Start-Up of Coil Module

Hot Water and Chilled Water

1. Piping should be in accordance with accepted |

industry standards. Pipework should be supported |

independently of the coils. Water pipes are copper |

with sweat connections. USE WET TOWEL TO |

AVOID BURNING COIL CONNECTION GROMMETS. |

When installing coupling, do not apply undue |

stress to the connection extending through the |

unit. Use a |

the weld between coil connection and header. |

2. Connect the water supply to the bottom |

connection on the |

return to the top connection on the |

side. The extra bottom connection can be used for |

an auxiliary manual drain connection, and the extra |

top connection may be used for an automatic air |

vent, or the extra connections can be capped. To |

3.When connecting suction and liquid connections, make sure the coil is free from all foreign material. Make sure all joints are tight and free of leakage.

4.Greenheck does not supply compressor or condensing units, for further instruction on DX coil installation and operation contact your compressor and/or condenser manufacturer.

DXI coils have dual connections and should be used with two compressors.

WARNING

Standard unit insulation of 1.5 lbs. density has an insulation

For applications where the unit discharge temperatures are below 55°F and the unit is installed in a warm, humid environment, additional insulation may need to be applied to the exterior of the unit to prevent condensation.

ensure proper venting, an external air vent in the |

piping is recommended. Connecting the supply |

and/or return in any other manner will result in very |

poor performance. CAP UNUSED CONNECTIONS. |

3. The air vent at the uppermost point should be |

temporarily opened during system |

release all of the air from the coil. To maintain heat |

transfer capacity, periodically vent any air in coil. |

Vent to be located behind connections side access |

door. |

4. Water coils are not normally recommended for |

use with entering air temperatures below 40°F. |

No control system can be depended on to be |

100% safe against |

Glycol solutions or brines are the only safe media |

for operation of water coils with low entering air |

conditions. |

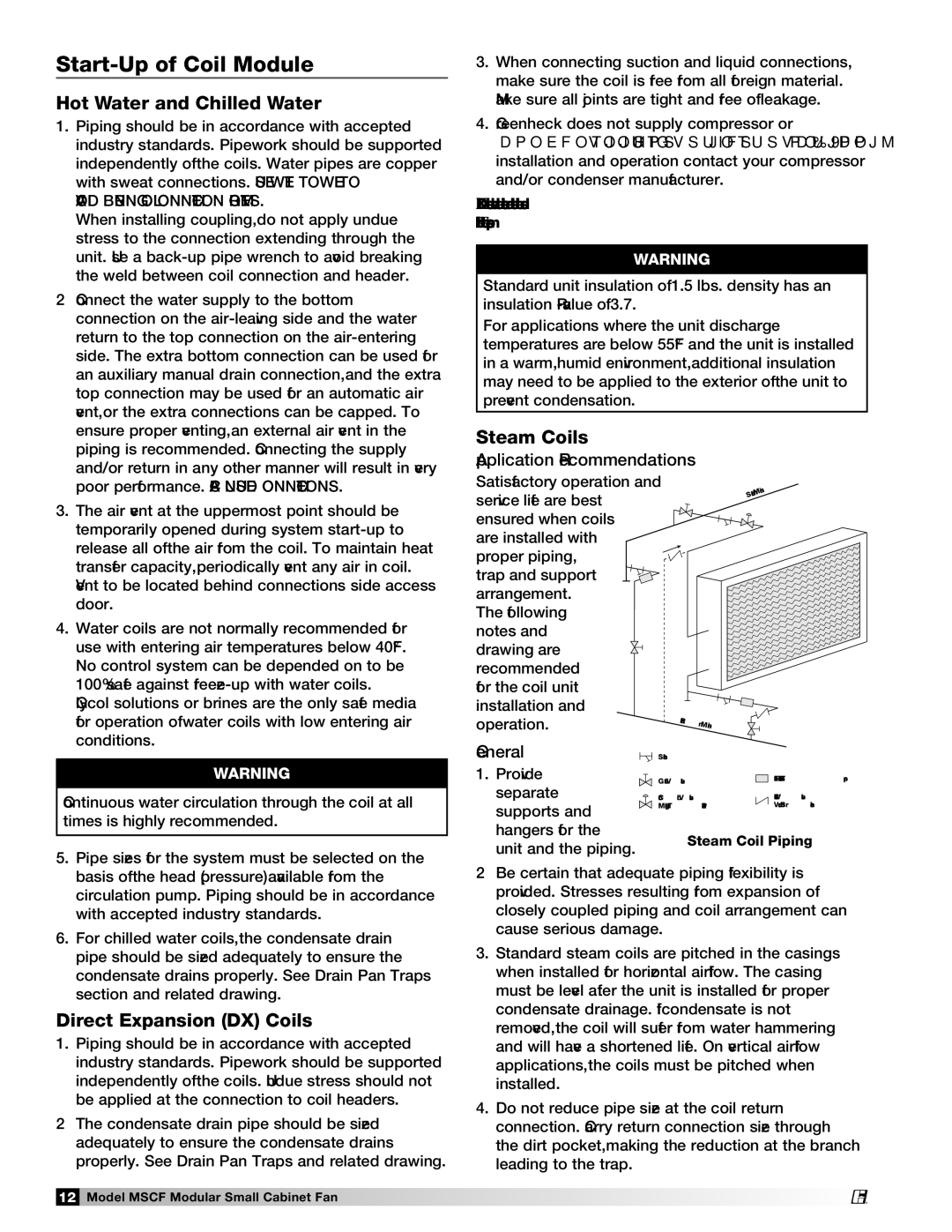

Steam Coils

Application Recommendations

Satisfactory operation and |

|

|

service life are best |

|

|

ensured when coils |

|

|

are installed with |

|

|

proper piping, |

|

|

trap and support |

|

|

arrangement. |

|

|

The following |

|

|

notes and |

|

|

drawing are |

|

|

recommended |

|

|

for the coil unit |

|

|

installation and |

| Main |

operation. | Return |

Main

Steam

WARNING

Continuous water circulation through the coil at all times is highly recommended.

5.Pipe sizes for the system must be selected on the basis of the head (pressure) available from the circulation pump. Piping should be in accordance with accepted industry standards.

6.For chilled water coils, the condensate drain pipe should be sized adequately to ensure the condensate drains properly. See Drain Pan Traps section and related drawing.

Direct Expansion (DX) Coils

1.Piping should be in accordance with accepted industry standards. Pipework should be supported independently of the coils. Undue stress should not be applied at the connection to coil headers.

2.The condensate drain pipe should be sized adequately to ensure the condensate drains properly. See Drain Pan Traps and related drawing.

General | Strainer |

|

|

1. Provide | Gate Valve |

| Float & Thermostat Trap |

| |||

separate |

| Check Valve | |

Control Valve |

| ||

supports and | Modulating |

| Vacuum Breaker |

|

|

|

hangers for the | Steam Coil Piping | |

unit and the piping. | ||

|

2.Be certain that adequate piping flexibility is provided. Stresses resulting from expansion of closely coupled piping and coil arrangement can cause serious damage.

3.Standard steam coils are pitched in the casings when installed for horizontal airflow. The casing must be level after the unit is installed for proper condensate drainage. If condensate is not removed, the coil will suffer from water hammering and will have a shortened life. On vertical airflow applications, the coils must be pitched when installed.

4.Do not reduce pipe size at the coil return connection. Carry return connection size through the dirt pocket, making the reduction at the branch leading to the trap.

12 Model MSCF Modular Small Cabinet Fan

®