Operation

1. Follow pump priming instructions prior to assembling roller.

2. Do not put tip and guard on spray gun.

3. Turn prime/spray valve to SPRAY.

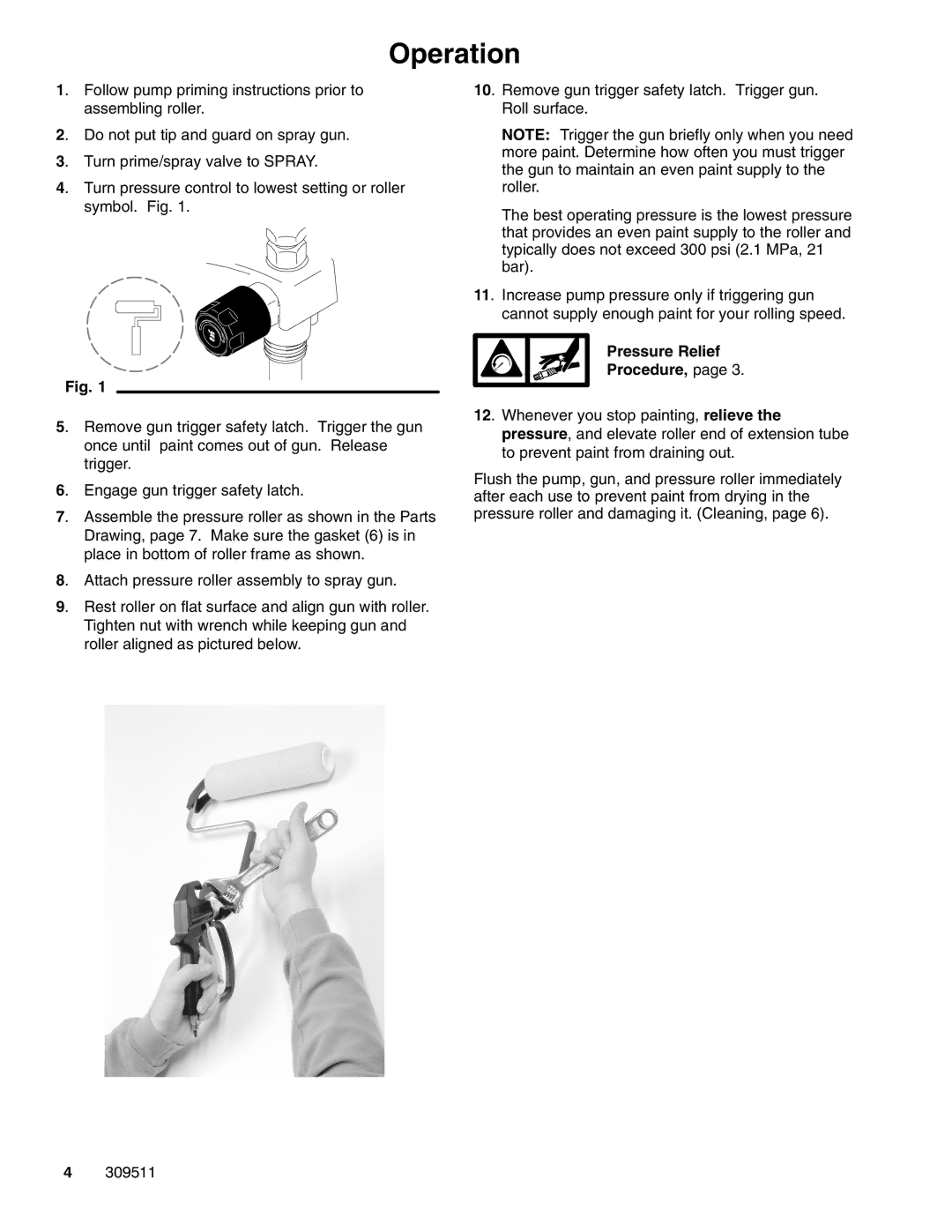

4. Turn pressure control to lowest setting or roller symbol. Fig. 1.

Fig. 1

5. Remove gun trigger safety latch. Trigger the gun once until paint comes out of gun. Release trigger.

6. Engage gun trigger safety latch.

7. Assemble the pressure roller as shown in the Parts Drawing, page 7. Make sure the gasket (6) is in place in bottom of roller frame as shown.

8. Attach pressure roller assembly to spray gun.

9. Rest roller on flat surface and align gun with roller. Tighten nut with wrench while keeping gun and roller aligned as pictured below.

10. Remove gun trigger safety latch. Trigger gun. Roll surface.

NOTE: Trigger the gun briefly only when you need more paint. Determine how often you must trigger the gun to maintain an even paint supply to the roller.

The best operating pressure is the lowest pressure that provides an even paint supply to the roller and typically does not exceed 300 psi (2.1 MPa, 21 bar).

11. Increase pump pressure only if triggering gun cannot supply enough paint for your rolling speed.

Pressure Relief

Procedure, page 3.

12. Whenever you stop painting, relieve the pressure, and elevate roller end of extension tube to prevent paint from draining out.

Flush the pump, gun, and pressure roller immediately after each use to prevent paint from drying in the pressure roller and damaging it. (Cleaning, page 6).

4309511