SECTION 7: SERVICE

Review the troubleshooting and procedures in this section to fix your machine if a problem develops. If you need replacement parts or you are unsure of your repair skills, then feel free to call our Technical Support at (570)

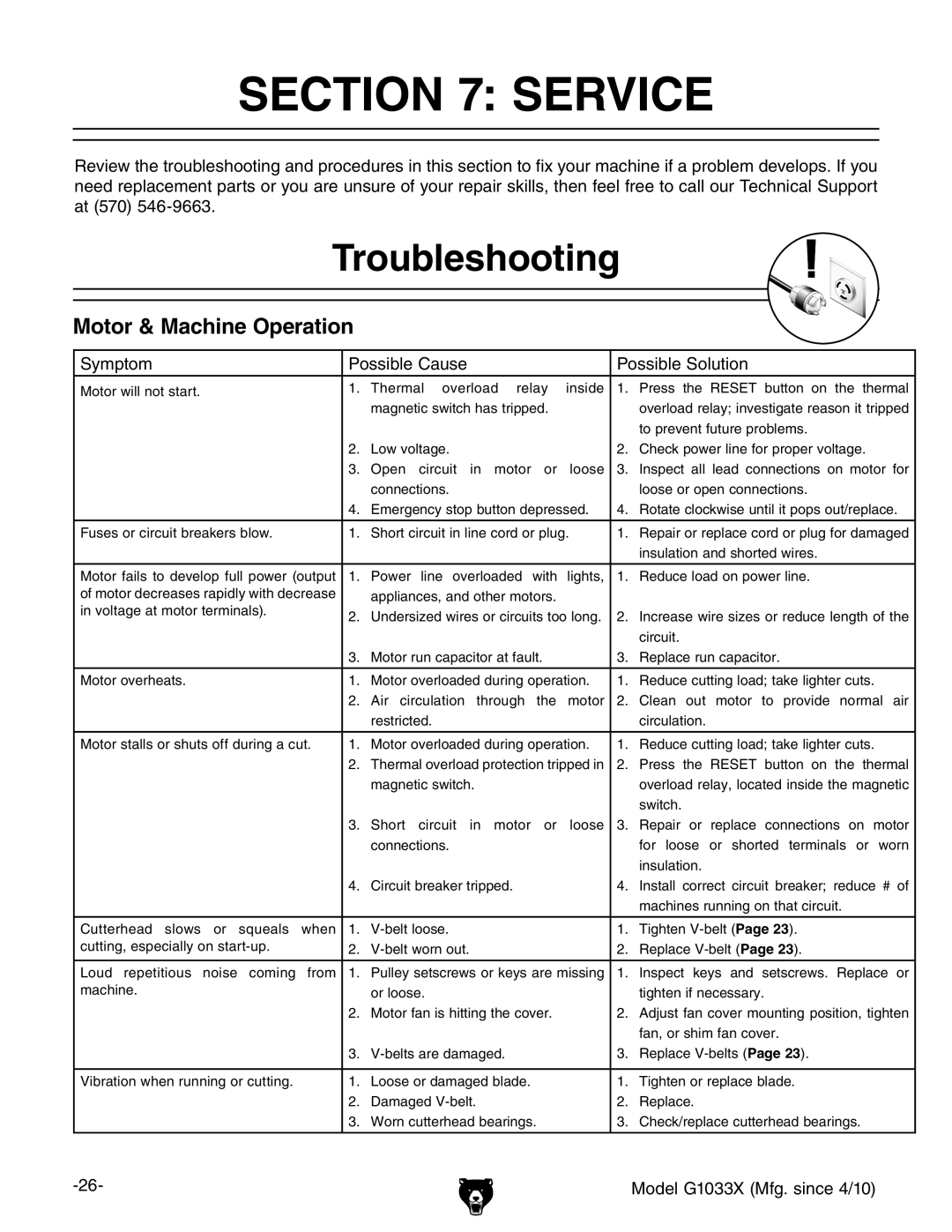

Troubleshooting

Motor & Machine Operation

Symptom | Possible Cause | Possible Solution | ||

Motor will not start. | 1. | Thermal overload relay inside | 1. | Press the RESET button on the thermal |

|

| magnetic switch has tripped. |

| overload relay; investigate reason it tripped |

|

|

|

| to prevent future problems. |

| 2. | Low voltage. | 2. | Check power line for proper voltage. |

| 3. | Open circuit in motor or loose | 3. | Inspect all lead connections on motor for |

|

| connections. |

| loose or open connections. |

| 4. | Emergency stop button depressed. | 4. | Rotate clockwise until it pops out/replace. |

|

|

|

|

|

Fuses or circuit breakers blow. | 1. | Short circuit in line cord or plug. | 1. | Repair or replace cord or plug for damaged |

|

|

|

| insulation and shorted wires. |

|

|

|

|

|

Motor fails to develop full power (output | 1. | Power line overloaded with lights, | 1. | Reduce load on power line. |

of motor decreases rapidly with decrease |

| appliances, and other motors. |

|

|

in voltage at motor terminals). | 2. | Undersized wires or circuits too long. | 2. | Increase wire sizes or reduce length of the |

| ||||

|

|

|

| circuit. |

| 3. | Motor run capacitor at fault. | 3. | Replace run capacitor. |

|

|

|

|

|

Motor overheats. | 1. | Motor overloaded during operation. | 1. | Reduce cutting load; take lighter cuts. |

| 2. | Air circulation through the motor | 2. | Clean out motor to provide normal air |

|

| restricted. |

| circulation. |

|

|

|

|

|

Motor stalls or shuts off during a cut. | 1. | Motor overloaded during operation. | 1. | Reduce cutting load; take lighter cuts. |

| 2. | Thermal overload protection tripped in | 2. | Press the RESET button on the thermal |

|

| magnetic switch. |

| overload relay, located inside the magnetic |

|

|

|

| switch. |

| 3. | Short circuit in motor or loose | 3. | Repair or replace connections on motor |

|

| connections. |

| for loose or shorted terminals or worn |

|

|

|

| insulation. |

| 4. | Circuit breaker tripped. | 4. | Install correct circuit breaker; reduce # of |

|

|

|

| machines running on that circuit. |

|

|

|

|

|

Cutterhead slows or squeals when | 1. | 1. | Tighten | |

cutting, especially on | 2. | 2. | Replace | |

|

|

|

|

|

Loud repetitious noise coming from | 1. | Pulley setscrews or keys are missing | 1. | Inspect keys and setscrews. Replace or |

machine. |

| or loose. |

| tighten if necessary. |

| 2. | Motor fan is hitting the cover. | 2. | Adjust fan cover mounting position, tighten |

|

|

|

| fan, or shim fan cover. |

| 3. | 3. | Replace | |

|

|

|

|

|

Vibration when running or cutting. | 1. | Loose or damaged blade. | 1. | Tighten or replace blade. |

| 2. | Damaged | 2. | Replace. |

| 3. | Worn cutterhead bearings. | 3. | Check/replace cutterhead bearings. |

|

|

|

|

|

|

|

| Model G1033X (Mfg. since 4/10) | |