Pressure Relief Procedure

To relieve fluid and air pressures:

1.Push down Yellow slide valve, P/N

2.Open P/N

3. Open P/N

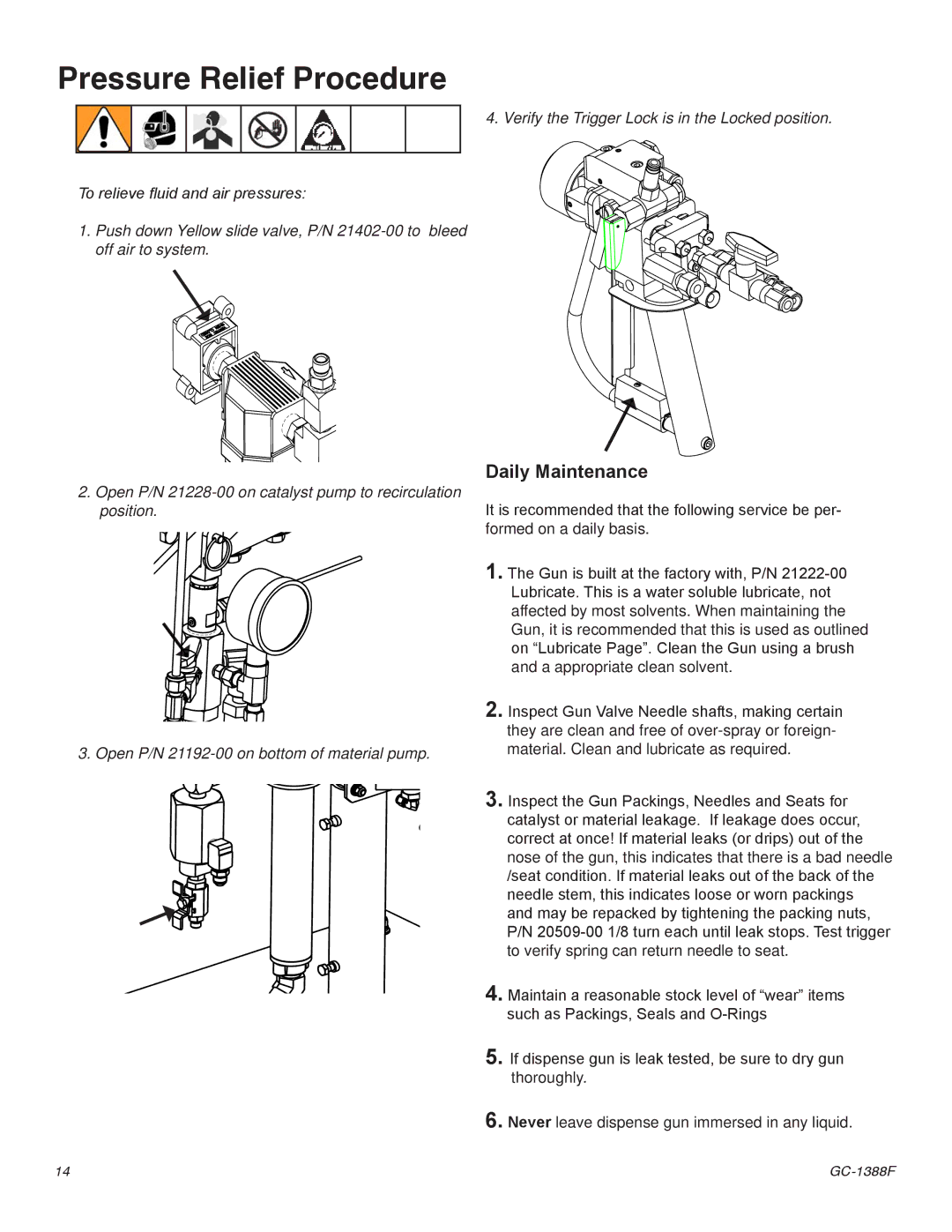

4. Verify the Trigger Lock is in the Locked position.

Daily Maintenance

It is recommended that the following service be per- formed on a daily basis.

1. The Gun is built at the factory with, P/N

2. Inspect Gun Valve Needle shafts, making certain they are clean and free of

3. Inspect the Gun Packings, Needles and Seats for catalyst or material leakage. If leakage does occur, correct at once! If material leaks (or drips) out of the nose of the gun, this indicates that there is a bad needle /seat condition. If material leaks out of the back of the needle stem, this indicates loose or worn packings and may be repacked by tightening the packing nuts, P/N

4. Maintain a reasonable stock level of “wear” items such as Packings, Seals and

5. If dispense gun is leak tested, be sure to dry gun thoroughly.

6. Never leave dispense gun immersed in any liquid.

14 |