Non-Ducted Installation

Inlet Clearance – Installation of a fan with an open

inlet too close to a wall or bulkhead will cause |

| |||

reduced fan performance. |

| |||

It is desirable to have a |

|

|

| Wheel |

|

|

| ||

minimum of one fan wheel |

|

|

| |

|

|

|

| 1 Fan |

diameter between the fan |

|

|

| Dia. |

|

|

|

| |

inlet and the wall. |

|

|

|

|

|

|

|

| |

Free Discharge – Free or abrupt discharge into a plenum results in a reduction in fan performance. The effect of discharge static regain is not realized, and performance is reduced.

Duct Connections

It is highly recommended to use a flexible sleeve connection instead of a rigid duct connection. This will reduce vibration transmission through the ductwork.

Slip-Fit End Connection (QEI/QEID)

Directly attach the flexible sleeve to the duct and fan. No additional parts are required.

Flexible Sleeve

Fan | Duct |

|

|

Flanged End Connection (TCF/QEI/QEID) Optional companion flanges are bolted to the fan to provide a

Flexible Sleeve

Fan | Duct |

Companion Flange

Note: Flexible sleeve & attachment hardware not provided.

Unit Start-Up

DANGER

High voltage electrical input is needed for this equipment. This work should be performed by a qualified electrician.

WARNING

Disconnect and secure to the “Off” position all electrical power to the fan prior to inspection or servicing. Failure to comply with this safety precaution could result in serious injury or death.

1.Disconnect and

2.Check all fasteners, set screws and locking collars on the fan, wheel, bearings, drive, motor base and accessories for tightness.

3.Rotate the fan wheel by hand and assure no parts are rubbing.

4.Check for bearing alignment and lubrication.

5.Check the

6.Check all guarding (if supplied) to ensure that it is securely attached and not interfering with rotating parts.

7.Check operation of variable inlet vanes or discharge dampers (if supplied) for freedom of movement.

8.Check all electrical connections for proper attachment.

9.Check housing and ductwork, if accessible, for obstructions and foreign material that may damage the fan wheel.

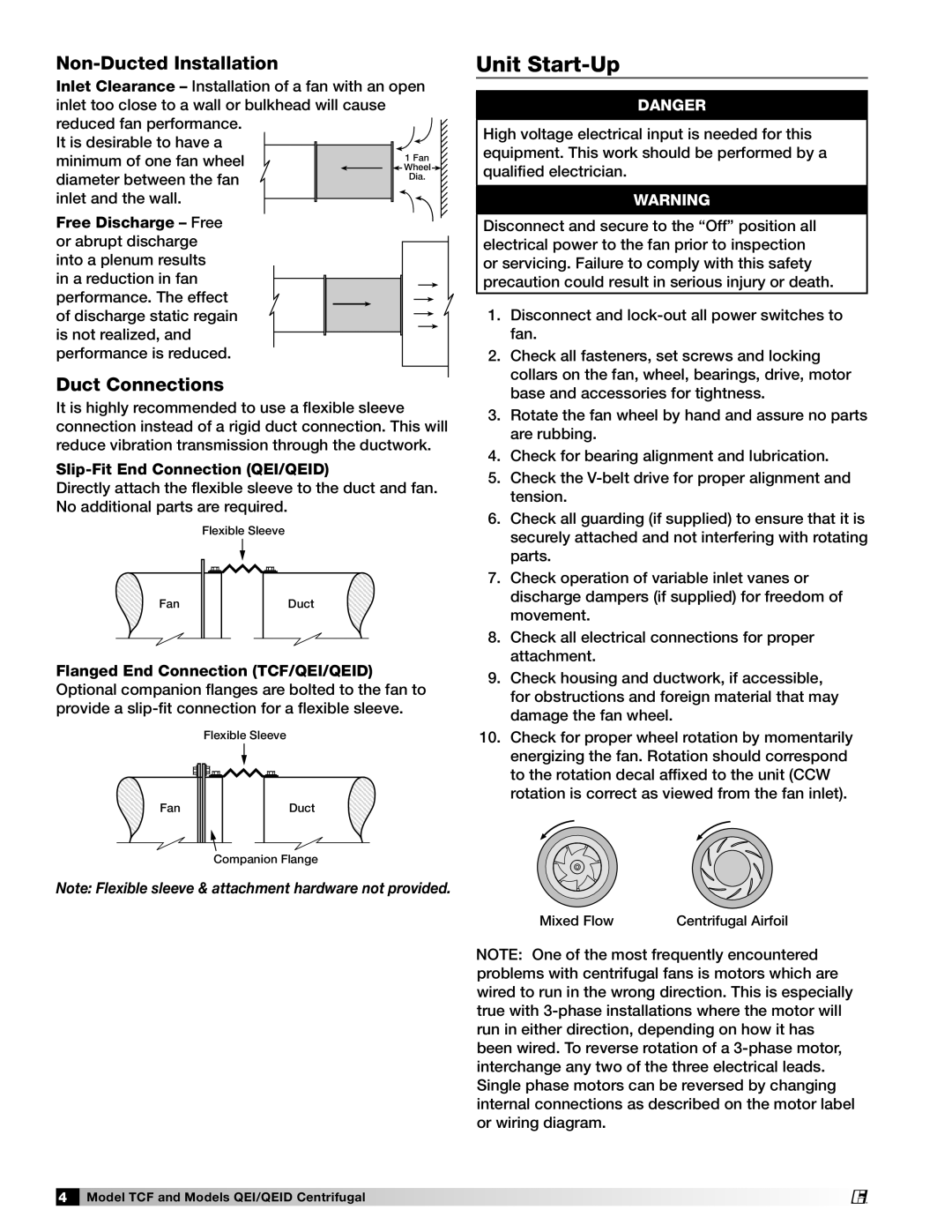

10.Check for proper wheel rotation by momentarily energizing the fan. Rotation should correspond to the rotation decal affixed to the unit (CCW rotation is correct as viewed from the fan inlet).

Mixed Flow | Centrifugal Airfoil |

NOTE: One of the most frequently encountered problems with centrifugal fans is motors which are wired to run in the wrong direction. This is especially true with

4 Model TCF and Models QEI/QEID Centrifugal

®