REMOVING FROM STORAGE

As fans are removed from storage to be installed in their final location, they should be protected and maintained in a similar fashion, until the fan equipment goes into operation.

Prior to fully assembling and installing the fan and system components, inspect the fan assembly to make sure it is in working order.

1.Check all fasteners, set screws, wheel, bearings, drive, motor base and accessories for tightness.

2.Rotate the fan wheel by hand and assure no parts are rubbing. Access to the wheel is obtained through an access panel located on the side of the fan housing.

3.Ensure proper wheel settings for radial gap and alignment. See below.

Radial Gap, Overlap & Alignment

Efficient fan performance can be maintained by having the correct radial gap, overlap and alignment. These items should be checked before

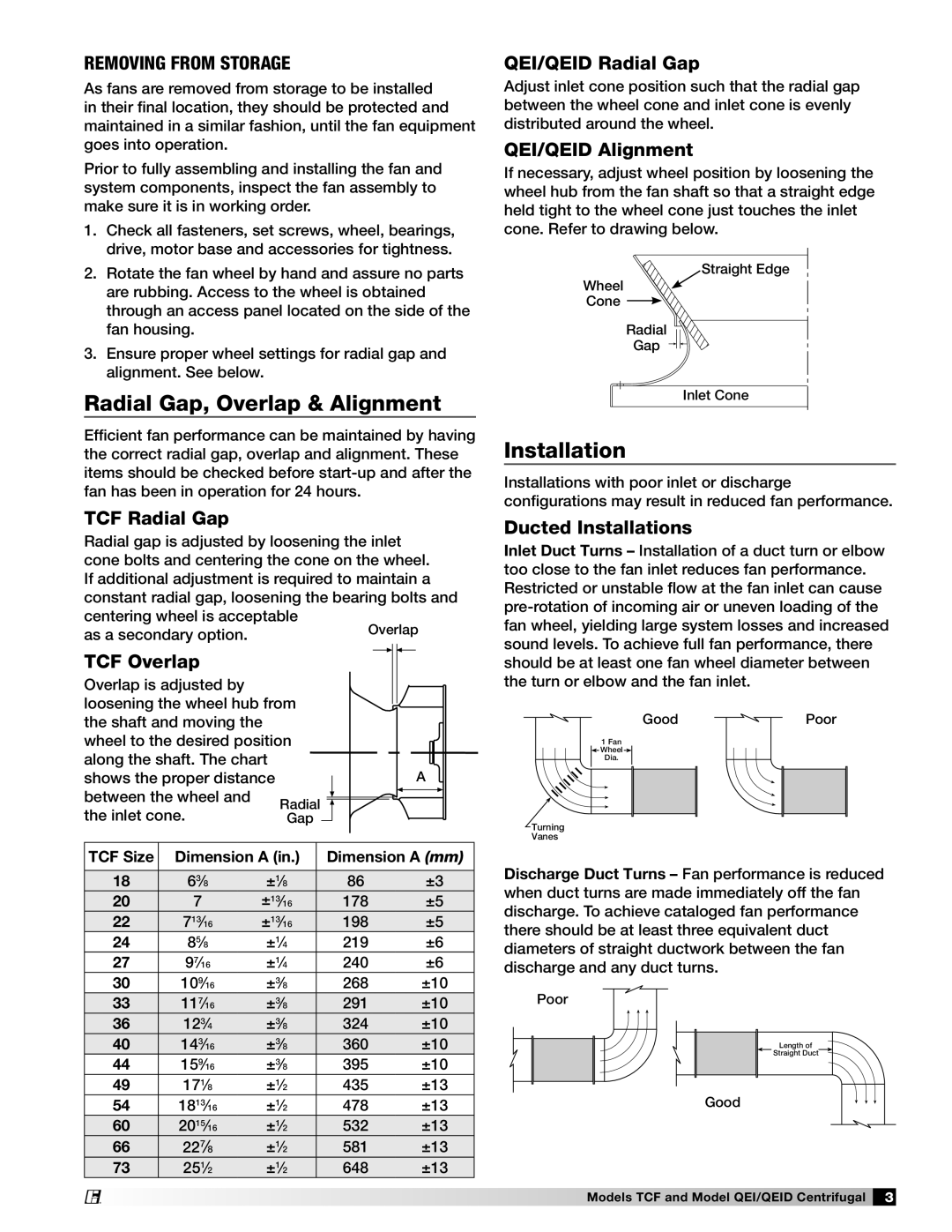

TCF Radial Gap

Radial gap is adjusted by loosening the inlet cone bolts and centering the cone on the wheel. If additional adjustment is required to maintain a constant radial gap, loosening the bearing bolts and

centering wheel is acceptable | Overlap |

as a secondary option. |

TCF Overlap |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| ||

Overlap is adjusted by |

|

|

|

|

|

|

|

|

|

|

| |

loosening the wheel hub from |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| ||||

the shaft and moving the |

|

|

|

|

|

|

|

|

| |||

wheel to the desired position |

|

|

|

|

|

|

|

|

| |||

along the shaft. The chart |

|

|

|

|

|

|

|

|

| |||

shows the proper distance |

|

|

|

|

|

|

| A | ||||

between the wheel and | Radial |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| ||||

the inlet cone. |

|

|

|

|

|

|

|

|

| |||

Gap |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

| |

TCF Size | Dimension A (in.) |

| Dimension A (mm) | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

18 | 63⁄8 | ±1⁄8 |

| 86 |

|

|

|

| ±3 | |||

20 | 7 | ±13⁄16 |

| 178 |

|

|

|

| ±5 | |||

22 | 713⁄16 | ±13⁄16 |

| 198 |

|

|

|

| ±5 | |||

24 | 85⁄8 | ±1⁄4 |

| 219 |

|

|

|

| ±6 | |||

27 | 97⁄16 | ±1⁄4 |

| 240 |

|

|

|

| ±6 | |||

30 | 109⁄16 | ±3⁄8 |

| 268 |

|

|

|

| ±10 | |||

33 | 117⁄16 | ±3⁄8 |

| 291 |

|

|

|

| ±10 | |||

36 | 123⁄4 | ±3⁄8 |

| 324 |

|

|

|

| ±10 | |||

40 | 143⁄16 | ±3⁄8 |

| 360 |

|

|

|

| ±10 | |||

44 | 159⁄16 | ±3⁄8 |

| 395 |

|

|

|

| ±10 | |||

49 | 171⁄8 | ±1⁄2 |

| 435 |

|

|

|

| ±13 | |||

54 | 1813⁄16 | ±1⁄2 |

| 478 |

|

|

|

| ±13 | |||

60 | 2015⁄16 | ±1⁄2 |

| 532 |

|

|

|

| ±13 | |||

66 | 227⁄8 | ±1⁄2 |

| 581 |

|

|

|

| ±13 | |||

73 | 251⁄2 | ±1⁄2 |

| 648 |

|

|

|

| ±13 | |||

QEI/QEID Radial Gap

Adjust inlet cone position such that the radial gap between the wheel cone and inlet cone is evenly distributed around the wheel.

QEI/QEID Alignment

If necessary, adjust wheel position by loosening the wheel hub from the fan shaft so that a straight edge held tight to the wheel cone just touches the inlet cone. Refer to drawing below.

Straight Edge

Wheel

Cone ![]()

Radial

Gap

Inlet Cone

Installation

Installations with poor inlet or discharge configurations may result in reduced fan performance.

Ducted Installations

Inlet Duct Turns – Installation of a duct turn or elbow too close to the fan inlet reduces fan performance. Restricted or unstable flow at the fan inlet can cause

GoodPoor

1 Fan

![]() Wheel

Wheel ![]()

Dia.

Turning

Vanes

Discharge Duct Turns – Fan performance is reduced when duct turns are made immediately off the fan discharge. To achieve cataloged fan performance there should be at least three equivalent duct diameters of straight ductwork between the fan discharge and any duct turns.

Poor

Length of

Straight Duct

Good

®

Models TCF and Model QEI/QEID Centrifugal 3