Optional Two-coat

Paint System

In 1972, Greenheck took the lead as the first commercial and industrial fan manufacturer to introduce electrostatic powder coatings. Today, Greenheck continues to lead by being the first to offer a superior zinc-rich powder basecoat and powder coating finish.

This zinc-rich basecoat technology is used extensively outside the HVAC industry to protect bridge beams, automotive components and other heavy-gauge steel products. Now, this advanced technology is available on Greenheck welded steel products.

Greenheck’s coating process starts with a minimum of five wash stages to treat all components prior to painting. Cleaner parts result in better coating adhesion and durability. We then use an advanced two-coat powder application method that includes a basecoat of zinc-rich powder and a topcoat of Greenheck’s Permatector™ or Hi-Pro Polyester. The combination of these two topcoats over the zinc-rich basecoat results in the two-coatings, Perma-Z and Hi-Pro-Z. These oven-cured coatings provide superior corrosion resistance along with a tough, uniform finish to combat the most extreme conditions.

Zinc Advantage

When compared to a traditional single coat application, the benefits of the two-coat system include:

•An automatic powder coat application that produces uniform coverage and unmatched paint quality.

•A double coat thickness that provides superior durability and protection from air and water.

•A zinc-rich basecoat that includes an epoxy component that provides additional corrosion protection.

•A zinc-rich basecoat that provides chemical protection of exposed steel to prevent corrosion.

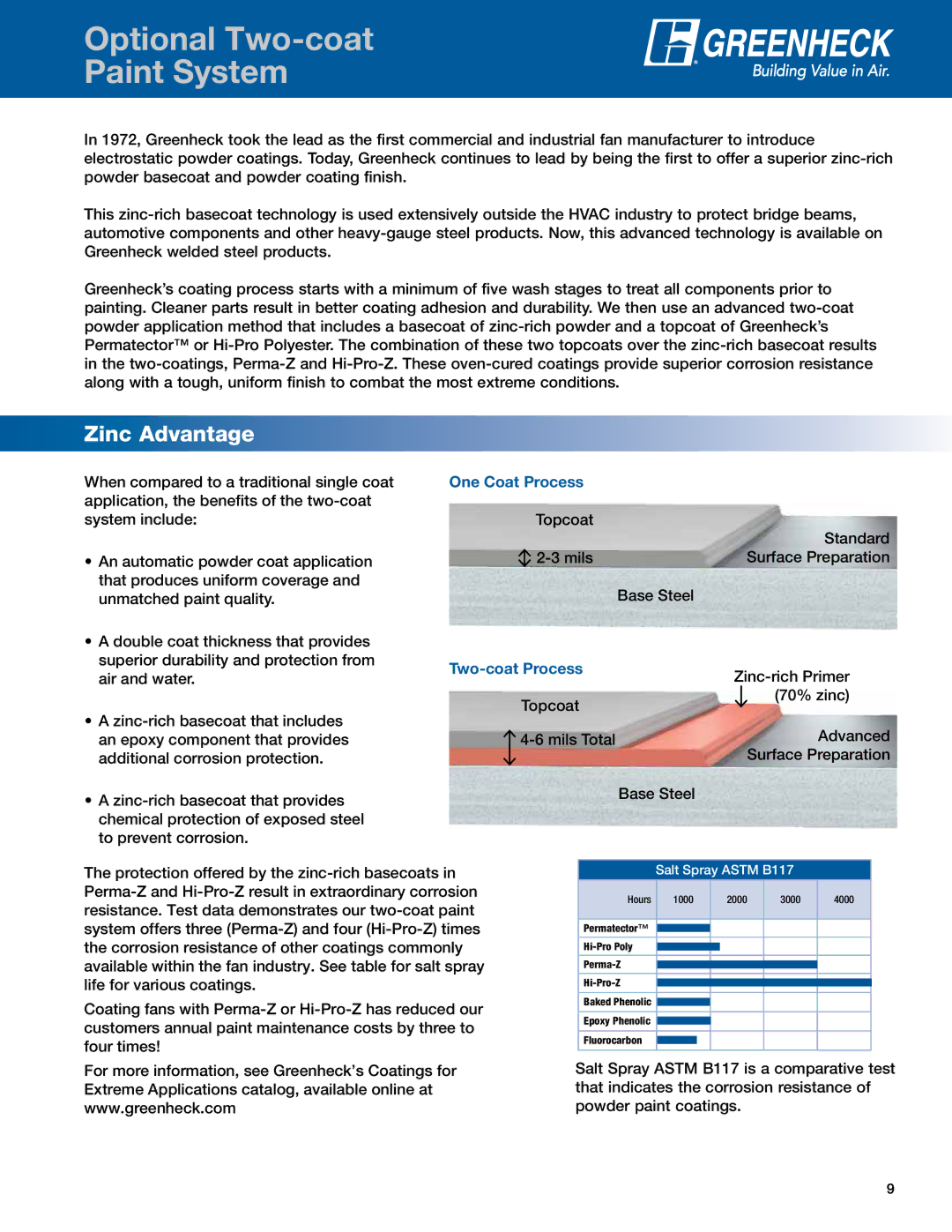

One Coat Process | | |

| | Topcoat | | |

| | | | Standard |

| | 2-3 mils | | Surface Preparation |

| |

| | | Base Steel |

Two-coat Process | Zinc-rich Primer |

| | |

| Topcoat | | (70% zinc) |

| | Advanced |

| 4-6 mils Total | |

|

| | | | Surface Preparation |

| | | Base Steel |

The protection offered by the zinc-rich basecoats in Perma-Z and Hi-Pro-Z result in extraordinary corrosion resistance. Test data demonstrates our two-coat paint system offers three (Perma-Z) and four (Hi-Pro-Z) times the corrosion resistance of other coatings commonly available within the fan industry. See table for salt spray life for various coatings.

Coating fans with Perma-Z or Hi-Pro-Z has reduced our customers annual paint maintenance costs by three to four times!

Salt Spray ASTM B117

Permatector™

Hi-Pro Poly

Perma-Z

Hi-Pro-Z

Baked Phenolic

Epoxy Phenolic

Fluorocarbon

For more information, see Greenheck’s Coatings for Extreme Applications catalog, available online at www.greenheck.com

Salt Spray ASTM B117 is a comparative test that indicates the corrosion resistance of powder paint coatings.