tensioning & tracking

Conveyor Belt

Tensioning

The conveyor belt may stretch with extended use, causing it to slip on the conveyor rollers. If this happens, the conveyor belt will need to be reten- sioned.

When you tension the conveyor belt, make sure you turn the left and right adjustment bolts in even increments. Tensioning one side more than the other will cause tracking problems, which will require you to take additional steps to get the sander operating correctly.

To tension the conveyor belt:

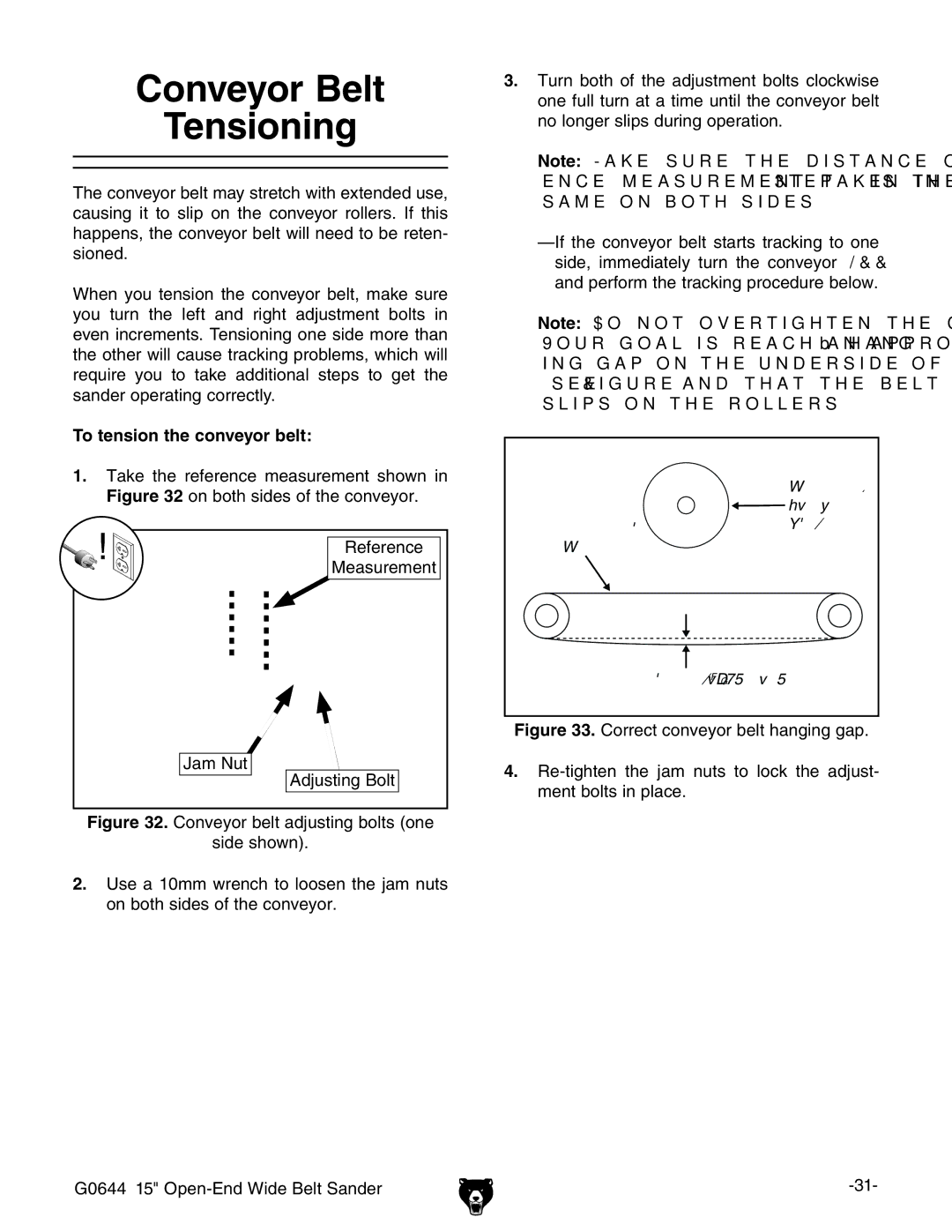

1.Take the reference measurement shown in Figure 32 on both sides of the conveyor.

Reference |

Measurement |

Jam Nut |

Adjusting Bolt |

Figure 32. Conveyor belt adjusting bolts (one

side shown).

2.Use a 10mm wrench to loosen the jam nuts on both sides of the conveyor.

G0644 15" Open-End Wide Belt Sander

3.Turn both of the adjustment bolts clockwise one full turn at a time until the conveyor belt no longer slips during operation.

Note: Make sure the distance of the refer- ence measurement taken in Step 1 is the same on both sides.

—If the conveyor belt starts tracking to one side, immediately turn the conveyor OFF and perform the tracking procedure below.

Note: Do not overtighten the conveyor belt. Your goal is reach an approximate 1⁄2" hang- ing gap on the underside of the conveyor belt (see Figure 33) and that the belt no longer slips on the rollers.

| ������ |

| ������� |

�������� | ���� |

| |

���� |

|

����������������������