MAINTENANCE

The life span of the machine can be reduced and the risk of accidents can increase if machine maintenance is not carried out correctly and if service and/or repairs are not carried out professionally. If you need further information, please contact your nearest authorised service dealer.

Carburetor

Your Jonsered product has been designed and manufactured to specifications that re- duce harmful emissions. After the engine has used

WARNING: The complete clutch, clutch cover, and shaft must be fitted before the machine is started, otherwise parts could come loose and cause personal injury.

Function

SThe carburetor governs the engine’s speed via the throttle control. Air and fuel

are mixed in the carburetor.

SThe

Basic setting

SThe basic carburetor settings are ad- justed during testing at the factory. Fine adjustment should be carried out by a skilled technician.

WARNING: The cutting attach- ment may be spinning during carbu- retor adjustments. Wear your protec- tive equipment and observe all safe- ty instructions. Be sure the cutting attachment stops turning when the engine idles. When the unit is turned off, make sure the cutting attach- ments has stopped before the unit is set down.

CAUTION! If the cutting attachment rotates when the engine is idling the idle adjustment screw T should be turned counterclockwise until the cutting attachment stops.

Rec. idle speed:

See “Technical data” section.

Recommended max. speed:

See “Technical data” section.

Fine adjustment of the idle speed-T

Adjust the idle speed using the idle adjust- ment

Idle Speed

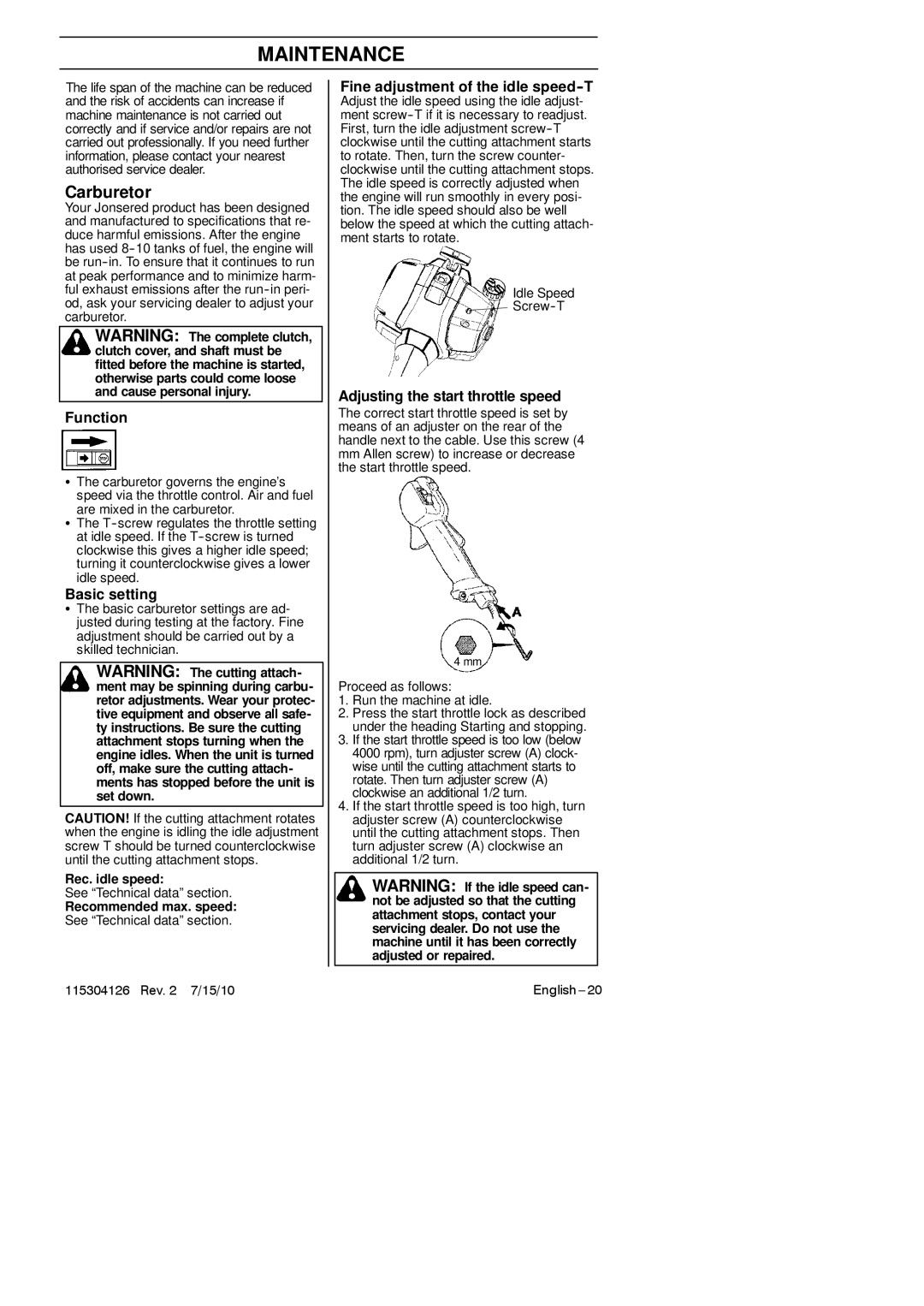

Adjusting the start throttle speed

The correct start throttle speed is set by means of an adjuster on the rear of the handle next to the cable. Use this screw (4

mmAllen screw) to increase or decrease the start throttle speed.

4 mm

Proceed as follows:

1.Run the machine at idle.

2.Press the start throttle lock as described under the heading Starting and stopping.

3.If the start throttle speed is too low (below 4000 rpm), turn adjuster screw (A) clock- wise until the cutting attachment starts to rotate. Then turn adjuster screw (A) clockwise an additional 1/2 turn.

4.If the start throttle speed is too high, turn adjuster screw (A) counterclockwise until the cutting attachment stops. Then turn adjuster screw (A) clockwise an additional 1/2 turn.

WARNING: If the idle speed can- not be adjusted so that the cutting attachment stops, contact your servicing dealer. Do not use the machine until it has been correctly adjusted or repaired.

115304126 Rev. 2 7/15/10 |