lubrication

SECTION 6: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, follow this maintenance schedule and refer to any specific instructions given in this section.

Daily:

•Check/tighten loose mounting bolts.

•Check/replace damaged or worn sanding belt.

•Check and repair/replace worn or damaged wires.

•Check/resolve any other unsafe condition.

Bi-Monthly:

•Check/lubricate elevation dovetail way.

•Check/lubricate Elevation gear.

•Check/empty air regulator filter reservoir.

Cleaning

Vacuum excess sawdust, and wipe off the remain- ing dust with a dry cloth.

Use warm soapy water to clean the conveyor belt. DO NOT use corrosive or

Extend the life of the sandpaper by regular- ly using a

Lubrication

The bearings are factory lubricated and sealed and require no further lubrication. Simply leave them alone unless they need replacement.

The devices that do require lubrication are the elevation dovetail way and gears. Keep these devices adequately lubricated so that elevation adjustments move smoothly.

To lubricate the elevation gibs:

1.DISCONNECT THE SANDER FROM POWER!

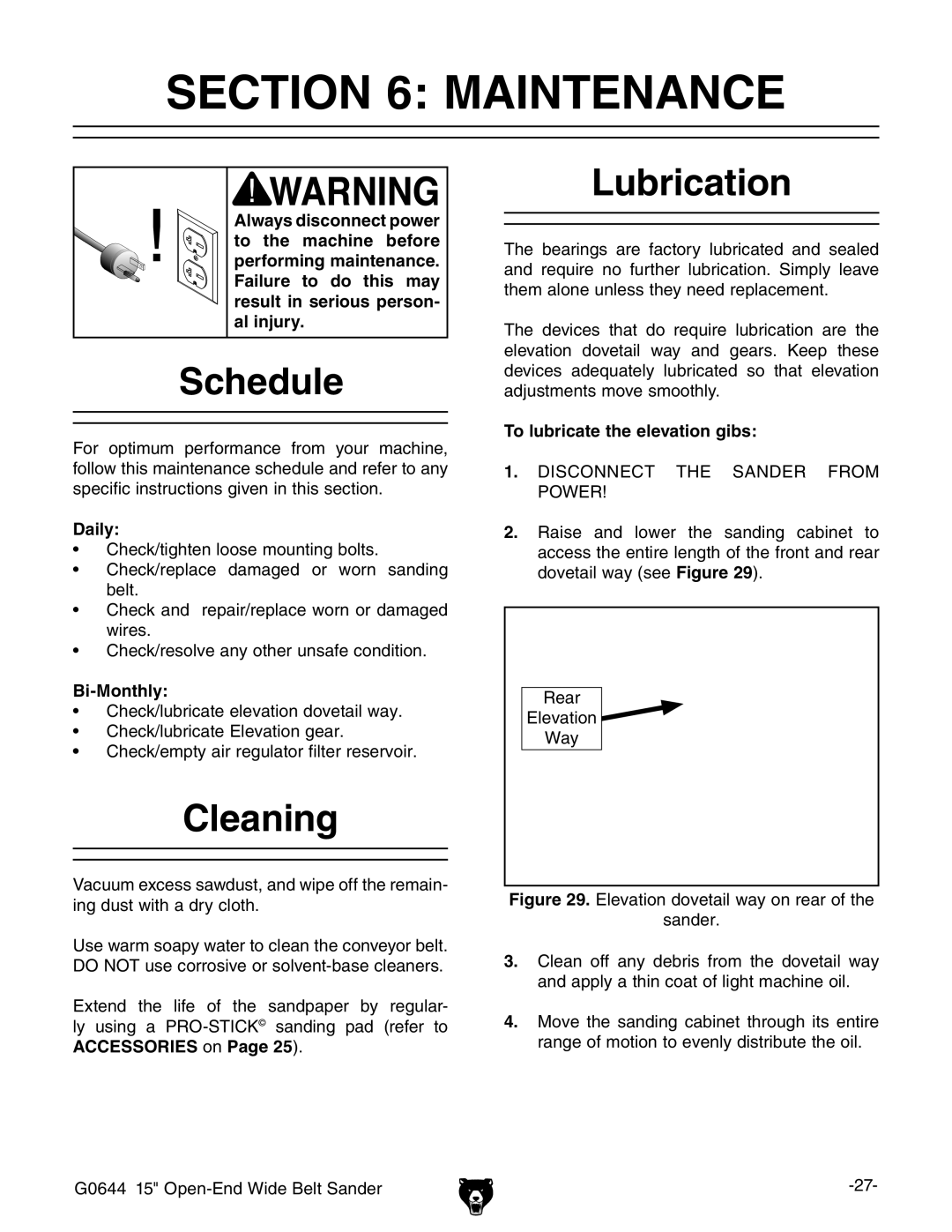

2.Raise and lower the sanding cabinet to access the entire length of the front and rear dovetail way (see Figure 29).

Rear

Elevation ![]()

Way

Figure 29. Elevation dovetail way on rear of the

sander.

3.Clean off any debris from the dovetail way and apply a thin coat of light machine oil.

4.Move the sanding cabinet through its entire range of motion to evenly distribute the oil.

G0644 15" |