Scale Calibration

Tools Needed: | Qty |

Phillips Head Screwdriver #2 | ............................. 1 |

Calipers | 1 |

The scale can be adjusted for accuracy. The machine will need to be run to make proper adjustments.

To calibrate the scale:

1.Set the table to the approximate thickness of your test lumber. Measure the lumber with calipers to determine its exact thickness.

2.Move the table to 1⁄16'' under the thickness of your lumber and feed your test board through the planer.

3.Turn the handwheel one full rotation and run the board through once more. Turn the board over and repeat.

4.

Figure 39. Depth scale adjustment screws.

Model G1033X (Mfg. since 4/10)

Anti-Kickback Fingers

The Model G1033X provides an

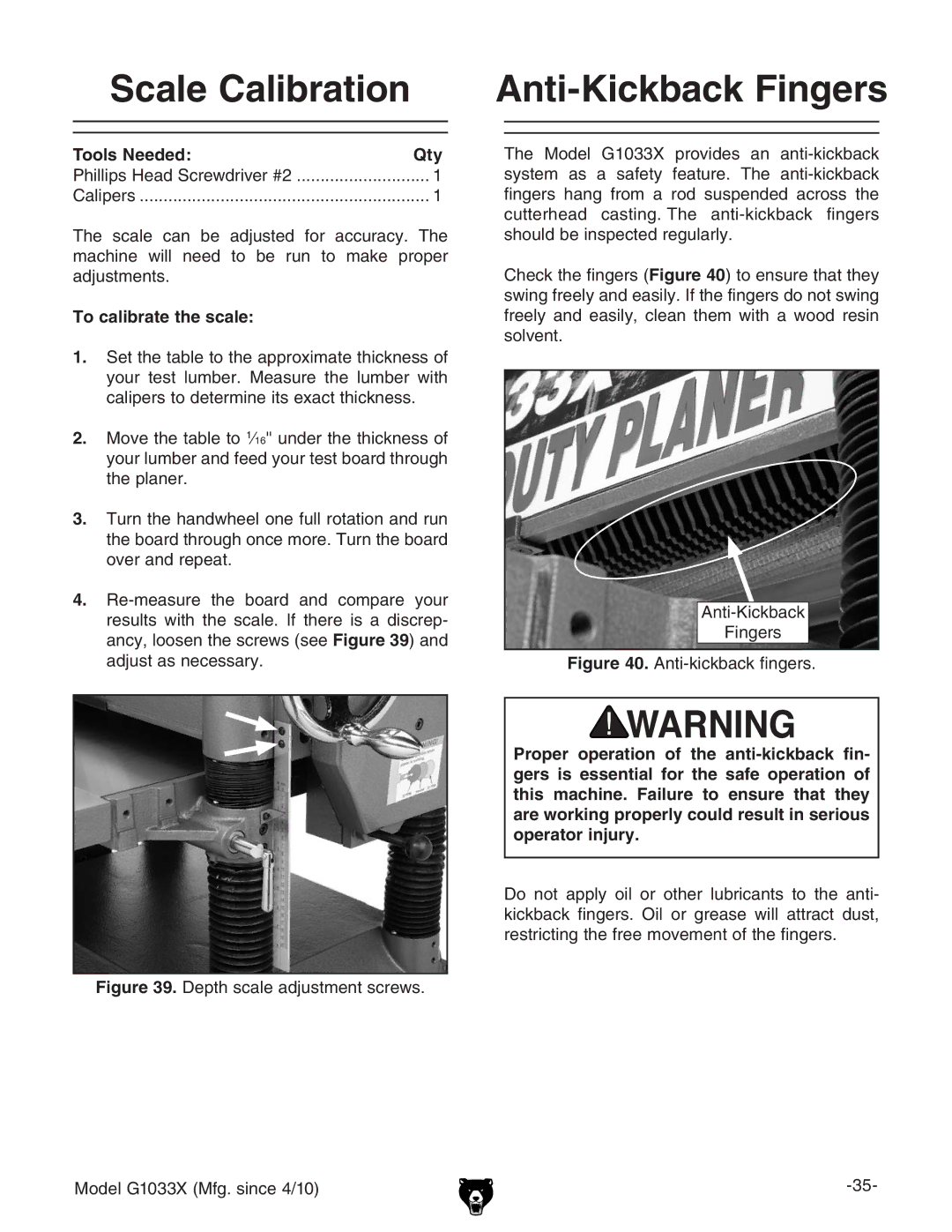

Check the fingers (Figure 40) to ensure that they swing freely and easily. If the fingers do not swing freely and easily, clean them with a wood resin solvent.

Fingers

Figure 40. Anti-kickback fingers.

Proper operation of the

Do not apply oil or other lubricants to the anti- kickback fingers. Oil or grease will attract dust, restricting the free movement of the fingers.