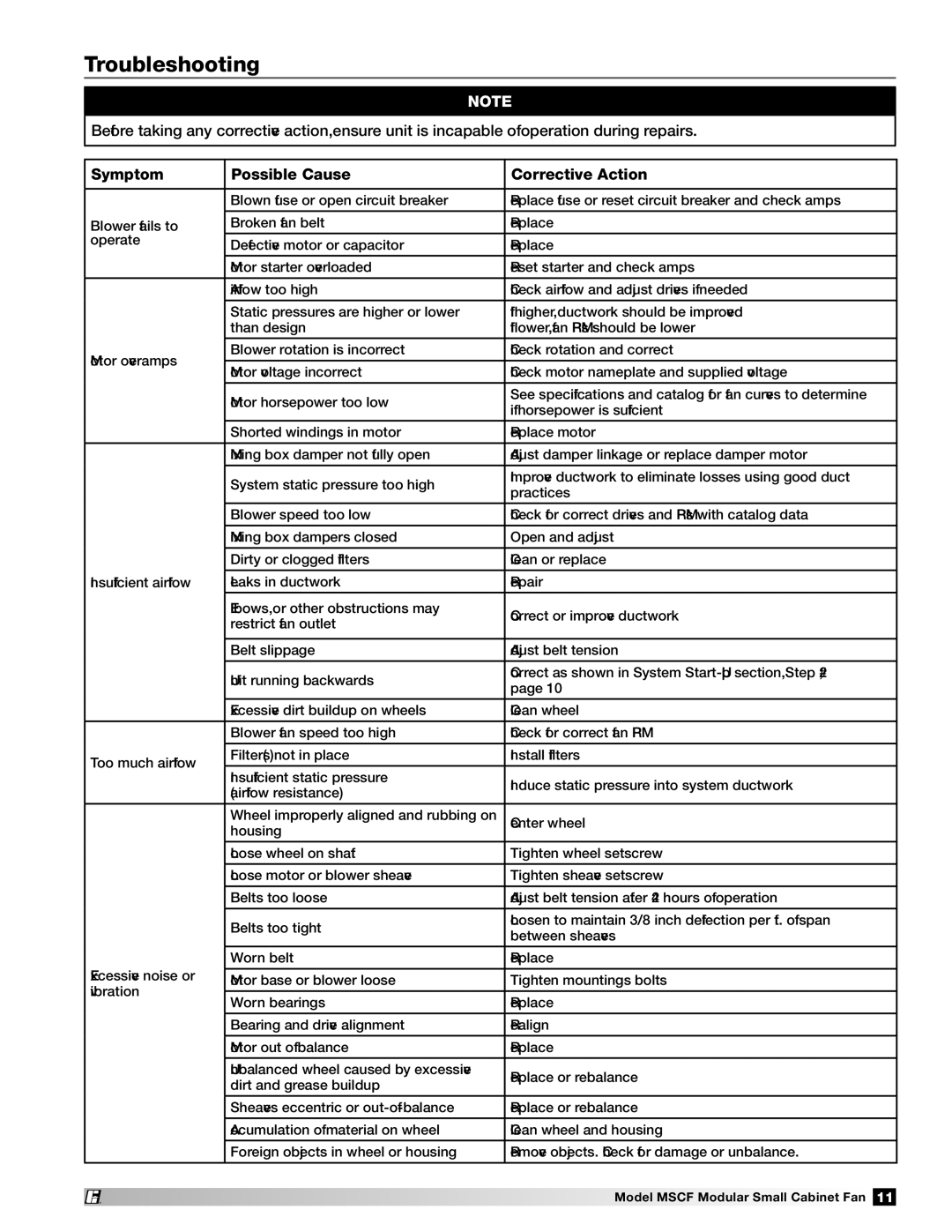

Troubleshooting

| NOTE |

| |

|

| ||

Before taking any corrective action, ensure unit is incapable of operation during repairs. |

| ||

|

|

|

|

|

|

|

|

Symptom | Possible Cause | Corrective Action |

|

|

|

|

|

| Blown fuse or open circuit breaker | Replace fuse or reset circuit breaker and check amps |

|

|

|

|

|

Blower fails to | Broken fan belt | Replace |

|

operate | Defective motor or capacitor | Replace |

|

|

| ||

|

|

|

|

| Motor starter overloaded | Reset starter and check amps |

|

|

|

|

|

| Airflow too high | Check airflow and adjust drives if needed |

|

|

|

|

|

| Static pressures are higher or lower | If higher, ductwork should be improved |

|

| than design | If lower, fan RPMs should be lower |

|

Motor overamps | Blower rotation is incorrect | Check rotation and correct |

|

|

|

| |

Motor voltage incorrect | Check motor nameplate and supplied voltage |

| |

|

| ||

|

|

|

|

| Motor horsepower too low | See specifications and catalog for fan curves to determine |

|

| if horsepower is sufficient |

| |

|

|

| |

|

|

|

|

| Shorted windings in motor | Replace motor |

|

|

|

|

|

| Mixing box damper not fully open | Adjust damper linkage or replace damper motor |

|

|

|

|

|

| System static pressure too high | Improve ductwork to eliminate losses using good duct |

|

| practices |

| |

|

|

| |

|

|

|

|

| Blower speed too low | Check for correct drives and RPMs with catalog data |

|

|

|

|

|

| Mixing box dampers closed | Open and adjust |

|

|

|

|

|

| Dirty or clogged filters | Clean or replace |

|

|

|

|

|

Insufficient airflow | Leaks in ductwork | Repair |

|

| Elbows, or other obstructions may | Correct or improve ductwork |

|

| restrict fan outlet |

| |

|

|

| |

|

|

|

|

| Belt slippage | Adjust belt tension |

|

|

|

|

|

| Unit running backwards | Correct as shown in System |

|

| page 10 |

| |

|

|

| |

| Excessive dirt buildup on wheels | Clean wheel |

|

|

|

|

|

| Blower fan speed too high | Check for correct fan RPM |

|

|

|

|

|

Too much airflow | Filter(s) not in place | Install filters |

|

|

|

| |

Insufficient static pressure | Induce static pressure into system ductwork |

| |

|

| ||

| (airflow resistance) |

| |

|

|

| |

|

|

|

|

| Wheel improperly aligned and rubbing on | Center wheel |

|

| housing |

|

|

| Loose wheel on shaft | Tighten wheel setscrew |

|

|

|

|

|

| Loose motor or blower sheave | Tighten sheave setscrew |

|

|

|

|

|

| Belts too loose | Adjust belt tension after 24 hours of operation |

|

|

|

|

|

| Belts too tight | Loosen to maintain 3/8 inch deflection per ft. of span |

|

| between sheaves |

| |

|

|

| |

|

|

|

|

| Worn belt | Replace |

|

Excessive noise or |

|

|

|

Motor base or blower loose | Tighten mountings bolts |

| |

vibration |

| ||

|

|

| |

Worn bearings | Replace |

| |

|

| ||

|

|

|

|

| Bearing and drive alignment | Realign |

|

|

|

|

|

| Motor out of balance | Replace |

|

|

|

|

|

| Unbalanced wheel caused by excessive | Replace or rebalance |

|

| dirt and grease buildup |

| |

|

|

| |

|

|

|

|

| Sheaves eccentric or | Replace or rebalance |

|

|

|

|

|

| Accumulation of material on wheel | Clean wheel and housing |

|

|

|

|

|

| Foreign objects in wheel or housing | Remove objects. Check for damage or unbalance. |

|

|

|

|

|

®

Model MSCF Modular Small Cabinet Fan 11