Standard Construction

Housing

Tubular housings are constructed of welded steel to eliminate air leakage. Integral straightening vanes are constructed from steel and welded into place.

Wheel – Mixed Flow

Fabricated wheels are constructed from steel. The blade profiles are angled and contoured for the most efficient and quiet performance.

Bearings (Belt Drive)

Standard bearings are premium air handling quality, grease lubricated,

Bolted Access Door

A bolted access door provides an opening through the fan housing for cleaning or visual inspection of the wheel. A hinged access door is available as an accessory.

Belt Guard (Belt Drive)

A totally enclosed belt guard provides protection from rotating pulleys and belts. Belt guards meet OSHA Standards.

Slip-Fit Duct Connection (QEI-I/II & QEID)

Inlets and outlets are designed with extended collars for

Adjustable Motor Bases (Belt Drive)

Rigid,

Extended Lube Lines

Belt drive units have nylon lubrication lines with grease fittings that allow bearing lubrication without disassembling the fan. Grease fittings are mounted on the outside of the fan housing. Direct drive units have extended lubrication lines for the motor bearings, if required. Smaller frame sized motors are typically sealed and not lubricatable.

Permatector™ Coating

Greenheck’s Permatector coating is a thermosetting polyester urethane, electrostatically applied to provide uniform thickness and a clean appearance. Permatector coatings also provide excellent corrosion characteristics for general applications, both indoor and outdoor. For corrosive environments (ie. coastal), see page 9 for information on our zinc- rich basecoat technology.

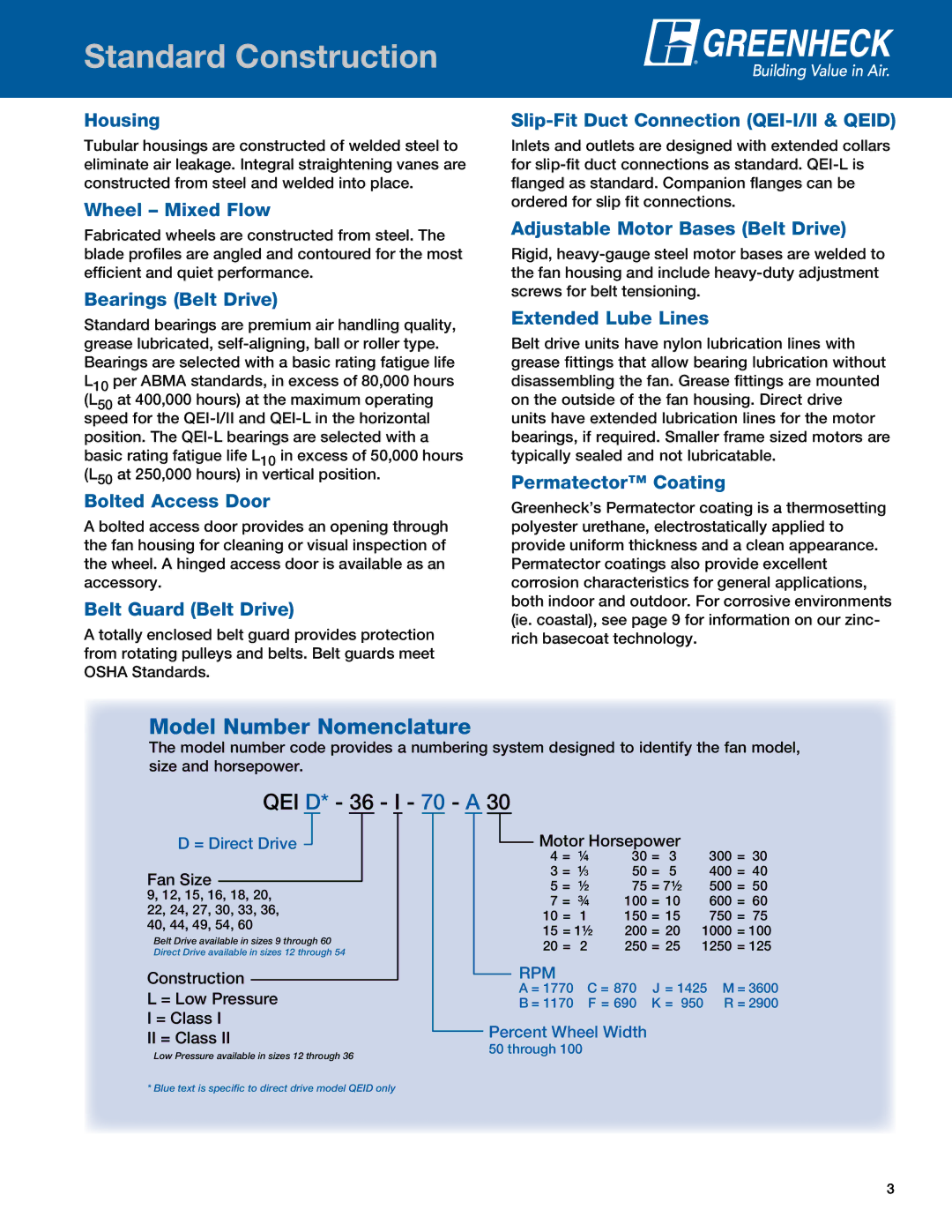

Model Number Nomenclature

The model number code provides a numbering system designed to identify the fan model, size and horsepower.

QEI D* - 36 - I - 70 - A 30

D = Direct Drive |

|

|

|

|

|

|

|

|

| Motor Horsepower | 300 | = 30 | ||||||

|

|

|

|

|

|

|

|

| ||||||||||

| ||||||||||||||||||

|

|

|

|

|

| 4 | = ¼ | 30 | = | 3 | ||||||||

Fan Size |

|

|

|

|

| 3 | = 3 | 50 | = | 5 | 400 | = 40 | ||||||

|

|

|

| 5 | = ½ | 75 | = 7½ | 500 | = 50 | |||||||||

|

|

|

| |||||||||||||||

9, 12, 15, 16, 18, 20, |

|

|

|

| ||||||||||||||

|

|

|

| 7 | = ¾ | 100 | = 10 | 600 | = 60 | |||||||||

22, 24, 27, 30, 33, 36, |

|

|

|

| ||||||||||||||

|

|

|

| 10 | = 1 | 150 | = 15 | 750 | = 75 | |||||||||

40, 44, 49, 54, 60 |

|

|

|

| ||||||||||||||

|

|

|

| 15 | = 1½ | 200 | = 20 | 1000 | = 100 | |||||||||

Belt Drive available in sizes 9 through 60 | ||||||||||||||||||

20 | = 2 | 250 | = 25 | 1250 | = 125 | |||||||||||||

Direct Drive available in sizes 12 through 54 | ||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

| |||||||

Construction |

|

|

|

|

| RPM |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| A = 1770 | C = 870 | J = 1425 | M = 3600 | |

L = Low Pressure |

|

|

|

| |||||

|

|

|

| B = 1170 | F = 690 | K = 950 | R = 2900 | ||

I = Class I |

|

|

| Percent Wheel Width |

|

| |||

II = Class II |

|

|

|

|

| ||||

|

|

|

|

| |||||

|

|

| 50 through 100 |

|

|

| |||

Low Pressure available in sizes 12 through 36 |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| ||

* Blue text is specific to direct drive model QEID only |

|

|

|

|

|

|

|

| |

3