SPINDLE SPEEDS

The Model G1131 features a

1.Turn off and unplug the drill press and allow all moving parts to stop.

2.Loosen the tensioning knob located just forward of the motor mount.

3.Open the top of the belt housing and reduce tension on the belts by pushing the motor toward the front of the drill press.

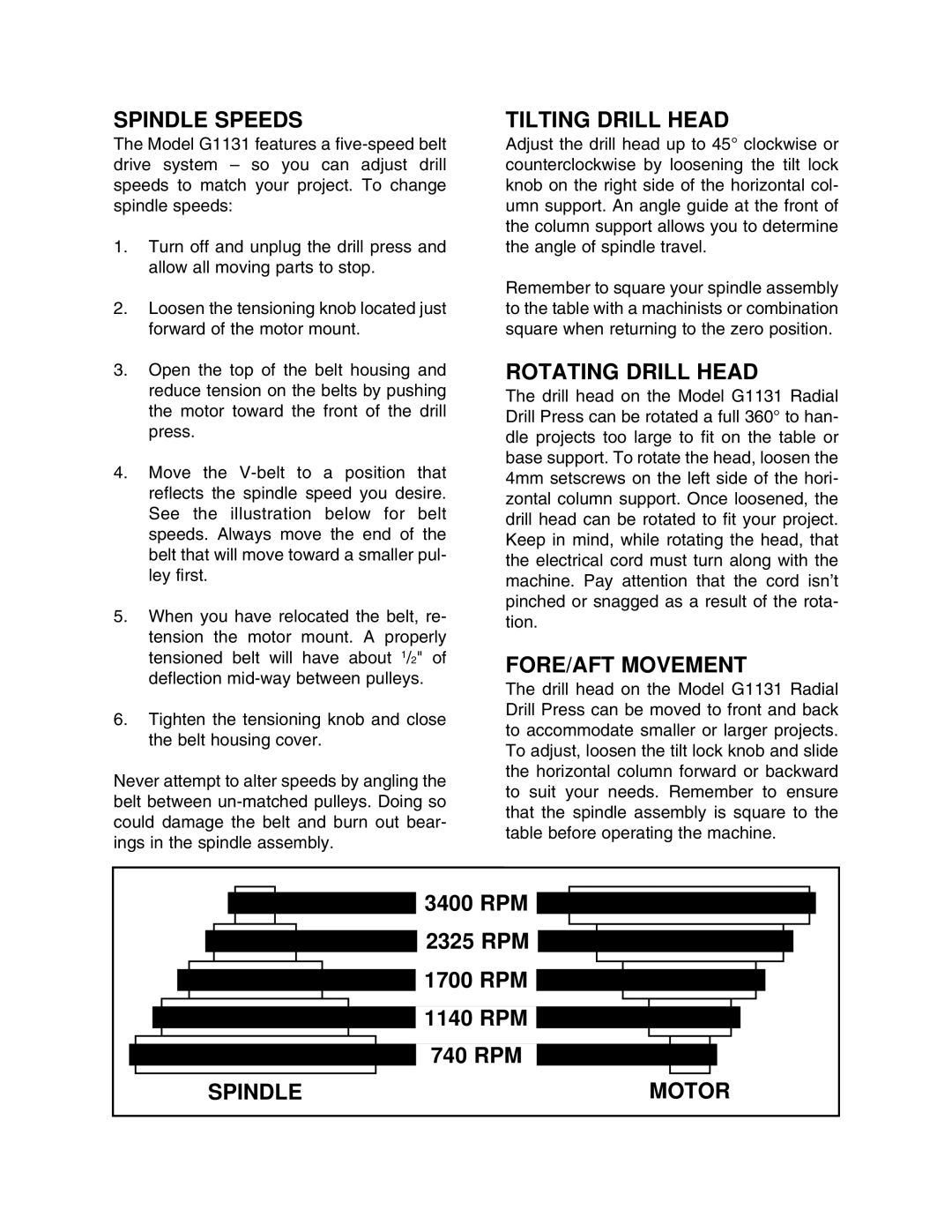

4.Move the

5.When you have relocated the belt, re- tension the motor mount. A properly tensioned belt will have about 1/2" of deflection

6.Tighten the tensioning knob and close the belt housing cover.

Never attempt to alter speeds by angling the belt between

TILTING DRILL HEAD

Adjust the drill head up to 45° clockwise or counterclockwise by loosening the tilt lock knob on the right side of the horizontal col- umn support. An angle guide at the front of the column support allows you to determine the angle of spindle travel.

Remember to square your spindle assembly to the table with a machinists or combination square when returning to the zero position.

ROTATING DRILL HEAD

The drill head on the Model G1131 Radial Drill Press can be rotated a full 360° to han- dle projects too large to fit on the table or base support. To rotate the head, loosen the 4mm setscrews on the left side of the hori- zontal column support. Once loosened, the drill head can be rotated to fit your project. Keep in mind, while rotating the head, that the electrical cord must turn along with the machine. Pay attention that the cord isn’t pinched or snagged as a result of the rota- tion.

FORE/AFT MOVEMENT

The drill head on the Model G1131 Radial Drill Press can be moved to front and back to accommodate smaller or larger projects. To adjust, loosen the tilt lock knob and slide the horizontal column forward or backward to suit your needs. Remember to ensure that the spindle assembly is square to the table before operating the machine.

3400 RPM

2325 RPM

1700 RPM

1140 RPM

740 RPM

SPINDLE | MOTOR |