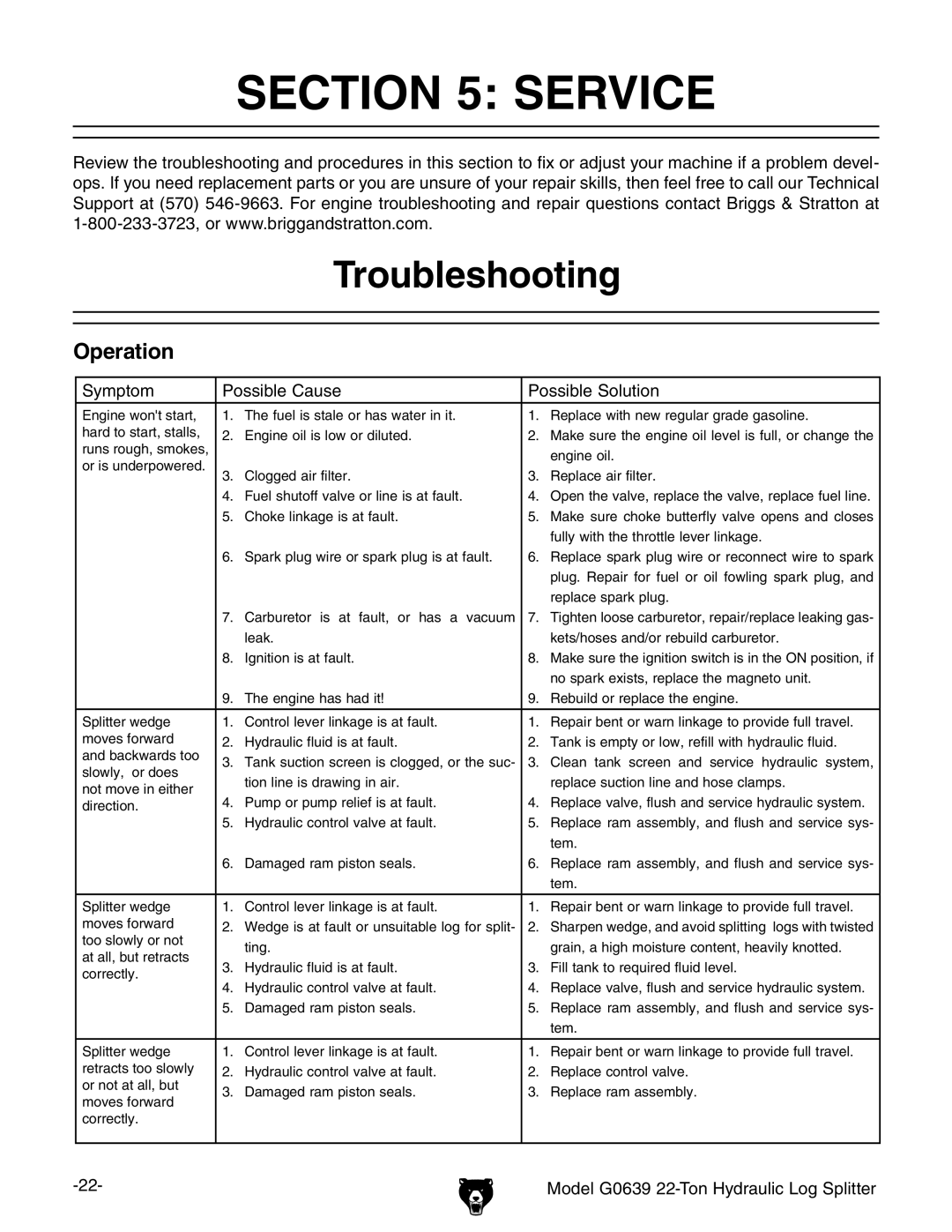

SECTION 5: SERVICE

Review the troubleshooting and procedures in this section to fix or adjust your machine if a problem devel- ops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support at (570)

Troubleshooting

Operation Tshooting

| Symptom | Possible Cause | Possible Solution | ||

|

|

|

|

|

|

| Engine won't start, | 1. | The fuel is stale or has water in it. | 1. | Replace with new regular grade gasoline. |

| hard to start, stalls, | 2. | Engine oil is low or diluted. | 2. | Make sure the engine oil level is full, or change the |

| runs rough, smokes, |

|

|

| engine oil. |

| or is underpowered. |

|

|

| |

| 3. | Clogged air filter. | 3. | Replace air filter. | |

|

| ||||

|

| 4. | Fuel shutoff valve or line is at fault. | 4. | Open the valve, replace the valve, replace fuel line. |

|

| 5. | Choke linkage is at fault. | 5. | Make sure choke butterfly valve opens and closes |

|

|

|

|

| fully with the throttle lever linkage. |

|

| 6. | Spark plug wire or spark plug is at fault. | 6. | Replace spark plug wire or reconnect wire to spark |

|

|

|

|

| plug. Repair for fuel or oil fowling spark plug, and |

|

|

|

|

| replace spark plug. |

|

| 7. | Carburetor is at fault, or has a vacuum | 7. | Tighten loose carburetor, repair/replace leaking gas- |

|

|

| leak. |

| kets/hoses and/or rebuild carburetor. |

|

| 8. | Ignition is at fault. | 8. | Make sure the ignition switch is in the ON position, if |

|

|

|

|

| no spark exists, replace the magneto unit. |

|

| 9. | The engine has had it! | 9. | Rebuild or replace the engine. |

|

|

|

|

|

|

| Splitter wedge | 1. | Control lever linkage is at fault. | 1. | Repair bent or warn linkage to provide full travel. |

| moves forward | 2. | Hydraulic fluid is at fault. | 2. | Tank is empty or low, refill with hydraulic fluid. |

| and backwards too | 3. | Tank suction screen is clogged, or the suc- | 3. | Clean tank screen and service hydraulic system, |

| slowly, or does | ||||

|

| tion line is drawing in air. |

| replace suction line and hose clamps. | |

| not move in either |

|

| ||

| 4. | Pump or pump relief is at fault. | 4. | Replace valve, flush and service hydraulic system. | |

| direction. | ||||

|

| 5. | Hydraulic control valve at fault. | 5. | Replace ram assembly, and flush and service sys- |

|

|

|

|

| tem. |

|

| 6. | Damaged ram piston seals. | 6. | Replace ram assembly, and flush and service sys- |

|

|

|

|

| tem. |

|

|

|

|

|

|

| Splitter wedge | 1. | Control lever linkage is at fault. | 1. | Repair bent or warn linkage to provide full travel. |

| moves forward | 2. | Wedge is at fault or unsuitable log for split- | 2. | Sharpen wedge, and avoid splitting logs with twisted |

| too slowly or not |

| ting. |

| grain, a high moisture content, heavily knotted. |

| at all, but retracts |

|

| ||

| 3. | Hydraulic fluid is at fault. | 3. | Fill tank to required fluid level. | |

| correctly. | ||||

| 4. | Hydraulic control valve at fault. | 4. | Replace valve, flush and service hydraulic system. | |

|

| ||||

|

| 5. | Damaged ram piston seals. | 5. | Replace ram assembly, and flush and service sys- |

|

|

|

|

| tem. |

|

|

|

|

|

|

| Splitter wedge | 1. | Control lever linkage is at fault. | 1. | Repair bent or warn linkage to provide full travel. |

| retracts too slowly | 2. | Hydraulic control valve at fault. | 2. | Replace control valve. |

| or not at all, but | 3. | Damaged ram piston seals. | 3. | Replace ram assembly. |

| moves forward | ||||

|

|

|

|

| |

| correctly. |

|

|

|

|

|

|

|

|

|

|

|

|

| Model G0639 | ||