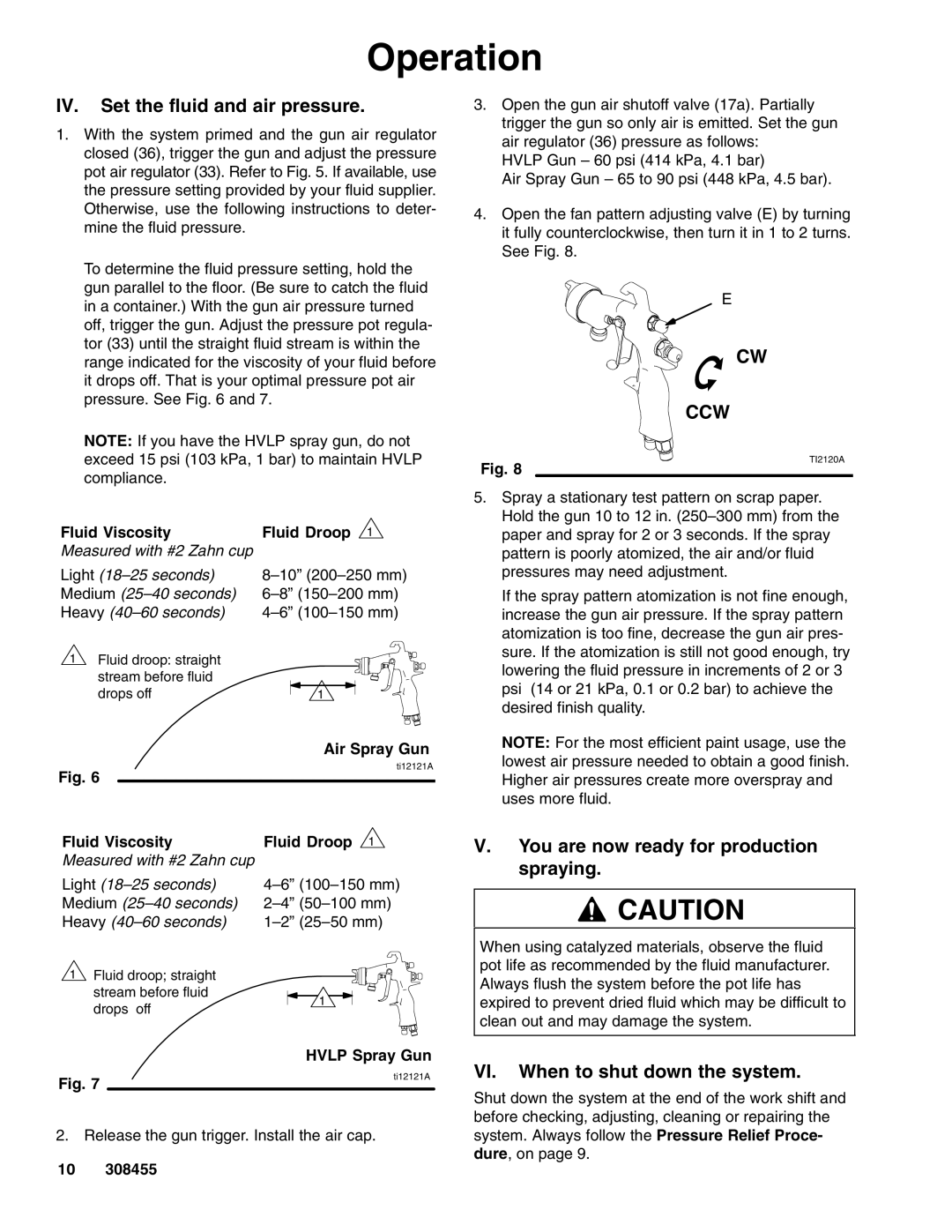

4.Open the fan pattern adjusting valve (E) by turning it fully counterclockwise, then turn it in 1 to 2 turns. See Fig. 8.

E

CW

CCW

TI2120A

Fig. 8

5.Spray a stationary test pattern on scrap paper. Hold the gun 10 to 12 in.

If the spray pattern atomization is not fine enough, increase the gun air pressure. If the spray pattern atomization is too fine, decrease the gun air pres- sure. If the atomization is still not good enough, try lowering the fluid pressure in increments of 2 or 3 psi (14 or 21 kPa, 0.1 or 0.2 bar) to achieve the desired finish quality.

NOTE: For the most efficient paint usage, use the lowest air pressure needed to obtain a good finish. Higher air pressures create more overspray and uses more fluid.

V.You are now ready for production spraying.

![]() CAUTION

CAUTION

When using catalyzed materials, observe the fluid pot life as recommended by the fluid manufacturer. Always flush the system before the pot life has expired to prevent dried fluid which may be difficult to clean out and may damage the system.

Fig. 7

ti12121A

VI. When to shut down the system.

2. Release the gun trigger. Install the air cap.

10308455

Shut down the system at the end of the work shift and before checking, adjusting, cleaning or repairing the system. Always follow the Pressure Relief Proce- dure, on page 9.