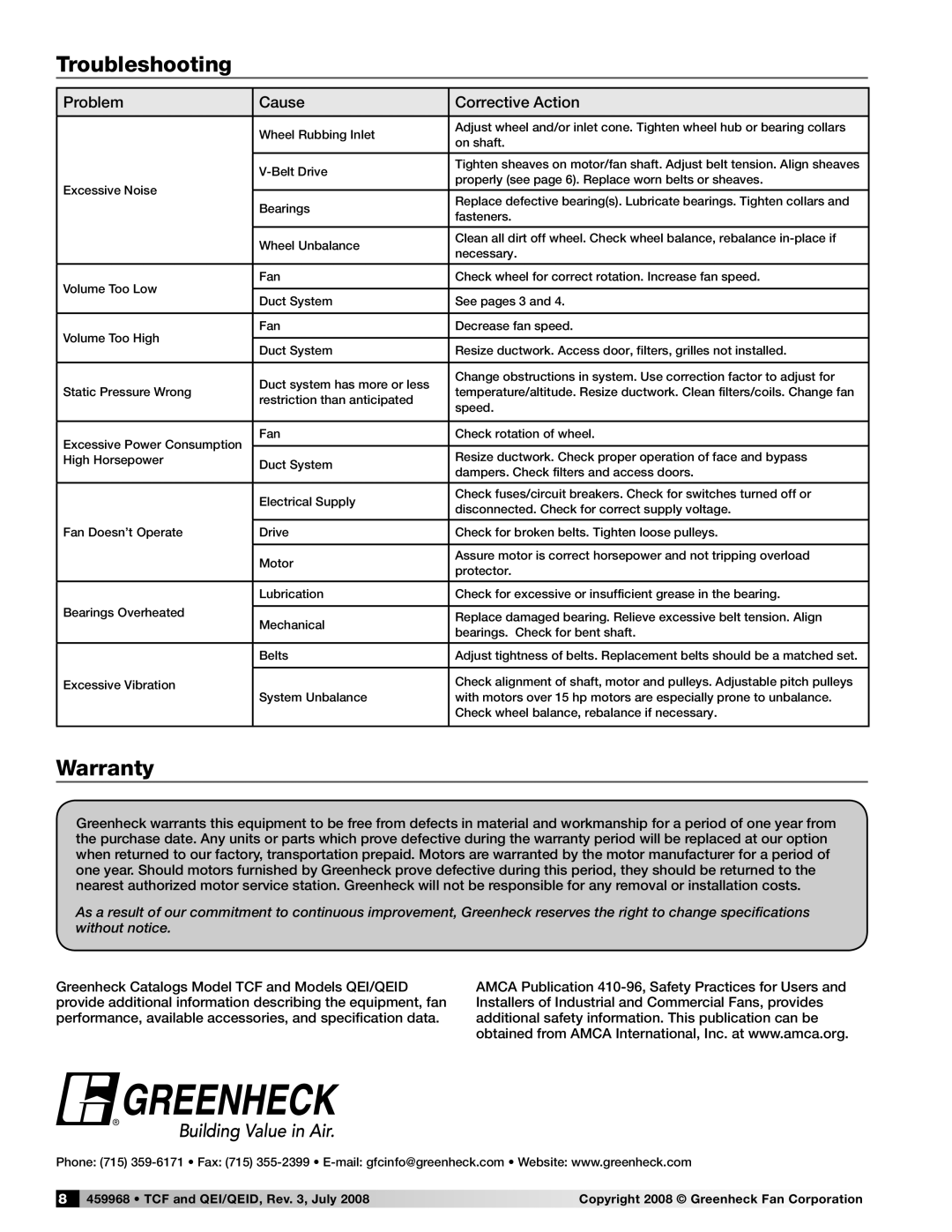

Troubleshooting

Problem | Cause | Corrective Action | |

|

|

| |

| Wheel Rubbing Inlet | Adjust wheel and/or inlet cone. Tighten wheel hub or bearing collars | |

| on shaft. | ||

|

| ||

|

|

| |

| Tighten sheaves on motor/fan shaft. Adjust belt tension. Align sheaves | ||

| properly (see page 6). Replace worn belts or sheaves. | ||

Excessive Noise |

| ||

|

| ||

Bearings | Replace defective bearing(s). Lubricate bearings. Tighten collars and | ||

| |||

| fasteners. | ||

|

| ||

|

|

| |

| Wheel Unbalance | Clean all dirt off wheel. Check wheel balance, rebalance | |

| necessary. | ||

|

| ||

|

|

| |

Volume Too Low | Fan | Check wheel for correct rotation. Increase fan speed. | |

|

| ||

Duct System | See pages 3 and 4. | ||

| |||

|

|

| |

Volume Too High | Fan | Decrease fan speed. | |

|

| ||

Duct System | Resize ductwork. Access door, filters, grilles not installed. | ||

| |||

|

|

| |

| Duct system has more or less | Change obstructions in system. Use correction factor to adjust for | |

Static Pressure Wrong | temperature/altitude. Resize ductwork. Clean filters/coils. Change fan | ||

restriction than anticipated | |||

| speed. | ||

|

| ||

|

|

| |

Excessive Power Consumption | Fan | Check rotation of wheel. | |

|

| ||

| Resize ductwork. Check proper operation of face and bypass | ||

High Horsepower | Duct System | ||

| dampers. Check filters and access doors. | ||

|

| ||

| Electrical Supply | Check fuses/circuit breakers. Check for switches turned off or | |

| disconnected. Check for correct supply voltage. | ||

|

| ||

Fan Doesn’t Operate |

|

| |

Drive | Check for broken belts. Tighten loose pulleys. | ||

|

|

| |

| Motor | Assure motor is correct horsepower and not tripping overload | |

| protector. | ||

|

| ||

|

|

| |

| Lubrication | Check for excessive or insufficient grease in the bearing. | |

Bearings Overheated |

|

| |

Mechanical | Replace damaged bearing. Relieve excessive belt tension. Align | ||

| |||

| bearings. Check for bent shaft. | ||

|

| ||

|

|

| |

| Belts | Adjust tightness of belts. Replacement belts should be a matched set. | |

|

|

| |

Excessive Vibration |

| Check alignment of shaft, motor and pulleys. Adjustable pitch pulleys | |

| System Unbalance | with motors over 15 hp motors are especially prone to unbalance. | |

|

| Check wheel balance, rebalance if necessary. | |

|

|

| |

Warranty |

|

|

Greenheck warrants this equipment to be free from defects in material and workmanship for a period of one year from the purchase date. Any units or parts which prove defective during the warranty period will be replaced at our option when returned to our factory, transportation prepaid. Motors are warranted by the motor manufacturer for a period of one year. Should motors furnished by Greenheck prove defective during this period, they should be returned to the nearest authorized motor service station. Greenheck will not be responsible for any removal or installation costs.

As a result of our commitment to continuous improvement, Greenheck reserves the right to change specifications without notice.

Greenheck Catalogs Model TCF and Models QEI/QEID provide additional information describing the equipment, fan performance, available accessories, and specification data.

AMCA Publication

®

Phone: (715)

8 | 459968 • TCF and QEI/QEID, Rev. 3, July 2008 | Copyright 2008 © Greenheck Fan Corporation |