SECTION 6: MAINTENANCE

General

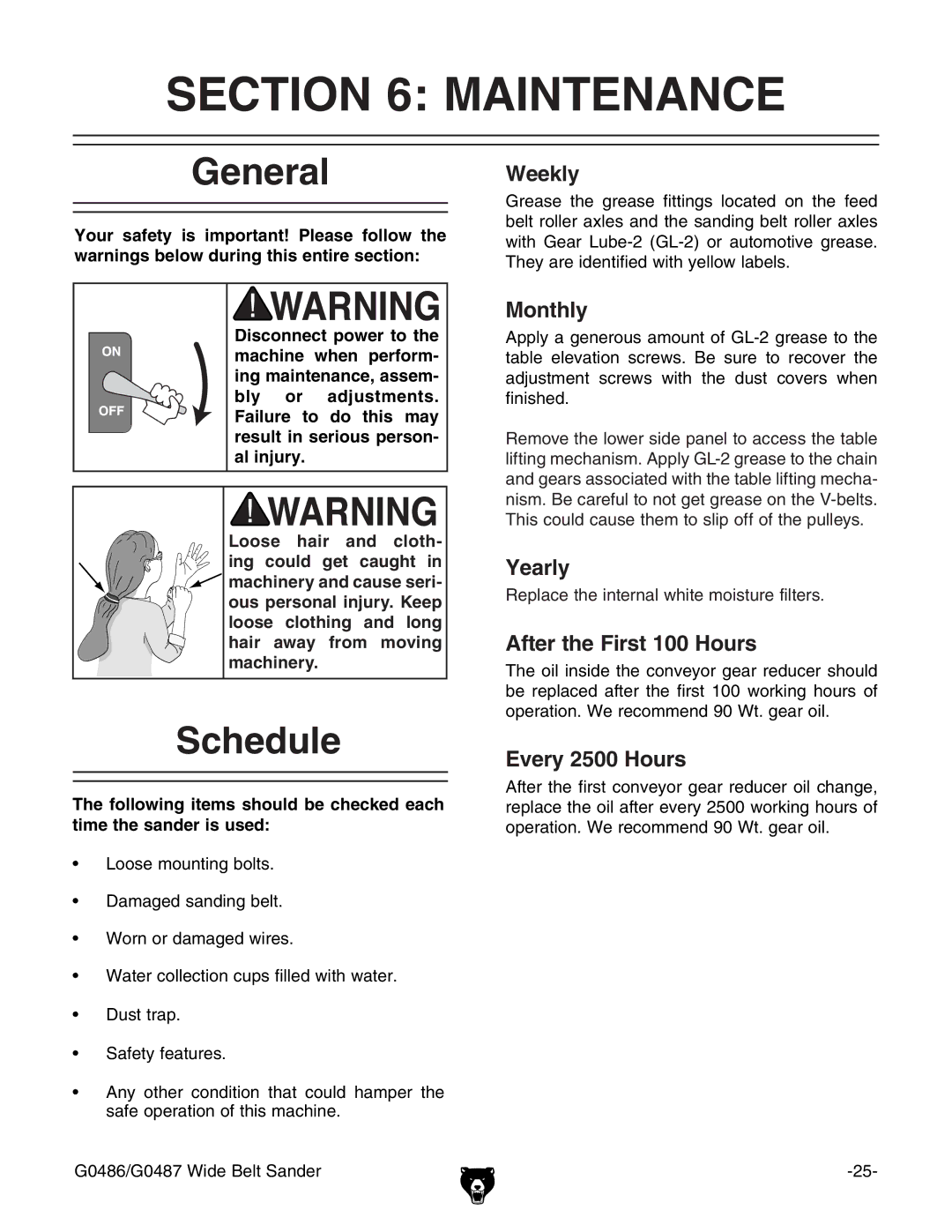

Your safety is important! Please follow the warnings below during this entire section:

Disconnect power to the machine when perform- ing maintenance, assem- bly or adjustments. Failure to do this may result in serious person- al injury.

Loose hair and cloth-

ing could get caught in

![]() machinery and cause seri-

machinery and cause seri-

ous personal injury. Keep

loose clothing and long

hair away from moving machinery.

Schedule

The following items should be checked each time the sander is used:

•Loose mounting bolts.

•Damaged sanding belt.

•Worn or damaged wires.

•Water collection cups filled with water.

•Dust trap.

•Safety features.

•Any other condition that could hamper the safe operation of this machine.

G0486/G0487 Wide Belt Sander

Weekly

Grease the grease fittings located on the feed belt roller axles and the sanding belt roller axles with Gear

Monthly

Apply a generous amount of

Remove the lower side panel to access the table lifting mechanism. Apply

Yearly

Replace the internal white moisture filters.

After the First 100 Hours

The oil inside the conveyor gear reducer should be replaced after the first 100 working hours of operation. We recommend 90 Wt. gear oil.

Every 2500 Hours

After the first conveyor gear reducer oil change, replace the oil after every 2500 working hours of operation. We recommend 90 Wt. gear oil.