SECTION 6: MAINTENANCE

Always disconnect power to the machine before performing maintenance. Failure to do this may result in serious person- al injury.

Schedule

For optimum performance from your machine, fol- low this maintenance schedule:

Daily

•Check/correct loose hardware.

•Check/correct damaged knives.

•Check/correct worn or damaged wires.

•Correct any other unsafe condition.

•Lubricate elevation screws, elevation lock cams, columns, and feed roller chain drive.

Monthly

•Check for belt tension, damage, or wear.

•Remove cutterhead guard and thoroughly clean all

Cleaning

Vacuum excess wood chips and sawdust, and wipe off the remaining dust with a dry cloth. If resin has built up, use a resin dissolving cleaner to remove it.

Lubrication

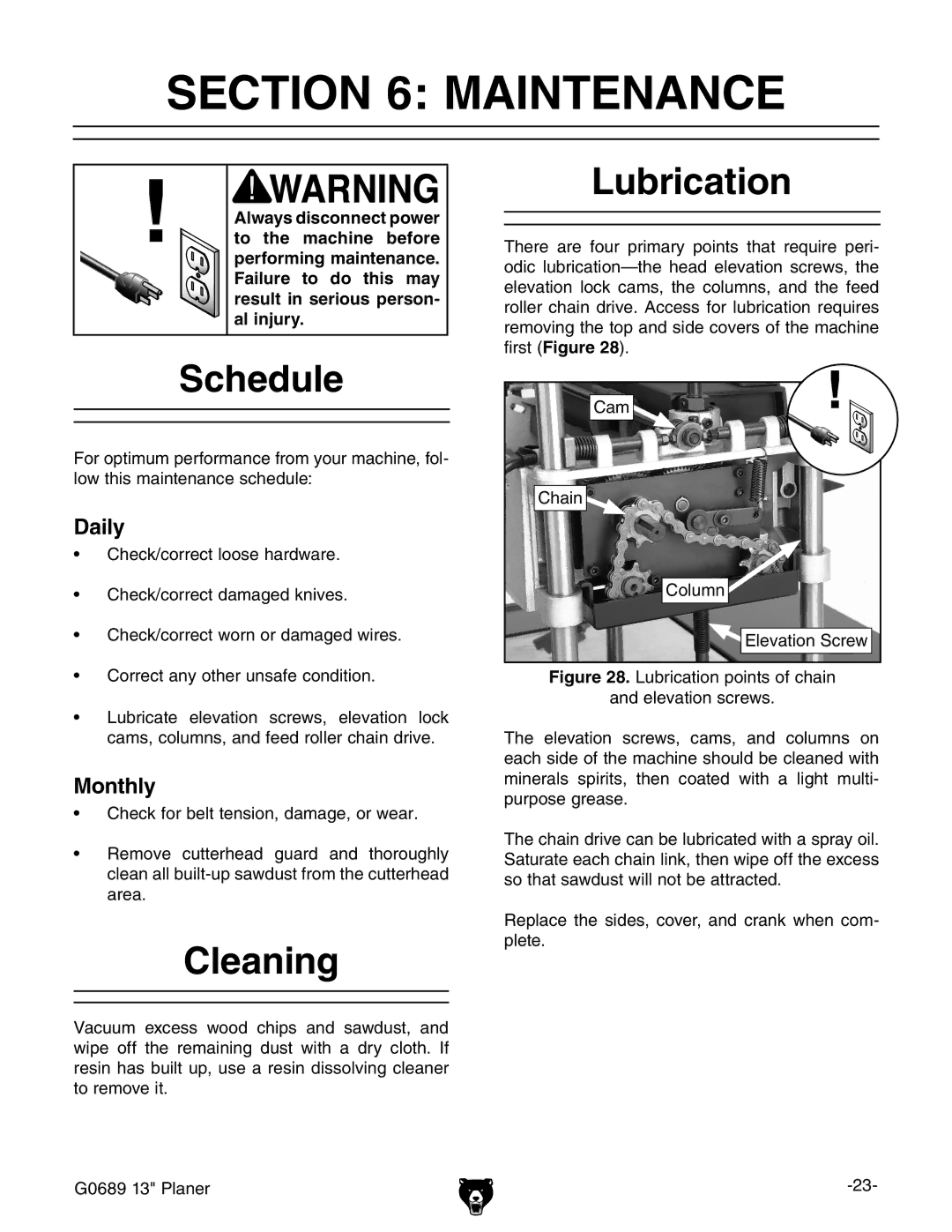

There are four primary points that require peri- odic

Cam |

Chain |

Column |

Elevation Screw |

Figure 28. Lubrication points of chain

and elevation screws.

The elevation screws, cams, and columns on each side of the machine should be cleaned with minerals spirits, then coated with a light multi- purpose grease.

The chain drive can be lubricated with a spray oil. Saturate each chain link, then wipe off the excess so that sawdust will not be attracted.

Replace the sides, cover, and crank when com- plete.

G0689 13" Planer |