2.Make sure the cutters are set correctly.

3.Lower the table at least 4" below the head casting and lock the table in place.

4.Remove the dust port, top cover, and belt cover.

5.Using your Rotacator, find BDC of any carbide insert edge by slowly rocking the cutterhead pulley back and forth, and set the Rotacator dial to zero, as shown in Figure 32.

Figure 32. Finding BDC with the Rotacator.

6.Place the Rotacator under the right-hand side of the infeed roller and find bottom dead center on a serrated edge by sliding the Rotacator right to left in a zigzag pat- tern—toward the infeed extension wing, then toward the outfeed extension wing, and so on.

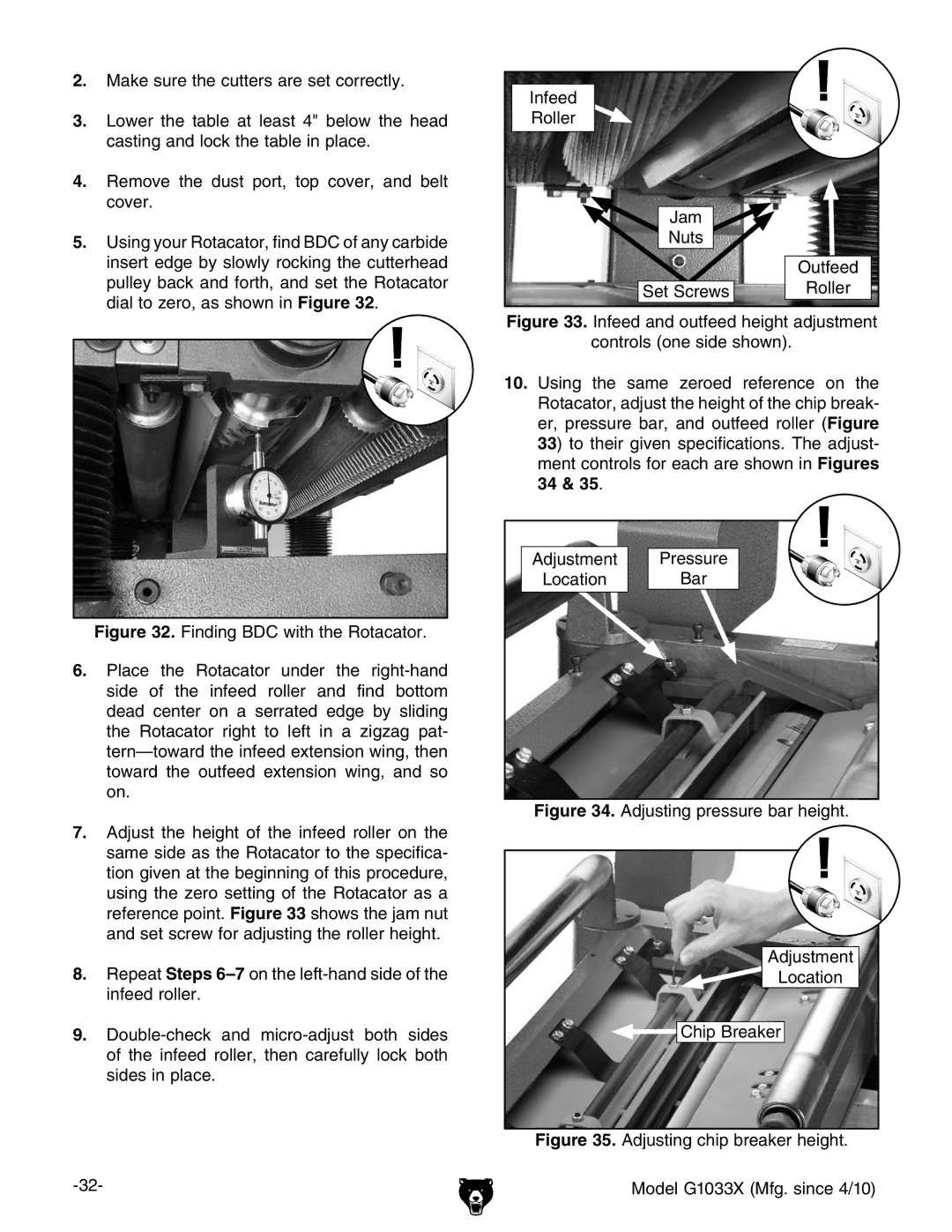

7.Adjust the height of the infeed roller on the same side as the Rotacator to the specifica- tion given at the beginning of this procedure, using the zero setting of the Rotacator as a reference point. Figure 33 shows the jam nut and set screw for adjusting the roller height.

8.Repeat Steps

9.

Infeed |

|

Roller |

|

Jam |

|

Nuts |

|

| Outfeed |

Set Screws | Roller |

Figure 33. Infeed and outfeed height adjustment

controls (one side shown).

10.Using the same zeroed reference on the Rotacator, adjust the height of the chip break- er, pressure bar, and outfeed roller (Figure 33) to their given specifications. The adjust- ment controls for each are shown in Figures 34 & 35.

Adjustment | Pressure |

Location | Bar |