Installation Instructions

Greenheck’s IMO dampers were tested per the International Maritime Organization’s Fire Test Procedure (FTP) code in a Class A bulkhead and in a Class A deck for 60 minutes. The FTP code requires that the ductwork (coaming) be insulated and that the damper be bolted or welded to the duct.

1. Insulating the Duct

The ductwork must be insulated a minimum of 6 in. (152mm) on the damper side and 18 in. (457mm) on the

2. Attaching Damper to Duct

The damper can be installed to the duct using either bolts or welding. If bolts are used , they are to be a minimum of 0.375 in. (9.5mm) diameter and 1 in. (25mm) long. The fasteners should be spaced 6 in. (152mm) OC and a maximum of 2 in. (51mm) from the corners.

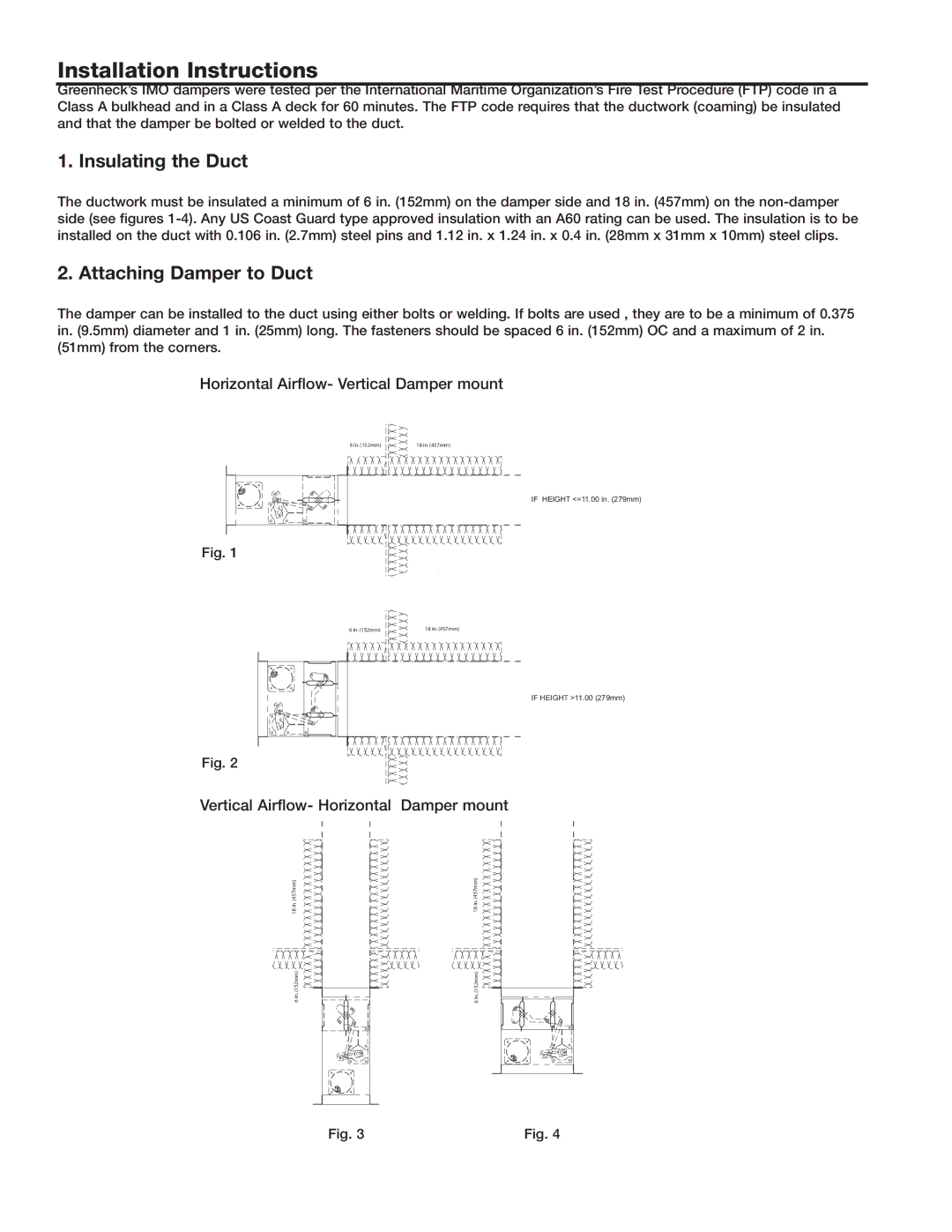

Horizontal Airflow- Vertical Damper mount

6 in. (152mm) | 18 in. (457mm) |

IF HEIGHT <=11.00 in. (279mm)

Fig. 1

6 in. (152mm) | 18 in. (457mm) |

IF HEIGHT >11.00 (279mm)

Fig. 2

Vertical Airflow- Horizontal Damper mount

18 in. (457mm)

6 in. (152mm)

6 in. (152mm)18 in. (457mm)

Fig. 3 | Fig. 4 |