Drilling Wood | Mortise Attachment | |

|

|

|

|

|

|

Twist bits, which are intended for metal, may also be used for boring holes in wood. Machine spur bits are generally preferred, they cut a square bottomed hole and are designed for removal of wood chips. Do not use hand bits which have a screw tip; at drill press speeds they turn into the wood too fast and tend to lift the workpiece off the table and spin it.

For through boring, line up the hole in the work table with the bit to avoid damaging its tip. Scribe a vertical line on the column and a matching line on the table bracket so the table can be clamped in the center position at any height. Use a piece of scrap wood under your workpiece and feed the bit into the wood slowly to prevent splintering the bottom side of the workpiece.

When using your drill press for operations such as shaping, sanding or mortising, use jigs, fix- tures or

The chuck will accept any tool with up to a 5⁄8" shank. Do not attempt to open the chuck wider by forcing it.

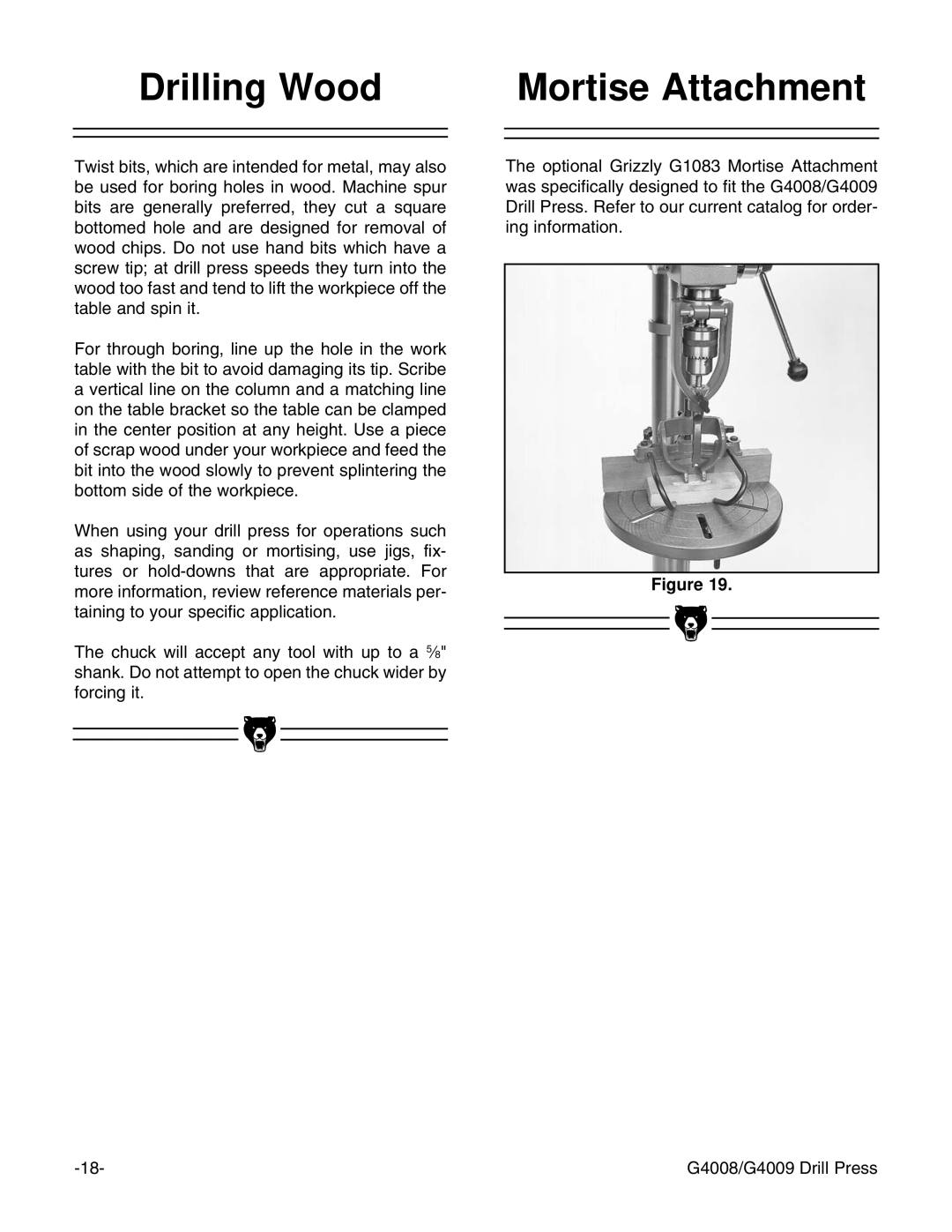

The optional Grizzly G1083 Mortise Attachment was specifically designed to fit the G4008/G4009 Drill Press. Refer to our current catalog for order- ing information.

Figure 19.

|

|

|

|

|

|

|

|

|

| G4008/G4009 Drill Press | |

|

|