11.If the fan has inlet vanes, they should be partially closed to reduce power requirements.

12.Fans with

13.Ensure proper wheel location for radial gap, overlap and alignment (see Radial Gap, Overlap & Alignment section on page 3).

14.Grease may be forced out of the bearing seals during initial

15.Check for unusual noise, vibration or overheating of bearings. Refer to the Troubleshooting section of this manual if a problem develops.

Vibration

Excessive vibration is the most frequent problem experienced during initial

The most common sources of vibration are: Wheel unbalance

Drive pulley misalignment Incorrect belt tension Bearing misalignment Mechanical looseness Faulty belts

Drive component unbalance Poor inlet/outlet conditions Foundation stiffness

Many of these conditions can be discovered by careful observation. Refer to the Troubleshooting section

of this manual for corrective actions. If observation cannot locate the source of vibration, a qualified technician using vibration analysis equipment should be consulted. If the problem is wheel unbalance, in‑place balancing can be done providing there is access to the fan wheel. Any correction weights added to the wheel should be welded to either the wheel back

Maintenance

WARNING

Disconnect and secure to the “Off” position all electrical power to the fan prior to inspection or servicing. Failure to comply with this safety precaution could result in serious injury or death.

Once the unit has been put into operation, a routine maintenance schedule should be set up to accomplish the following:

1.Lubrication of bearings and motor.

2.Variable inlet vanes should be checked for freedom of operation and wear.

3.Wheel, housing, bolts and set screws on the entire fan should be checked for tightness.

4.Any dirt accumulation on the wheel or in the housing should be removed to prevent unbalance and possible damage.

5.Isolation bases should be checked for freedom of movement and the bolts for tightness. Springs should be checked for breaks and fatigue. Rubber isolators should be checked for deterioration.

6.Inspect fan impeller and housing looking for fatigue, corrosion or wear.

WARNING

Changing the belts or drives can significantly increase the amp draw of the motor. If changes are made to the drives or belts, the amps must be checked to assure no overamping.

V-Belt Drives

When replacing

Do not install new belts on worn sheaves. If the sheaves have grooves worn in them, they must be replaced before new belts are installed.

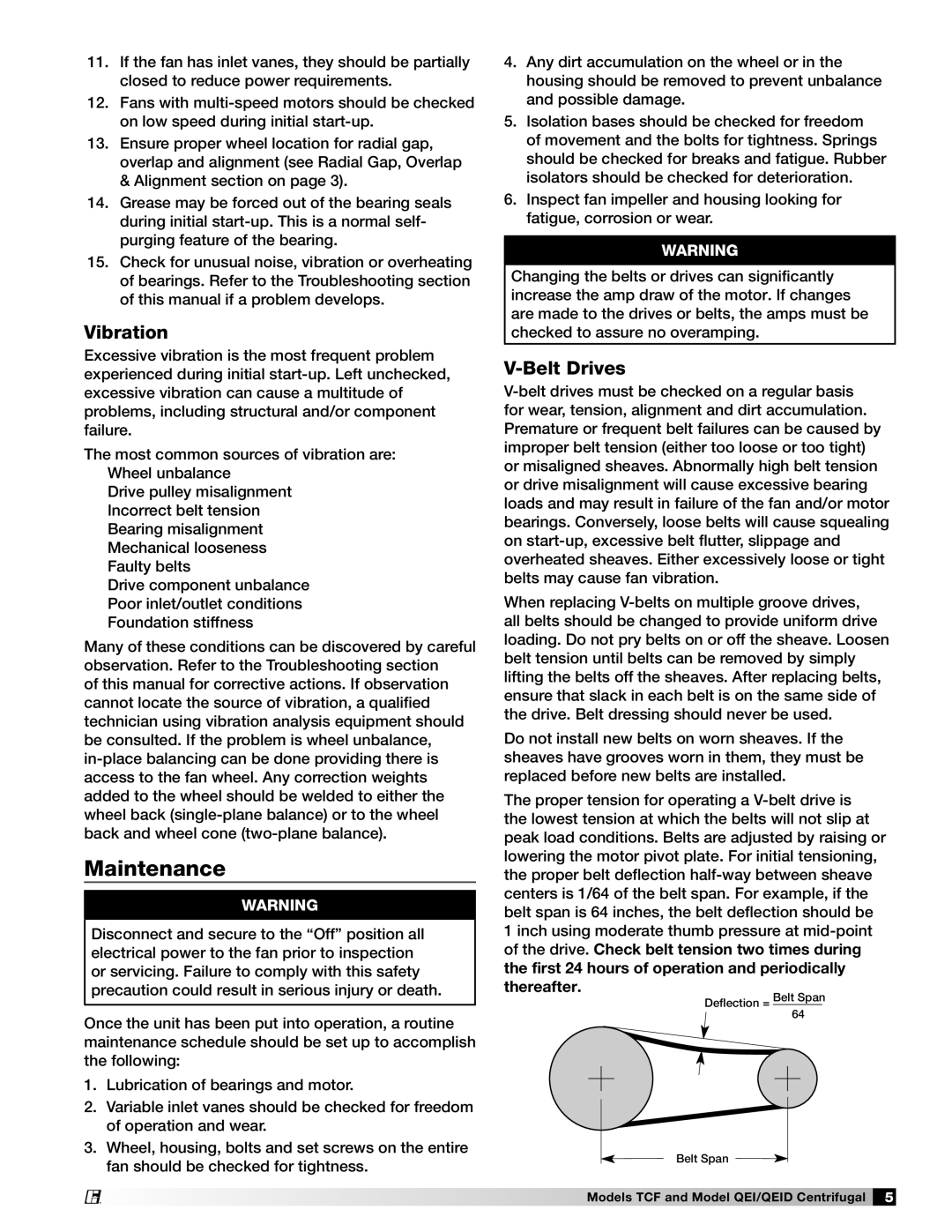

The proper tension for operating a

Belt Span

®

Models TCF and Model QEI/QEID Centrifugal 5