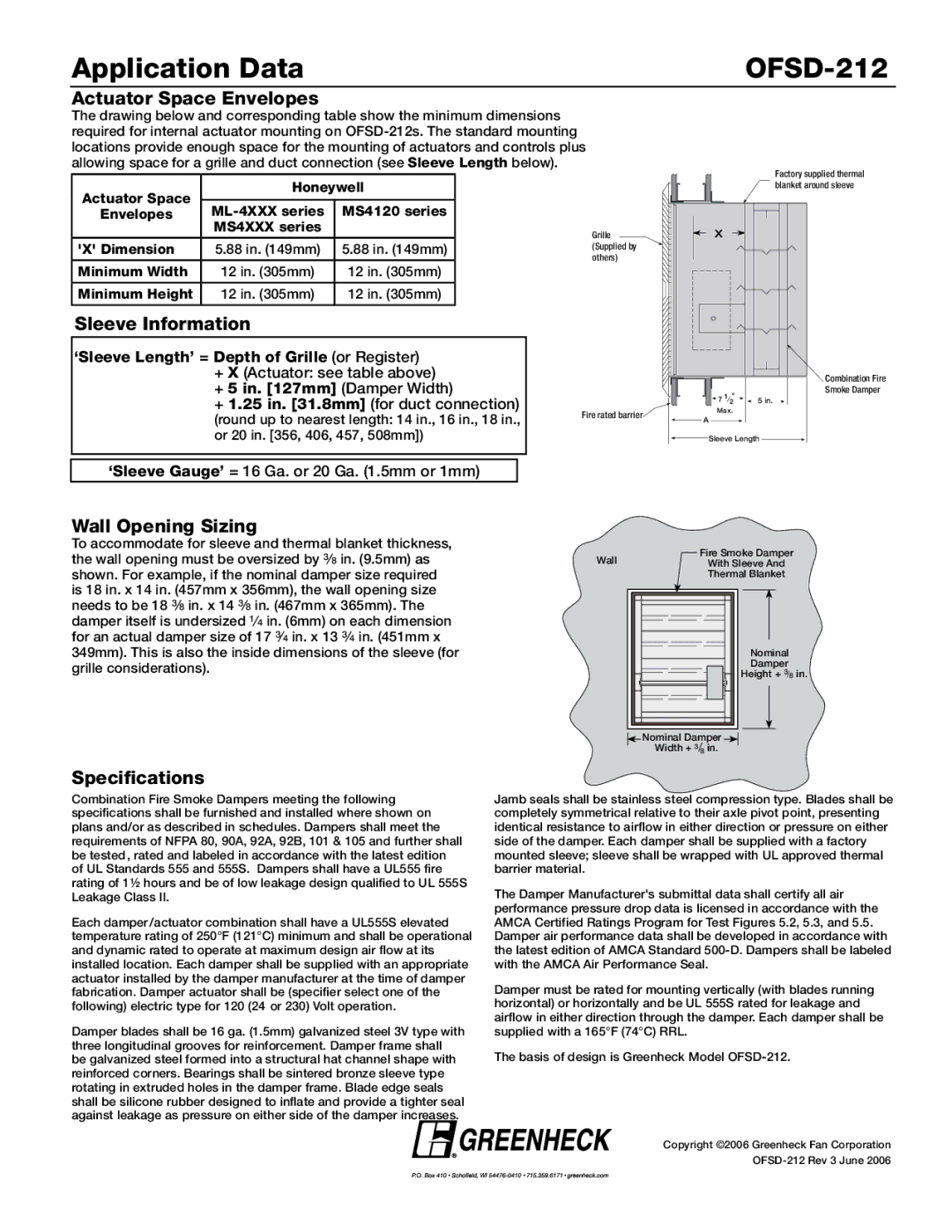

OFSD-212 specifications

The Greenheck Fan OFSD-212 is a high-performance, factory-built smoke and fire damper designed to provide dependable fire protection for commercial and industrial settings. Built with rigorous safety standards in mind, the OFSD-212 is engineered to ensure the containment of smoke and fire, thereby minimizing the risk of damage and injury during critical situations.One of the main features of the OFSD-212 is its robust construction. The damper is made from high-quality materials that can withstand extreme temperatures, which is vital for maintaining its integrity during a fire scenario. The frame is constructed from galvanized steel, providing durability and resistance against corrosion, while the blades are designed to close tightly to prevent smoke from passing through.

In terms of technology, the OFSD-212 incorporates advanced control mechanisms. It comes equipped with an electric actuator that ensures rapid closure of the damper when triggered by a fire alarm system. This feature allows for quick response times, which is crucial in limiting the spread of smoke and toxic gases within a building. Additionally, the actuator can be integrated with various fire alarm systems, providing flexibility in installations.

Another noteworthy characteristic of the OFSD-212 is its ease of installation and maintenance. The damper is designed with user-friendly features, allowing for straightforward installation in new construction or as a retrofit in existing facilities. With removable access panels, maintenance personnel can easily inspect and service the damper, ensuring it remains in optimal working condition.

The OFSD-212 is also designed with energy efficiency in mind. Its streamlined design limits airflow leakage, which not only enhances fire safety but also contributes to overall energy savings for the building. This energy efficiency aligns with modern building codes and standards, making it an excellent choice for developers and facility managers looking to create compliant and sustainable spaces.

In summary, the Greenheck Fan OFSD-212 is a notable solution for fire and smoke containment. Its robust construction, advanced technology, ease of installation, and energy efficiency make it a reliable choice for any commercial or industrial environment seeking to enhance safety and compliance.