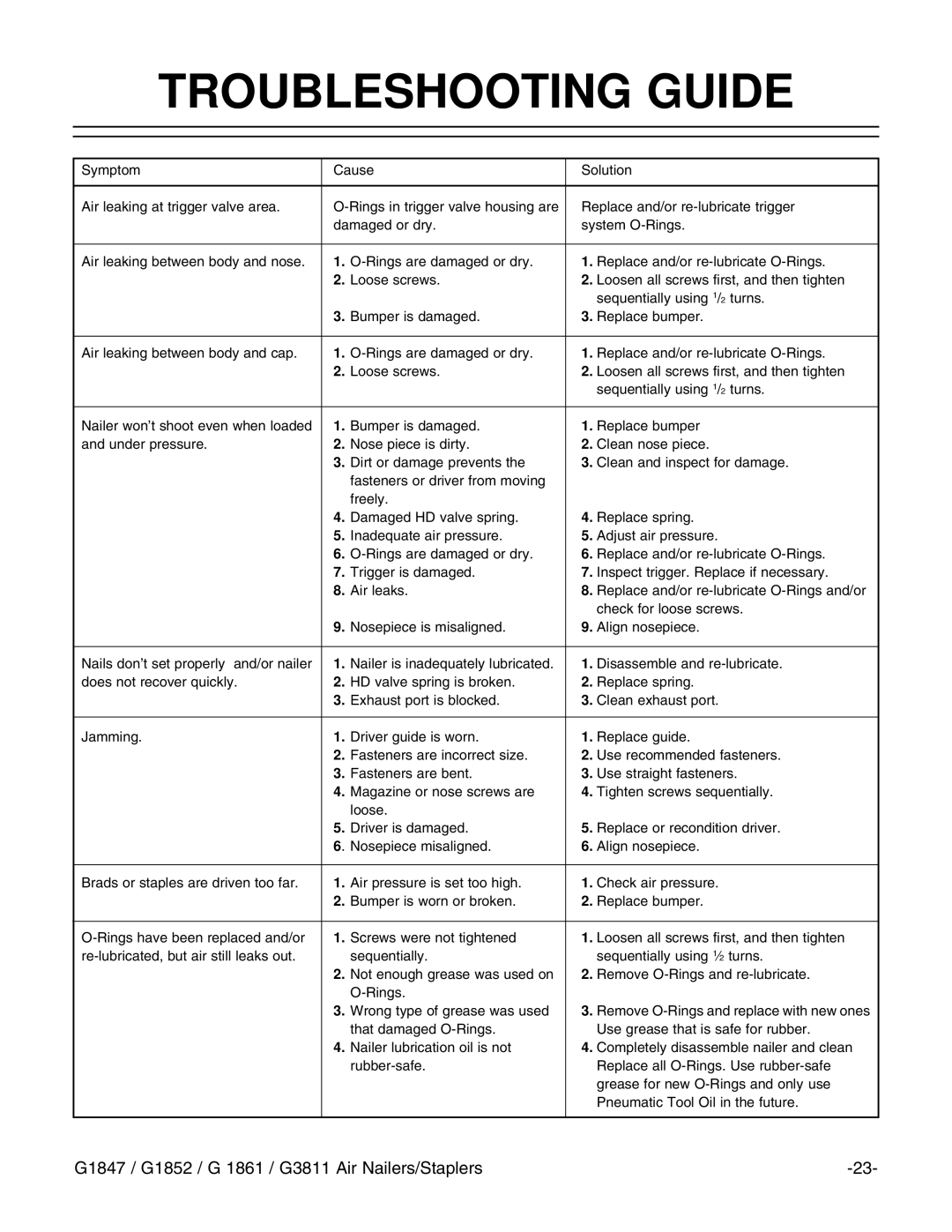

TROUBLESHOOTING GUIDE

Symptom | Cause | Solution | ||

|

|

| ||

Air leaking at trigger valve area. | Replace and/or | |||

| damaged or dry. | system | ||

|

|

|

| |

Air leaking between body and nose. | 1. | 1. | Replace and/or | |

| 2. | Loose screws. | 2. | Loosen all screws first, and then tighten |

|

|

|

| sequentially using 1/2 turns. |

| 3. | Bumper is damaged. | 3. | Replace bumper. |

|

|

|

| |

Air leaking between body and cap. | 1. | 1. | Replace and/or | |

| 2. | Loose screws. | 2. | Loosen all screws first, and then tighten |

|

|

|

| sequentially using 1/2 turns. |

|

|

|

| |

Nailer won’t shoot even when loaded | 1. Bumper is damaged. | 1. | Replace bumper | |

and under pressure. | 2. Nose piece is dirty. | 2. | Clean nose piece. | |

| 3. | Dirt or damage prevents the | 3. | Clean and inspect for damage. |

|

| fasteners or driver from moving |

|

|

|

| freely. |

|

|

| 4. | Damaged HD valve spring. | 4. | Replace spring. |

| 5. | Inadequate air pressure. | 5. | Adjust air pressure. |

| 6. | 6. | Replace and/or | |

| 7. | Trigger is damaged. | 7. | Inspect trigger. Replace if necessary. |

| 8. | Air leaks. | 8. | Replace and/or |

|

|

|

| check for loose screws. |

| 9. | Nosepiece is misaligned. | 9. | Align nosepiece. |

|

|

|

| |

Nails don’t set properly and/or nailer | 1. Nailer is inadequately lubricated. | 1. | Disassemble and | |

does not recover quickly. | 2. HD valve spring is broken. | 2. | Replace spring. | |

| 3. | Exhaust port is blocked. | 3. | Clean exhaust port. |

|

|

|

| |

Jamming. | 1. Driver guide is worn. | 1. | Replace guide. | |

| 2. | Fasteners are incorrect size. | 2. | Use recommended fasteners. |

| 3. | Fasteners are bent. | 3. | Use straight fasteners. |

| 4. | Magazine or nose screws are | 4. | Tighten screws sequentially. |

|

| loose. |

|

|

| 5. | Driver is damaged. | 5. | Replace or recondition driver. |

| 6. Nosepiece misaligned. | 6. | Align nosepiece. | |

|

|

|

| |

Brads or staples are driven too far. | 1. Air pressure is set too high. | 1. | Check air pressure. | |

| 2. | Bumper is worn or broken. | 2. | Replace bumper. |

|

|

|

| |

1. Screws were not tightened | 1. | Loosen all screws first, and then tighten | ||

| sequentially. |

| sequentially using 1⁄2 turns. | |

| 2. | Not enough grease was used on | 2. | Remove |

|

|

|

| |

| 3. | Wrong type of grease was used | 3. | Remove |

|

| that damaged |

| Use grease that is safe for rubber. |

| 4. | Nailer lubrication oil is not | 4. | Completely disassemble nailer and clean |

|

|

| Replace all | |

|

|

|

| grease for new |

|

|

|

| Pneumatic Tool Oil in the future. |

|

|

|

|

|

G1847 / G1852 / G 1861 / G3811 Air Nailers/Staplers |