Installation and Service Instructions | 53.20.10 |

For |

|

202CB and 204CD Series | May 1983 |

| |

General Purpose Solenoid Valve | Supd’s |

Safety Instructions

Attention: Read carefully before attempting to install, operate or service your Alco solenoid valve. Retain for future reference.

1.Read installation instructions - thoroughly. Failure to comply can result in valve failure or system damage or personal injury.

2.Do not use solenoid valves on applications or fluid media not specifically cataloged without prior approval of Alco Engineering Department.

WARNING: DO NOT USE WITH FLAMMABLE OR EXPLOSIVE FLUIDS OR GASES. DO NOT USE IN EXPLOSIVE ATMOSPHERES.

Use on these elements can result in product damage or personal injury.

3.Use of solenoid valves on applications not specifically cataloged can result in valve failure and/or system damage or personal injury. Do not utilize a solenoid valve on any system where the system pressure can exceed the safe working pressure of the valve.

4.CAUTION: Do not utilize a solenoid valve as a safety shut off.

5.Do not exceed MOPD (Maximum Operating Pressure Differential) or valve may fail to open when energized.

6.CAUTION: Always disconnect power source and depressurize the system before working on solenoid valve or system. If the power disconnect is

7.Direction of flow must correspond to Flow Direction Schematics.

8.Before energizing valve, be sure source voltage and frequency matches that on coil. Do not energize coil unless coil is securely attached to valve. See Coil Installation Instructions.

9.Prolonged use in excessive ambient temperature or humidity may damage coils.

10.Do not dent or bend or use enclosing tube as lever. A damaged enclosing tube may result in coil burnout or inoperative valve.

11.Foreign matter in the valve may result in seal leakage, sticking open or closed, or coil burnout. To prolong valve life and ensure system cleanliness use a strainer

Installation

Valve and Solenoid Position

1.For ease of installation, an Alco solenoid valve can be installed in any position. Gravity does not affect its operation.

NOTE: Although all valves can be operated in any position, by mounting the valve upright there is less chance of malfunction caused by the collection of foreign material

2. The solenoid coil can be rotated 360O for ease of wiring. If possible do not reduce the length of the solenoid coil wire leads, so that if it becomes necessary to remove coil at a later date (for valve cleanout, etc.) wire leads will not have to be disconnected.

3.To allow for removal of the solenoid coil without removing the valve from its piping, allow at least 2 inches of clearance above the solenoid.

4.Be sure valve is installed so that its flow arrow on valve body corresponds to direction of flow thru piping.

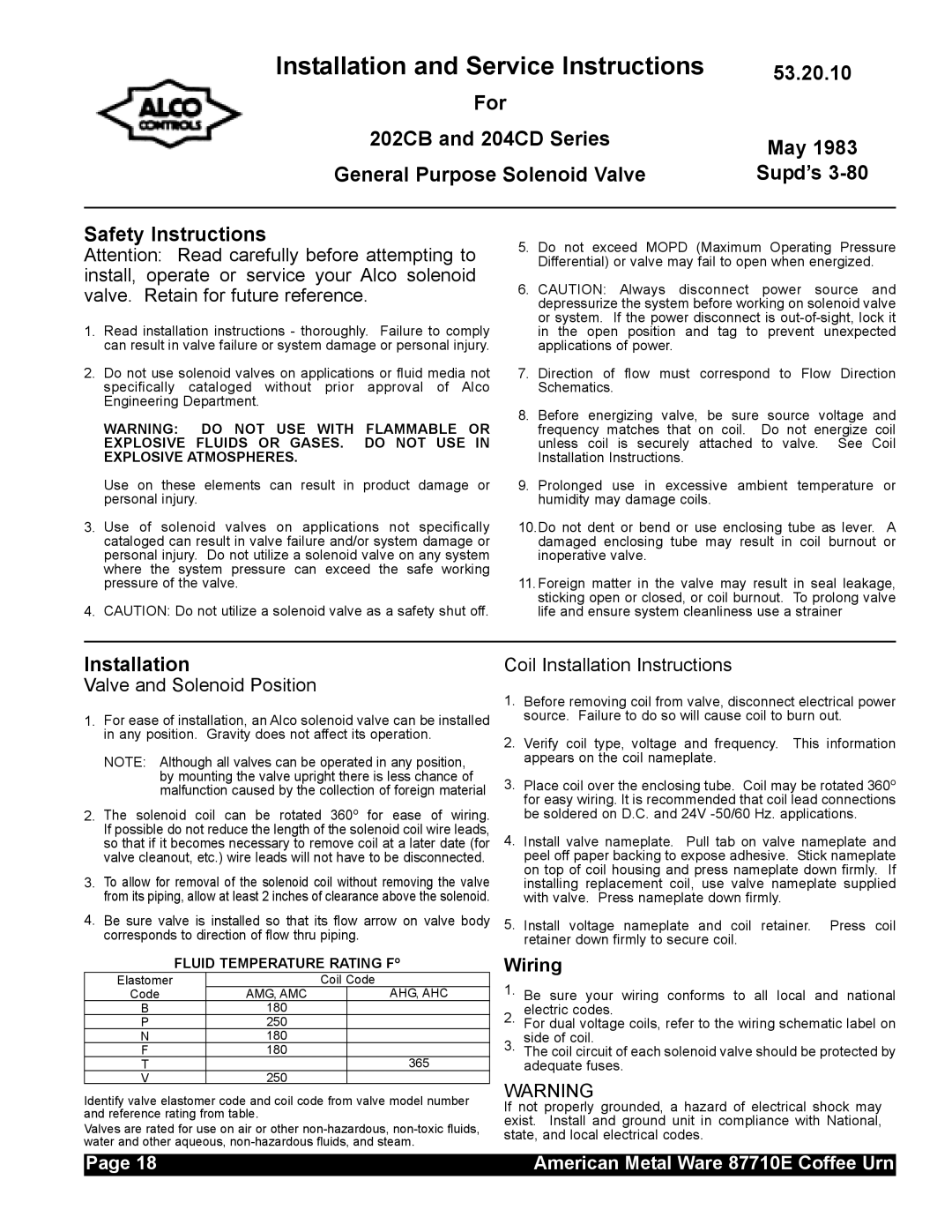

FLUID TEMPERATURE RATING FO

Elastomer |

| Coil Code | |

Code | AMG, AMC |

| AHG, AHC |

B | 180 |

|

|

P | 250 |

|

|

N | 180 |

|

|

F | 180 |

|

|

T |

|

| 365 |

V | 250 |

|

|

Identify valve elastomer code and coil code from valve model number and reference rating from table.

Valves are rated for use on air or other

Coil Installation Instructions

1.Before removing coil from valve, disconnect electrical power source. Failure to do so will cause coil to burn out.

2.Verify coil type, voltage and frequency. This information appears on the coil nameplate.

3.Place coil over the enclosing tube. Coil may be rotated 360O for easy wiring. It is recommended that coil lead connections be soldered on D.C. and 24V

4.Install valve nameplate. Pull tab on valve nameplate and peel off paper backing to expose adhesive. Stick nameplate on top of coil housing and press nameplate down firmly. If installing replacement coil, use valve nameplate supplied with valve. Press nameplate down firmly.

5.Install voltage nameplate and coil retainer. Press coil retainer down firmly to secure coil.

Wiring

1.Be sure your wiring conforms to all local and national electric codes.

2.For dual voltage coils, refer to the wiring schematic label on side of coil.

3.The coil circuit of each solenoid valve should be protected by adequate fuses.

WARNING

If not properly grounded, a hazard of electrical shock may exist. Install and ground unit in compliance with National, state, and local electrical codes.

|

|

Page 18 | American Metal Ware 87710E Coffee Urn |