General - continued

5.It is recommended that vacuum breakers be installed on all applications to prevent retaining condensate in the coil. Generally, the vacuum breaker is to be connected between the coil inlet and the return main. The vacuum breaker should be open to the atmosphere and the trap design should allow venting of large quantities of air.

6.Do not attempt to lift condensate when using modulating or

7.Do not reduce the pipe size leaving the coil.

Traps

1.Size traps in accordance with the manufacturer’s recommendations. Be certain that the required pressure differential will always be available. DO NOT UNDERSIZE.

2.Float and thermostatic or bucket traps are recommended for low pressure steam. On high pressure systems, bucket traps are normally recommended. The thermostatic traps should be used only for air venting.

3.Bucket traps are recommended for use with

4.Locate traps at least 12 inches below the coil return connection.

Controls

1.On high pressure installations, a

2.Modulating valves must be sized properly. DO NOT UNDERSIZE.

Freezing Conditions (entering air below 35°F)

1.5 PSI steam must be supplied to the coil at all times.

2.Modulating valves are not recommended. Control should be by means of face and bypass dampers.

3.Provision should always be made to thoroughly mix fresh air and return air before it enters the coil on return air units. Also, temperature control elements must be properly located to obtain true air mixture temperatures.

4.As additional protection against

5.On

6.Provision must be made to close fresh air dampers if steam supply pressure falls below minimum specified.

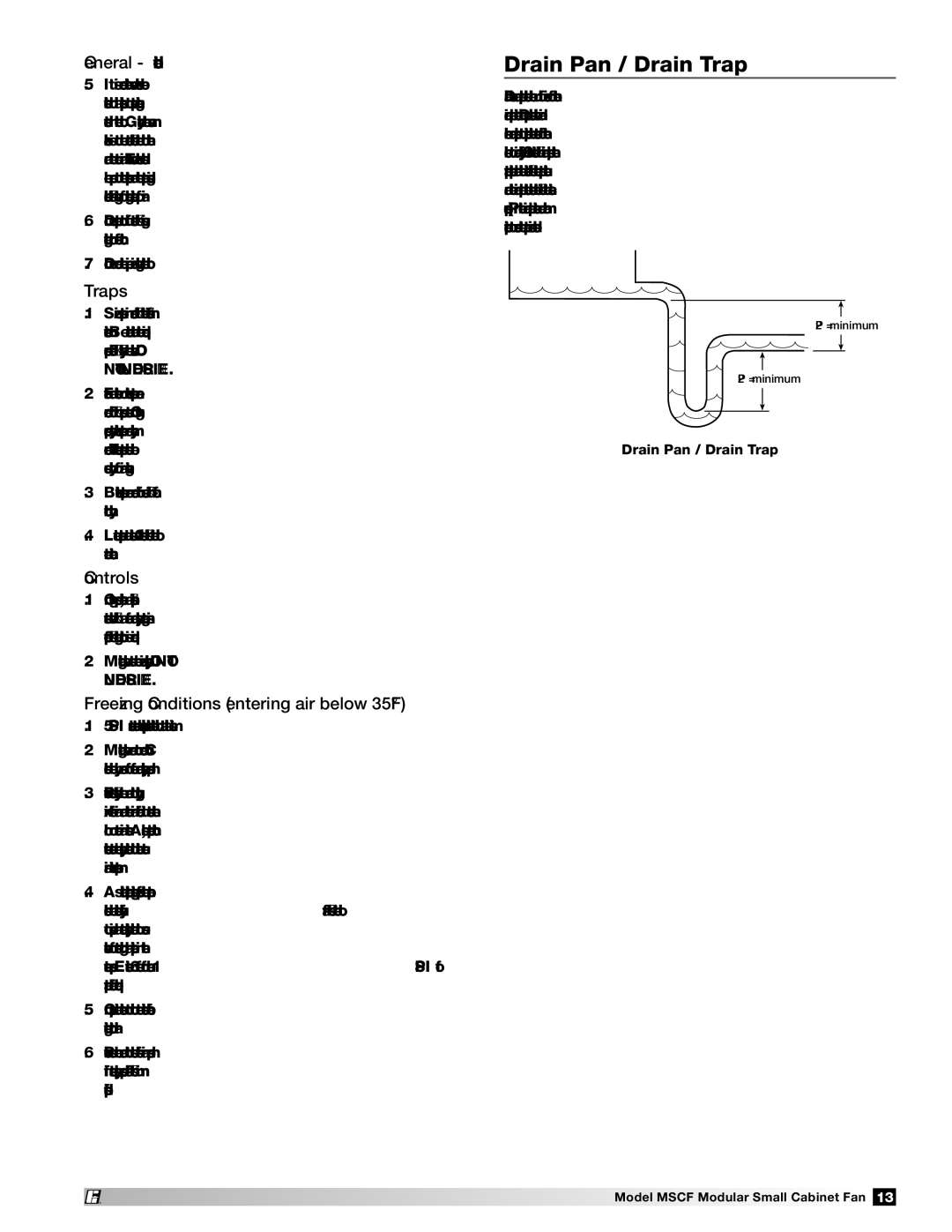

Drain Pan / Drain Trap

Drain lines and traps should be run full size from the drain pan connection. Drain pans should have drain lines and traps to permit the condensate from the coils to drain freely. On all units with drain pans, the trap depth and the distance between the trap outlet and the drain pan outlet should be twice the static pressure (P) in the drain pan section under normal operation to assure the trap remains sealed.

2P = minimum

2P = minimum

Drain Pan / Drain Trap

®

Model MSCF Modular Small Cabinet Fan 13